Custom Injection Molding Services

- T1 sample as fast as 2 weeks

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

- Fast, reliable production with high-quality results every time

Mit unseren fachkundigen Prototyping-Dienstleistungen können Sie Ihre Produktideen schnell und präzise zum Leben erwecken.

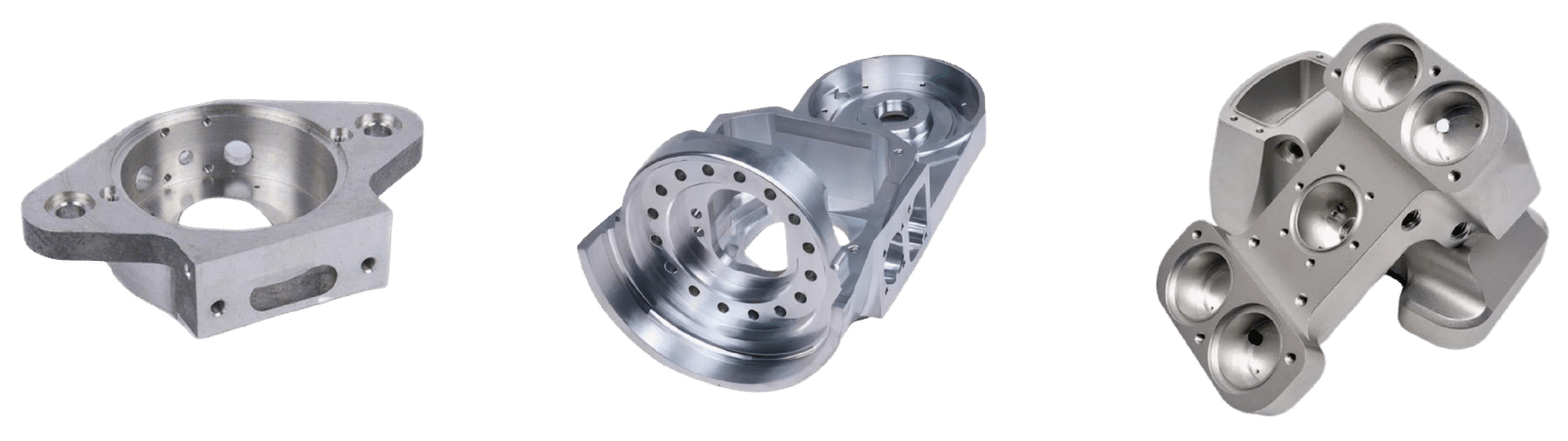

Custom Plastic Injection Molding for Precision Parts

Lewei Precision offers custom injection molding solutions for both prototypes and large-scale production. With our range of 90 to 830-ton machines, we produce high-quality plastic parts, no matter the size or complexity. Count on us for expert guidance throughout the design-to-production process, ensuring smooth and efficient project execution.

