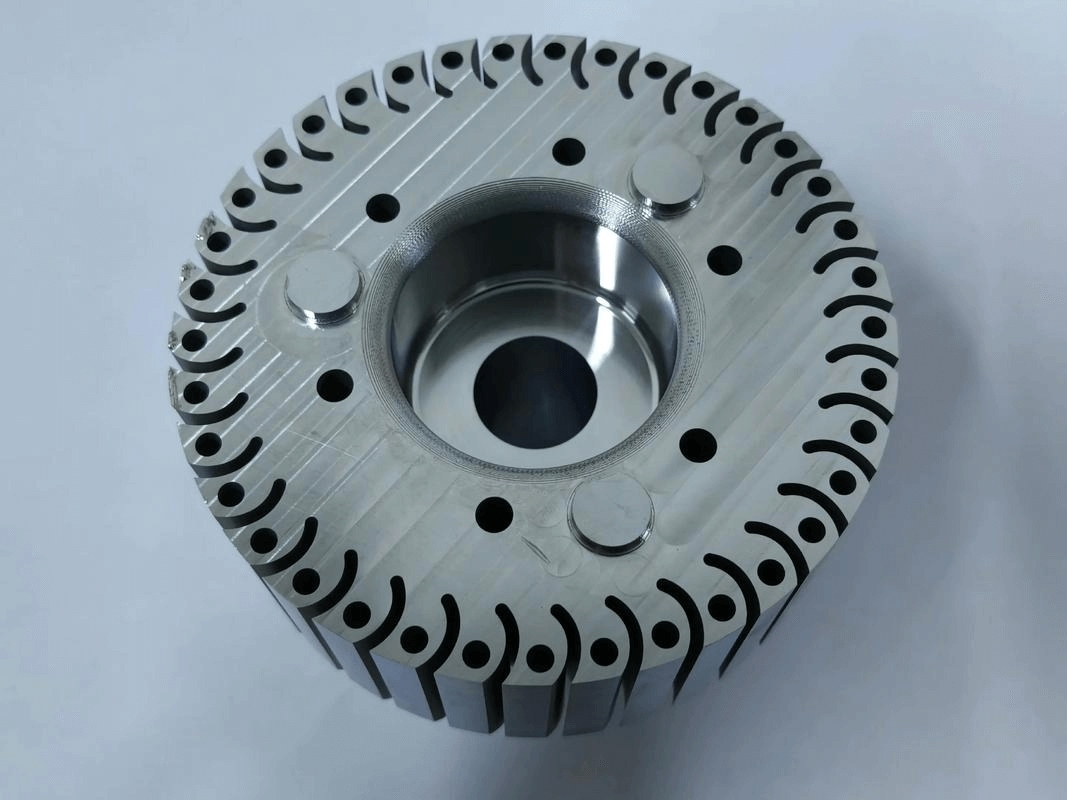

Our Wire EDM (Electrical Discharge Machining) service provides intricate, high-precision cuts on hard metals, ideal for complex designs with tight tolerances.

We utilize advanced, regularly maintained Wire EDM machines, guaranteeing clients receive components manufactured to the highest levels of precision and accuracy. Exceptional precision with tolerances up to ±0.001”.

Lewei delivers rapid project turnarounds in as little as 1 day without sacrificing quality, thanks to our streamlined Wire EDM process and skilled engineering team.

