Lewei's End-to-End NPI Solutions

Lewei Precision accelerates your new product introduction process, taking your ideas from concept to fully market-ready solutions.

- 20+ inspection equipment

- 140+ engineers

- 700+ ISO-certified manufacturing centers

Common Challenges in New Product Introduction

Launching a new product is a multi-stage journey, and many organizations encounter obstacles along the way. Below are the most frequent challenges:

Design-to-Production Mismatch

Innovative designs may not align with real-world manufacturing, causing expensive redesign cycles.

Material Knowledge Gaps

Teams often lack in-depth expertise with specialized materials and modern fabrication processes.

Inefficient Production Methods

Adapting manufacturing to meet evolving requirements while keeping costs low remains a hurdle.

Disconnected Supply Chains

Sourcing from multiple suppliers can create quality variations and timeline disruptions.

Assembly Stage Surprises

Critical issues discovered late in the build phase lead to bottlenecks and slower market launches.

Why Choose Our NPI Solutions

All-in-One Approach

Streamline your NPI journey with end-to-end support from rapid prototyping to final packaging. No vendor hassles, just faster launches.

Advanced Manufacturing Power

Our in-house facilities utilize 20+ processes to achieve complex geometries, ultra-tight tolerances, and premium finishes , enabling next-generation products.

Uncompromising Quality

ISO-certified systems, real-time production monitoring, and multi-level inspections ensure every part is accurate, compliant, and dependable.

Ready to Launch Your Next Product?

Lewei Precision’s NPI services simplify every phase of development. Avoid setbacks — request your instant quote today.

See How RapidDirect Accelerates NPI

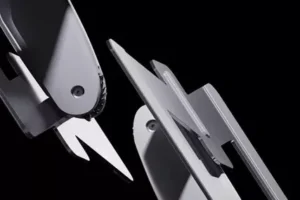

Rennteam Stuttgart Racecar: The University of Stuttgart

RapidDirect proudly supports Rennteam Stuttgart by manufacturing 2 mainbar components and over 80 Aluminum inserts.

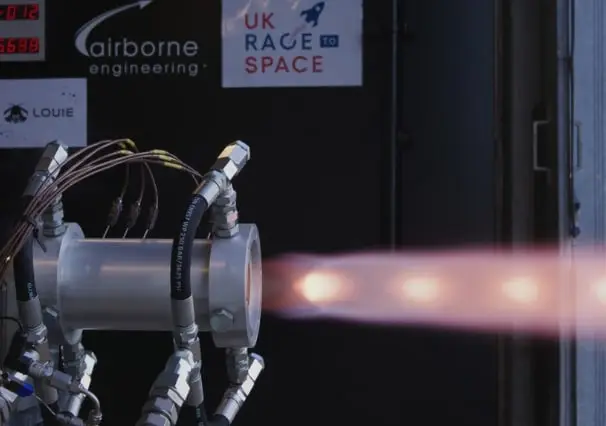

LURA: The Leeds University Rocket Association

RapidDirect’s 5-axis CNC turn-mill technques helps LURA produce engine parts, winning the National Race to Space Propulsion Competition.