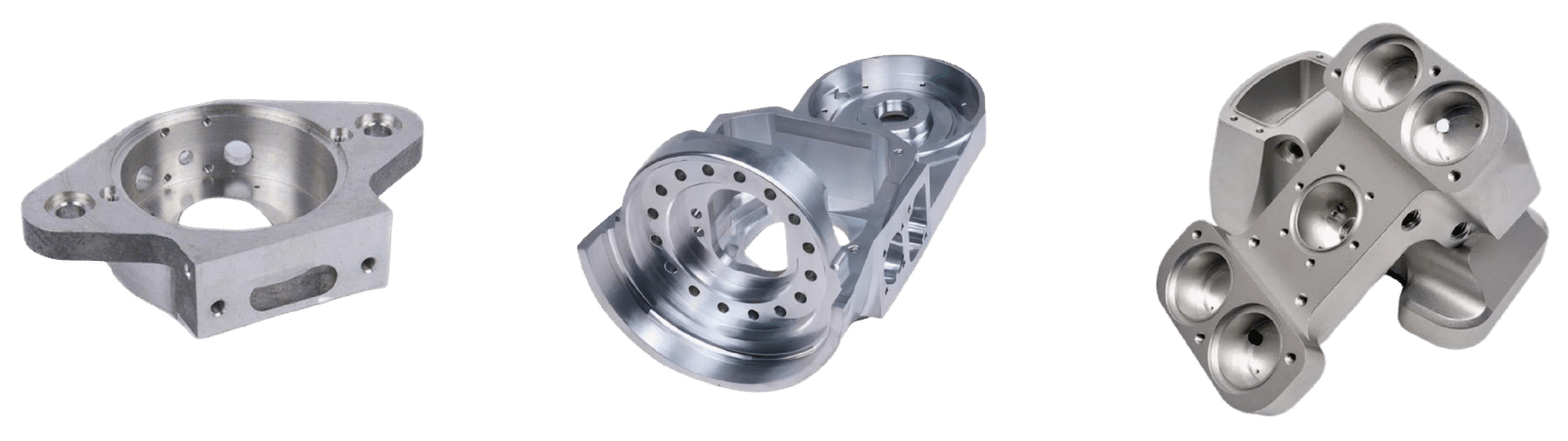

Custom 3D Printing Solutions

Receive instant online quotes for custom 3D printed components in both metal and plastic materials. Order precision prototypes and production parts with exceptional quality.

- Tolerances as fine as ±0.2 mm.

- ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified

- Lead time as fast as 1 day

Tailored 3D Printing Solutions

At Lewei Precision, our 3D printing services are crafted to suit your unique requirements. Whether you need rapid prototypes or large-scale production parts, we deliver high-quality, custom 3D printed components with unmatched precision. Using advanced technologies like SLA, HP MJF, SLS, and SLM, we ensure superior results with tolerances as tight as ±0.2 mm. Rely on our experts for high-resolution parts that adhere to your exact specifications.

SLA uses a laser to solidify liquid resin, creating parts with exceptional precision and smooth finishes. Perfect for producing detailed prototypes and complex designs.

HP MJF utilizes a fusing agent and heat to produce durable, high-performance parts with intricate details and outstanding mechanical properties.

SLS uses a laser to fuse powdered material layer by layer, creating strong, durable parts. Ideal for intricate geometries and functional end-use applications.

SLM uses a laser to melt metal powders, producing high-strength, detailed metal parts. Perfect for applications in aerospace, medical, and industrial sectors.

How Lewei Precision’s 3D Printing Services Work

Lewei Precision partners with a vast network of advanced 3D printing facilities to produce both intricate prototypes and large-scale production parts. Using a layer-by-layer printing process, we ensure each component is thoroughly inspected for dimensional accuracy and visual quality. Every custom 3D printed part meets your specific requirements, maintaining consistency across all your projects.

3D Printing Materials

We offer a wide range of materials, including plastics like ABS and PA (Nylon), as well as metals such as Aluminum and Stainless Steel, perfect for diverse industrial 3D printing applications. If you have specific material needs, select ‘Other’ on our quote configuration page, and we will source the exact material you require.