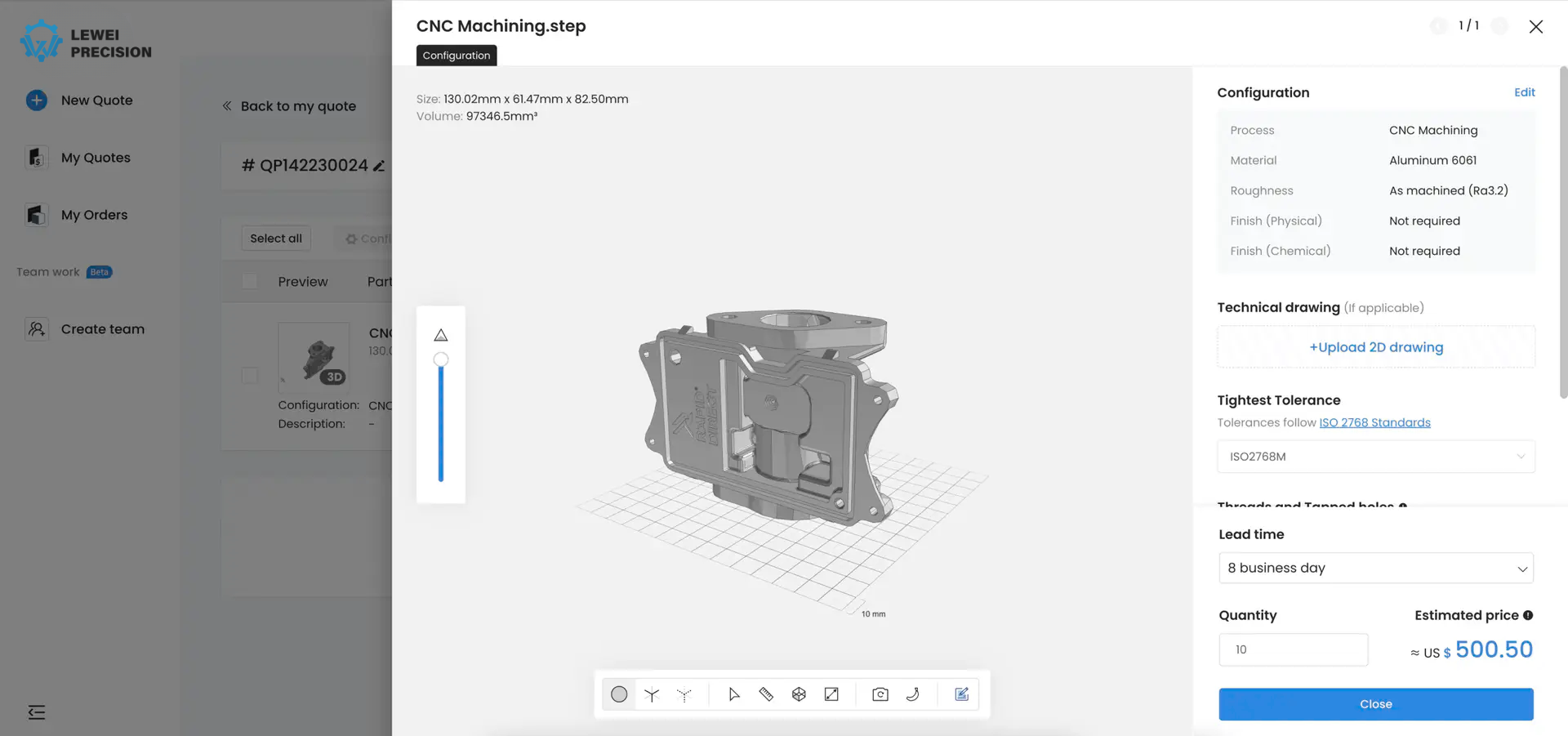

Lewei’s online platform provides fast quotes and real-time order updates. Simplify your projects with our efficient, transparent system for ultimate convenience in the digital era.

At Lewei, we harness the power of Wire Electrical Discharge Machining (EDM) to deliver precision-engineered components to our clients. Wire EDM is a highly specialized process that employs controlled electrical sparks to create intricate shapes and details in metals. This is achieved by generating a regulated electrical discharge between two electrodes submerged in dielectric fluid, which melts and vaporizes the metal with exact precision.