As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Copper is highly conductive and malleable, making it a top choice for electrical wiring and plumbing. Its natural antibacterial properties also make it ideal for medical applications, while its aesthetic appeal suits decorative items and artwork.

Red-orange

Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish

$$$

About 5 business days

Bronze, an alloy of copper and tin, is known for its durability and resistance to corrosion. It’s widely used in marine applications, sculptures, and bearings, thanks to its strength and ability to withstand harsh environments.

Metallic brown

Tin Bronze

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish

About 5 business days

Steel is a strong and versatile material, widely used in construction and manufacturing. Its high tensile strength makes it suitable for structural components, while various Subtypes enhance its properties for specialized applications, like tools and machinery.

Silver Grey

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

As machined, Electroplating, Passivation, Powder coating

About 7 business days

Stainless steel is resistant to rust and staining, making it perfect for kitchen appliances and medical equipment. Its strength and aesthetic appeal also make it a popular choice for architectural designs and automotive parts.

Silver Grey

Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

As machined, Electroplating, Passivation, Powder coating

ABout 7 business days

Magnesium is lightweight yet strong, often used in aerospace and automotive applications where reducing weight is critical. Its machinability allows for complex shapes, and it’s also utilized in various electronic devices for its excellent conductivity.

White-silver

Magnesium Alloy AZ31B, AZ91D

As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis

ABout 8 business days

Titanium is incredibly strong and lightweight, making it ideal for aerospace and medical implants. Its resistance to corrosion and biocompatibility enhance its use in demanding environments, while its high strength-to-weight ratio suits various industrial applications.

Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish

ABout 8 business days

3D Printing Post Processing

Post-processing enhances 3D prints with six precise surface finishes: smooth, glossy, matte, textured, polished, and anodized. These finishes improve both the appearance and durability of parts, making them ideal for functional or visible components. For internal or rough prototypes, post-processing may be unnecessary where aesthetics are not a priority.

Perfect for functional prototypes or internal parts where aesthetics are not crucial.

Improves appearance and longevity with a range of color choices and protective finishes.

Minimizes roughness, creating a smoother and more aesthetically pleasing surface for visible parts.

Creates a protective oxide layer on metal parts, offering corrosion resistance and the option for vibrant colors and surface durability.

Applies a metal coating to enhance strength, wear resistance, and conductivity, perfect for functional and high-durability parts.

Adds a custom pattern or texture to the surface, providing grip or a unique aesthetic, ideal for tactile components.

3D Printing Services

3D-Druck

Kick off your project with our quick and efficient 3D printing service. Perfect for producing detailed prototypes and custom parts, we leverage cutting-edge technologies to provide high-quality, high-resolution prints with precise tolerances.

- Quickly iterate and refine your designs to achieve flawless results.

Vakuumgießen

Our urethane casting service offers an efficient solution between prototyping and full-scale production. Ideal for low to medium-volume runs, it produces durable, high-quality parts with exceptional surface finish and detail.

- Perfect for market testing and initial product launches.

Spritzgießen

For high-volume production, our injection molding service is the ideal solution. It efficiently produces large quantities of parts while ensuring consistent quality and precision.

- A cost-effective method for large-scale production.

Lewei Precision 3D Printing Capabilities

We offer a detailed guide to each 3D printing process, highlighting its unique standards to help you make informed decisions for your printing requirements.Our CNC machines operate with precision tolerances that meet industry standards, ensuring that every part is consistently accurate and fits perfectly with other components.