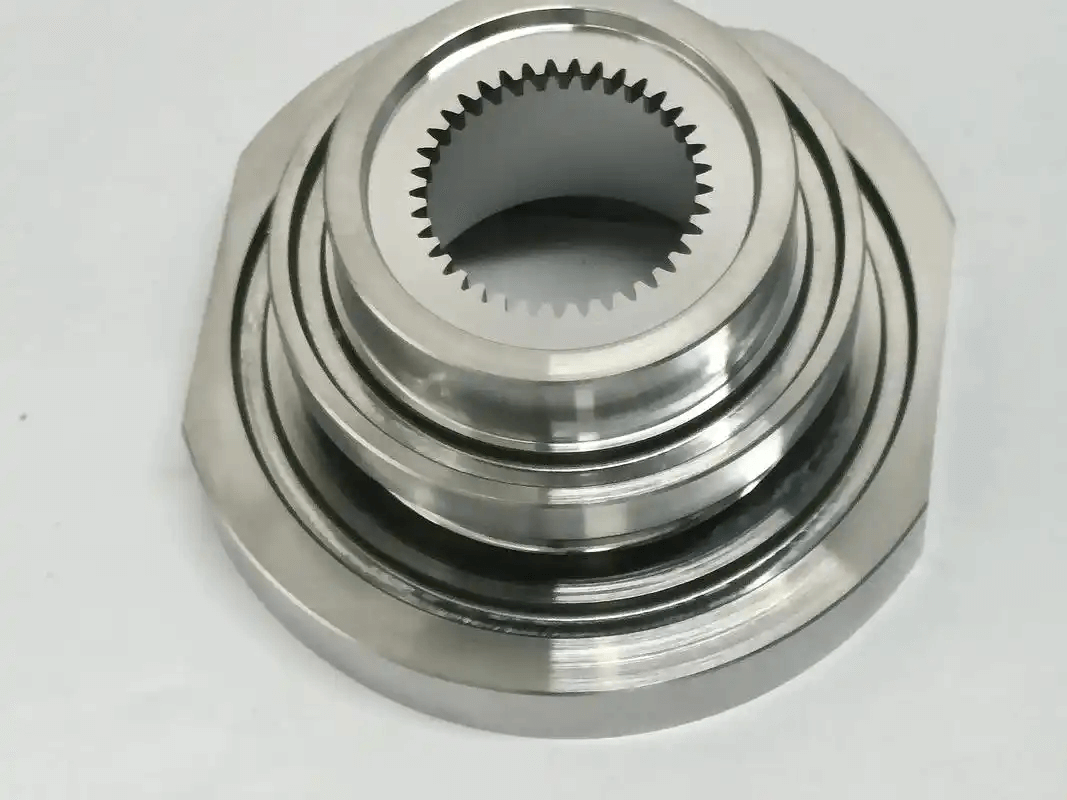

The true advantage of wire EDM lies in its capability to machine complex contours and fine details in materials that are difficult to process with traditional CNC machining. This includes heat-treated steels, superalloys, and other specialized metals. Wire EDM enables parts with extremely tight tolerances and fine features, such as narrow slots and small holes, with unmatched accuracy. Our services suit applications demanding high precision, including aerospace components, automotive parts, and detailed molds and dies. Lewei combines advanced wire EDM equipment with skilled technicians to ensure every cut meets exacting standards, making us a leader in wire EDM machining.

Machining Works

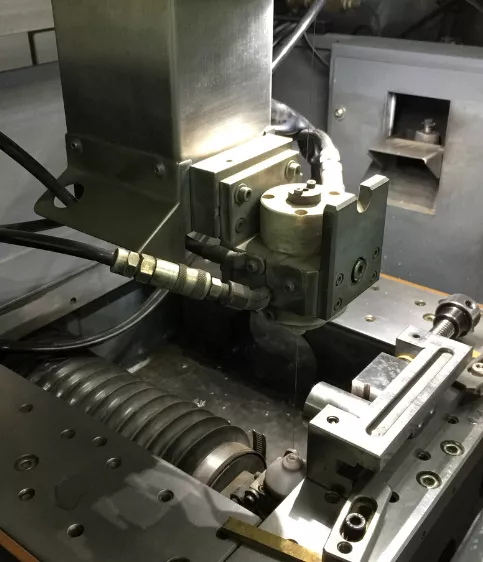

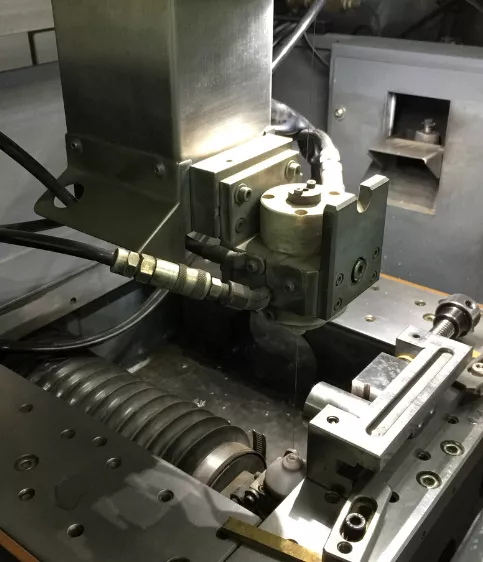

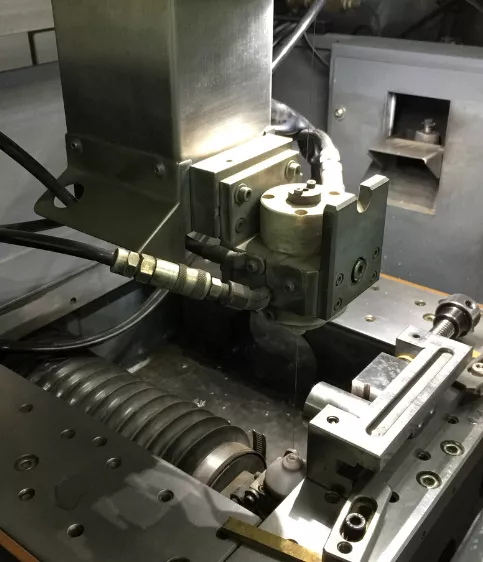

In wire EDM machining (Wire Electrical Discharge), a thin wire, precisely guided by computer systems, passes through a workpiece submerged in deionized water. Acting as both guide and electrode, the wire uses controlled electrical discharges to cut conductive materials with high accuracy, producing parts with finely finished surfaces that rarely need additional processing. Lewei’s state-of-the-art facilities ensure that even the most intricate designs are machined with precision, demonstrating our commitment to quality and customer satisfaction.

The first step is to firmly secure the workpiece onto the EDM machine’s worktable, making sure it stays completely stationary. The surface is then carefully cleaned and degreased to eliminate any contaminants. It is essential that the workpiece material is conductive, since wire EDM relies on a conductive medium to operate effectively.

Next, a fine metal wire is threaded through the machine’s guides while both the wire and workpiece are submerged in a dielectric fluid, typically deionized water. An electrical voltage is applied, causing the fluid to ionize and permitting an electrical discharge (spark) to occur, gradually eroding the surface of the workpiece.

The final step involves accurately controlling the wire’s motion using a computer numerical control (CNC) system. The CNC directs the wire along a defined path, allowing it to cut intricate shapes and profiles into the workpiece. The dielectric fluid circulates continuously to clear debris and regulate temperature during cutting. After completion, the workpiece is extracted, producing a high-quality, precisely finished part.

Lewei Precision’s Wire EDM services accurately machine a variety of conductive materials, including hardened steels and superalloys, delivering precise, durable components for critical applications.

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

At Lewei, we handle a wide spectrum of part sizes with our wire EDM services, from intricate micro components to larger, complex assemblies, ensuring every part meets precise dimensional standards.

Part Size | Small Parts (mm) | Medium Parts (mm) | Large Parts (mm) |

Maximum Length | 50 | 100 | 500 |

Maximum Width | 30 | 70 | 300 |

Maximum Height | 10 | 40 | 150 |

Minimum Thickness | 0.5 | 1.0 | 5.0 |

Tolerance | ±0.005 | ±0.01 | ±0.03 |

Lewei Precision partners with a network of advanced machine shops equipped with state-of-the-art wire EDM technology, providing high capacity for both simple and complex parts. Backed by ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 certifications, we ensure every part meets strict quality standards. Request your quote today and experience precision without compromise.

Wire EDM machining combines precision and versatility, delivering high-quality components across multiple industries.

Wire EDM provides multiple benefits for high-precision manufacturing:

Wire EDM uses electrical discharges to cut materials with extreme precision. This enables tolerances as tight as ±0.0001 inches, ideal for high-accuracy parts in critical industries.

Lewei Precision can machine conductive materials like titanium, stainless steel, tool steels, and aluminum. This versatility makes it suitable for aerospace, automotive, and medical devices.

Wire EDM is ideal for creating intricate geometries and sharp internal corners. It’s perfect for complex designs requiring fine details, such as those needed in medical and aerospace industries.

Wire EDM allows for the creation of detailed, intricate shapes without mechanical stress or distortion. It’s perfect for high-tolerance parts made from hard materials, often used in critical applications.

A machining center is a highly advanced CNC machine designed to handle a variety of machining tasks including milling, drilling, and tapping, all within a single setup. This integration enhances efficiency and accuracy by reducing the need to transfer parts between different machines. Machining centers are equipped with a tool turret or magazine that holds multiple tool options, enabling automatic tool changing under CNC control. This capability allows for switching between operations, optimizing production flow. Typically, machining centers are used for complex parts that require precision machining from multiple angles, making them indispensable in modern manufacturing environments.

Prompt response guaranteed within 12 hours