Feature | SLA | MJF | SLS | SLM |

Min. Wall Thickness | 0.6mm for unsupported walls, 0.4mm for supported walls on both sides | At least 1mm thick; avoid overly thick walls | From 0.7mm (PA 12) to 2.0mm (carbon-filled polyamide) | 0.8 mm |

Layer Height | 25 µm to 100µm | Around 80µm | 100–120 microns | 30 – 50μm |

Max. Build Size | 1400x700x500mm | 264x343x348mm | 380x280x380mm | 320x320x400mm |

Dimension Tolerance | ±0.2mm (For >100mm, apply 0.15%) | ±0.2mm (For >100mm, apply 0.25%) | ±0.3mm (For >100mm, apply 0.35%) | ±0.2mm (For >100mm, apply 0.25%) |

Fast Online 3D Printing Services

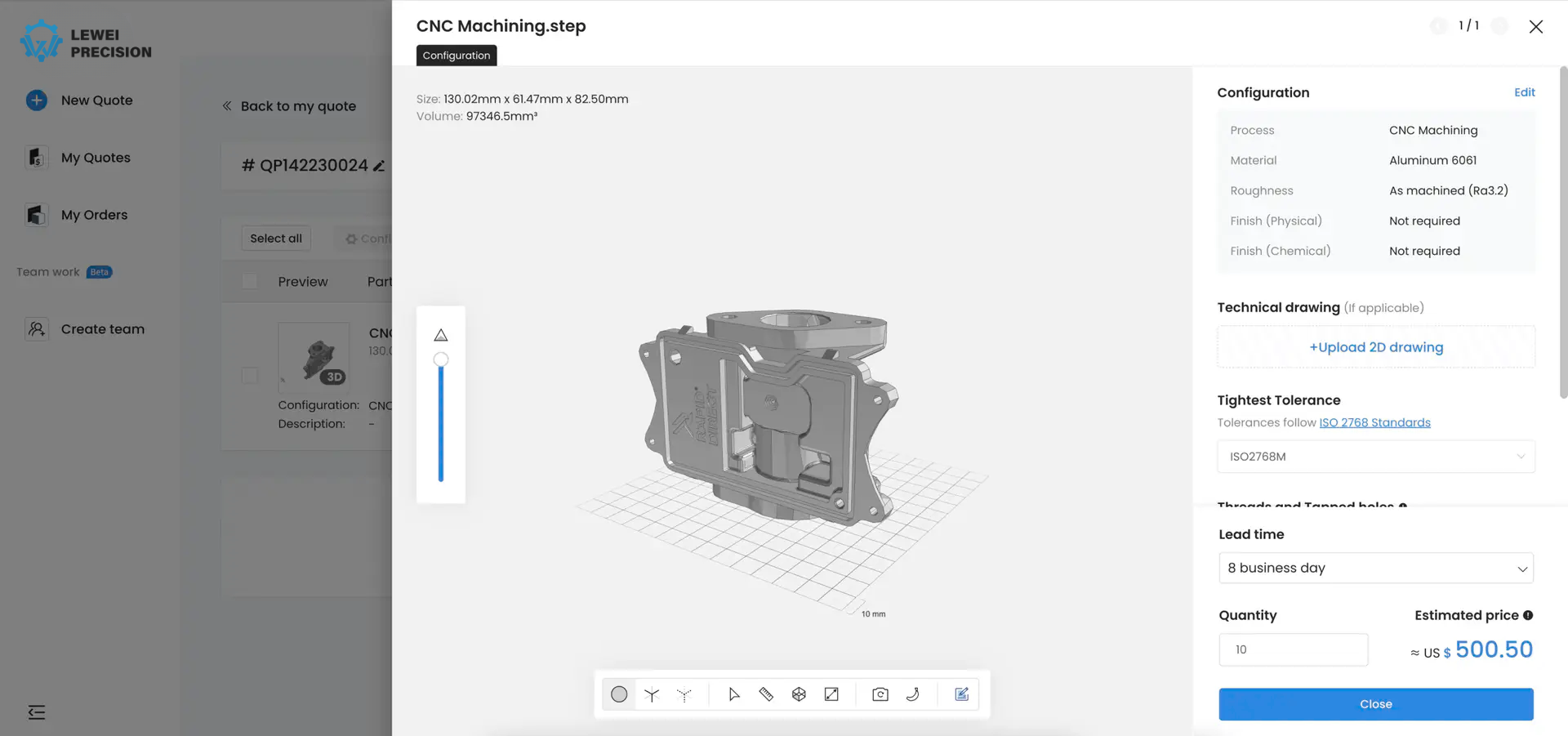

Need 3D printed parts in a hurry? Simply upload your 3D model files in formats like [.STP], [.STEP], or [.STL] for seamless processing. Our platform quickly analyzes your design to provide an instant, custom quote for optimal manufacturability.

Select from a wide range of materials and finishes, with guidance from our experts to ensure the best balance of cost, functionality, and aesthetics. Using high-resolution 3D printers, we bring your designs to life with exceptional precision. Every print undergoes strict inspection to ensure it meets your specifications. Enjoy fast delivery, with high-quality prints arriving as soon as the next day.

3D Printing for Diverse Industries

We cater to industries such as automotive, aerospace, and healthcare, offering tailored 3D printing solutions to meet the unique needs of each sector.

Why Choose Us

High-Resolution 3D Prints

With advanced materials, state-of-the-art technology, and strict quality control, we ensure durable, precise products that minimize rework and boost your project’s success.

With optimized processes and advanced equipment, we meet your urgent needs by delivering high-quality 3D prints quickly, reducing wait times and accelerating your project’s progress.

Our team of experienced engineers offers personalized guidance for every project, solving complex design challenges to ensure print success and customer satisfaction, tailored to your specific requirements.

What’s 3D Printing?

3D printing, or additive manufacturing, is an innovative technology that builds three-dimensional objects from digital files. The process adds material layer by layer until the final shape is achieved. Unlike traditional manufacturing, which often cuts away material from a larger block, 3D printing enables the creation of complex geometries and fine details with minimal waste. It’s widely used across industries, including prototyping, product development, medical implants, and aerospace. With its advantages in customization, speed, and cost-effectiveness, 3D printing is a key tool in modern manufacturing.

Advantages

Advantages of 3D Printing

3D printing offers numerous benefits over traditional manufacturing methods:

- Customization:Easily produce custom parts without added cost or complexity, perfect for personalized solutions.

- Complex Geometries: Create intricate designs and features that traditional methods can’t achieve, enabling advanced functionality.

- Reduced Waste: Only the necessary material is used, minimizing waste compared to subtractive manufacturing.

- Rapid Prototyping: Quickly develop prototypes to test design, fit, and function, accelerating the development process.

- Cost-Effective for Small Runs: Ideal for low-volume production, saving on tooling and molds.

- Speed to Market: Shorten production lead times, enabling faster iteration and quicker product launches.

Applications

Custom 3D Printing Applications

3D printing enables a wide array of applications for various types of parts:

- Prototypes: Quickly transform design concepts into functional and visual prototypes.

- Custom Tools & Fixtures: Manufacture production-specific tools and jigs to enhance efficiency.

- Medical Implants: Create custom implants and prosthetics, ensuring a better fit and improved comfort.

- End-Use Parts: Produce ready-to-use parts for a variety of applications.

- Architectural Models: Design detailed models for planning and visualization.

- Customized Consumer Goods: Craft unique items like jewelry, phone cases, and home decor.

- Educational Models: Develop precise models for research and educational purposes.

CNC Machining FAQs

How long does it take to receive a 3D printed part from Lewei Precision?

What industries does Lewei Precision serve with 3D printing?

Lewei Precision provides tailored 3D printing solutions for a variety of industries, including automotive, aerospace, healthcare, and consumer goods. We work closely with each sector to meet their unique needs and provide high-quality, customized parts.

Can I get a prototype 3D printed before moving to full production?

Yes! Our 3D printing services are ideal for rapid prototyping. You can create functional and visual prototypes to test your designs before moving to full production. This allows you to evaluate fit, function, and design, saving you time and resources in the long run.

How do you ensure the quality of 3D printed parts?

Each 3D printed part undergoes strict inspection to ensure it meets your specifications. We use advanced quality control measures to check for dimensional accuracy and visual quality, ensuring that every part we produce meets the highest standards.