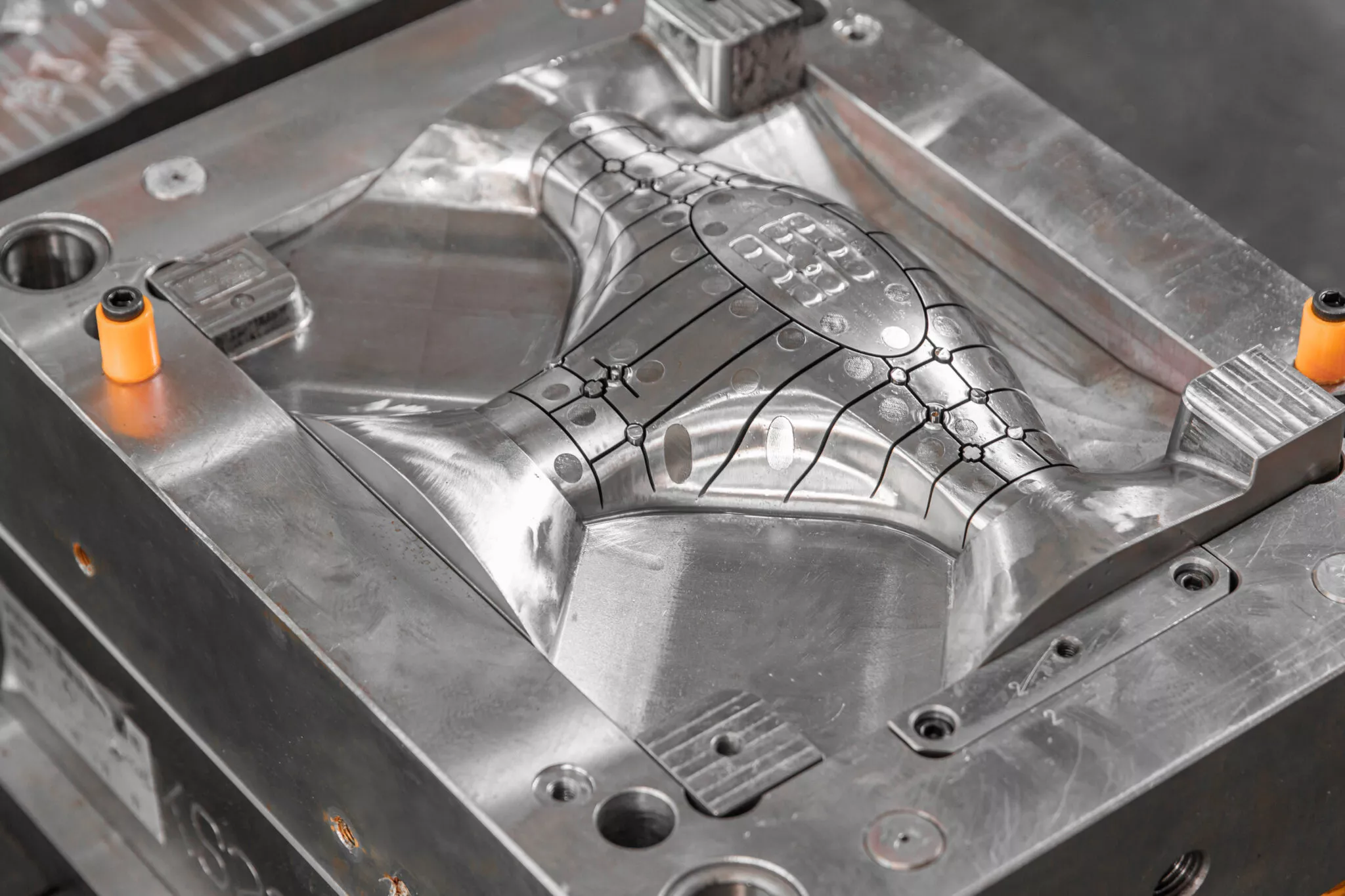

Lewei Precision offers high-performance aluminum and steel molds, achieving tight tolerances of 0.0008 inches (0.02 mm) with free mold flow analysis.

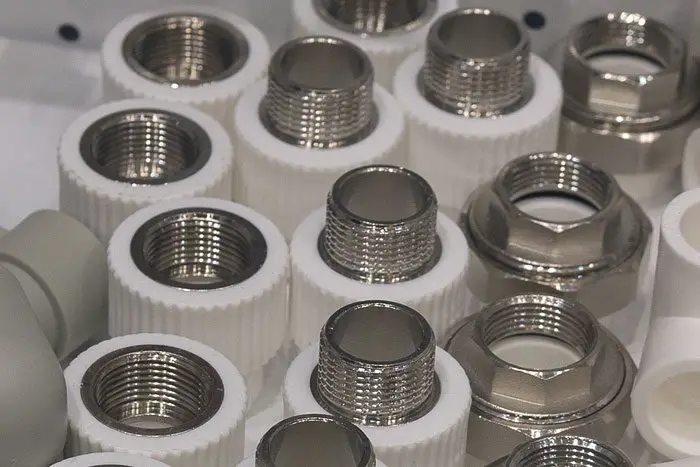

Our overmolding process bonds plastic to other components, creating durable, integrated parts with customizable color and texture options.

Insert molding combines engineering plastics with pre-placed inserts, eliminating fasteners and improving part strength and assembly efficiency.

Our Injection Molding Manufacturing Network

Lewei Precision’s expansive network, featuring over 50 advanced machines handling up to 830 tons, efficiently manages projects from prototypes to large-scale production. Each project starts with a comprehensive injection mold quote to set clear expectations. Our expert project managers offer detailed manufacturing analysis and consultative design services to enhance cost efficiency and functionality.

Injection Molding Materials

As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Copper is highly conductive and malleable, making it a top choice for electrical wiring and plumbing. Its natural antibacterial properties also make it ideal for medical applications, while its aesthetic appeal suits decorative items and artwork.

Red-orange

Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish

$$$

About 5 business days

Bronze, an alloy of copper and tin, is known for its durability and resistance to corrosion. It’s widely used in marine applications, sculptures, and bearings, thanks to its strength and ability to withstand harsh environments.

Metallic brown

Tin Bronze

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish

About 5 business days

Steel is a strong and versatile material, widely used in construction and manufacturing. Its high tensile strength makes it suitable for structural components, while various Subtypes enhance its properties for specialized applications, like tools and machinery.

Silver Grey

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

As machined, Electroplating, Passivation, Powder coating

About 7 business days

Stainless steel is resistant to rust and staining, making it perfect for kitchen appliances and medical equipment. Its strength and aesthetic appeal also make it a popular choice for architectural designs and automotive parts.

Silver Grey

Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

As machined, Electroplating, Passivation, Powder coating

ABout 7 business days

Magnesium is lightweight yet strong, often used in aerospace and automotive applications where reducing weight is critical. Its machinability allows for complex shapes, and it’s also utilized in various electronic devices for its excellent conductivity.

White-silver

Magnesium Alloy AZ31B, AZ91D

As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis

ABout 8 business days

Titanium is incredibly strong and lightweight, making it ideal for aerospace and medical implants. Its resistance to corrosion and biocompatibility enhance its use in demanding environments, while its high strength-to-weight ratio suits various industrial applications.

Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish

ABout 8 business days

Injection Mold Surface Finishes

Lewei Precision provides SPI surface finishes for injection molded parts, tailored to your project’s requirements. Our experts are ready to guide you in selecting the ideal finish.

Provides a smooth, high-gloss surface for parts requiring superior aesthetic appeal and visual quality.

Creates a matte, durable surface that enhances grip and hides fingerprints, often used in industrial parts.

Achieves a uniform, matte surface with texture, ideal for better handling or improved assembly.

Uses abrasive media to refine surfaces, offering a smooth or matte finish for complex parts.

Applies a highly reflective, durable layer for corrosion resistance, commonly used in automotive and decorative parts.

Engraves intricate patterns or designs on parts for precise logos, textures, and unique markings.

Tolerances for CNC Machining

Eigenschaften | Description |

Maximum Part Size | 1200 × 1000 × 500 mm |

Minimum Part Size | 5 × 5 × 5 mm |

Part to Part Repeatability | ±0.1 mm |

Mold Cavities | Single-cavity, multi-cavity, family molds |

Available Mold Types | Steel and aluminum molds, suitable for varying production levels |

Production Levels | Below 1000, 5000, 30000, and over 100000 units |

Mold Cavity Tolerances | ±0.02 mm |

Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts, and assembly |

Undercuts | Y-type, L-type undercuts |

Wall Thickness | 0.5 mm to 5 mm |

Draft | 0.5° to 2° |

Ribs/Gussets | 0.5 mm to 3 mm thick |

Bosses | Diameter 3 mm to 10 mm |

Lead Time | Most orders completed within 15 working days |

Design Guidelines for CNC Machining

Eigenschaften | Description |

Wall Thickness | Uniform thickness of 1.5 mm to 3 mm is recommended. Avoid excessively thick or thin walls to prevent warping. |

Radii and Corners | Minimum radius of 0.5 mm for internal corners. Avoid sharp corners to reduce stress points and aid in mold release. |

Draft Angles | Draft angle of 1° to 2° is recommended on vertical walls to ensure smooth part ejection. |

Undercuts | Use side actions or lifters to accommodate undercuts. Proper mold design is necessary for parts with undercuts. |

Tolerances | Standard tolerance of ±0.1 mm. For tighter tolerances (±0.01 mm), specialized molds are required. |

Text and Logos | Minimum engraving depth of 0.1 mm and width of 0.5 mm. CNC engraving or laser marking is used for text/logo creation. |

Holes and Features | Minimum hole diameter of 1.5 mm. For holes larger than 5 mm, inserts or core pins are recommended. |

Parting Line and Gate | Gates should be placed to minimize defects, and parting lines should be positioned in non-visible areas. |

Material Selection | Choose appropriate materials such as ABS, polycarbonate, or nylon, depending on the part’s intended use. |

Injection Molding Design Guide

Commitment to Unmatched Quality in Plastic Injection Molding

We are dedicated to delivering top-tier plastic injection molded components by maintaining rigorous quality standards at every stage of production. From the very first design phase through to the final product inspection, our goal is to ensure every part is crafted with utmost precision and reliability.

Our process begins with a detailed Design for Manufacturability (DFM) review, where our team works closely with clients to refine designs and optimize them for molding, minimizing potential issues in production.

With ISO 9001:2015 certification, and a commitment to continuous improvement, Lewei Precision ensures the highest standards of quality across every product we manufacture.

- Certifications: ISO 9001:2015, ISO 13485, ISO 14001, IATF 16949

- Experienced team of quality engineers

- State-of-the-art inspection equipment

Prototyping Injection Molding

Get custom plastic prototypes and production parts with flexible solutions from Lewei Precision.

Lewei Precision offers rapid prototyping services for injection molding, delivering high-quality prototypes with quick lead times. We provide flexible material options and expert DFM assistance to help you test functionality and validate designs efficiently.

- Quantity: 1-100 pcs

- Lead Time: 1-3 weeks

- Tooling: Soft tooling or 3D-printed molds

- Key Features: Low-volume, high-quality plastic parts

- Quantity: 1-100 pcs

- Lead Time: 1-3 weeks

- Soft tooling or 3D-printed mold used

Lewei Precision’s low-volume injection molding uses aluminum tooling to produce complex plastic parts quickly and cost-effectively. This service is perfect for design validation, inventory control, and a supply chain capable of adapting to fluctuating demand.

- Quantity: 100-10,000 pcs

- Lead Time: 3-6 weeks

- Key Features: Fast, cost-efficient production of low-volume plastic parts

High-volume injection molding provides a reliable and affordable solution for mass-producing identical, precise parts. With state-of-the-art equipment and rigorous quality control, we ensure tight tolerances and consistent quality across a range of plastic materials to suit your requirements.

- Quantity: Over 10,000 pcs, can scale into the millions

- Lead Time: 4-12 weeks or more

- Materials Available: 100+ thermoplastic and thermoset materials

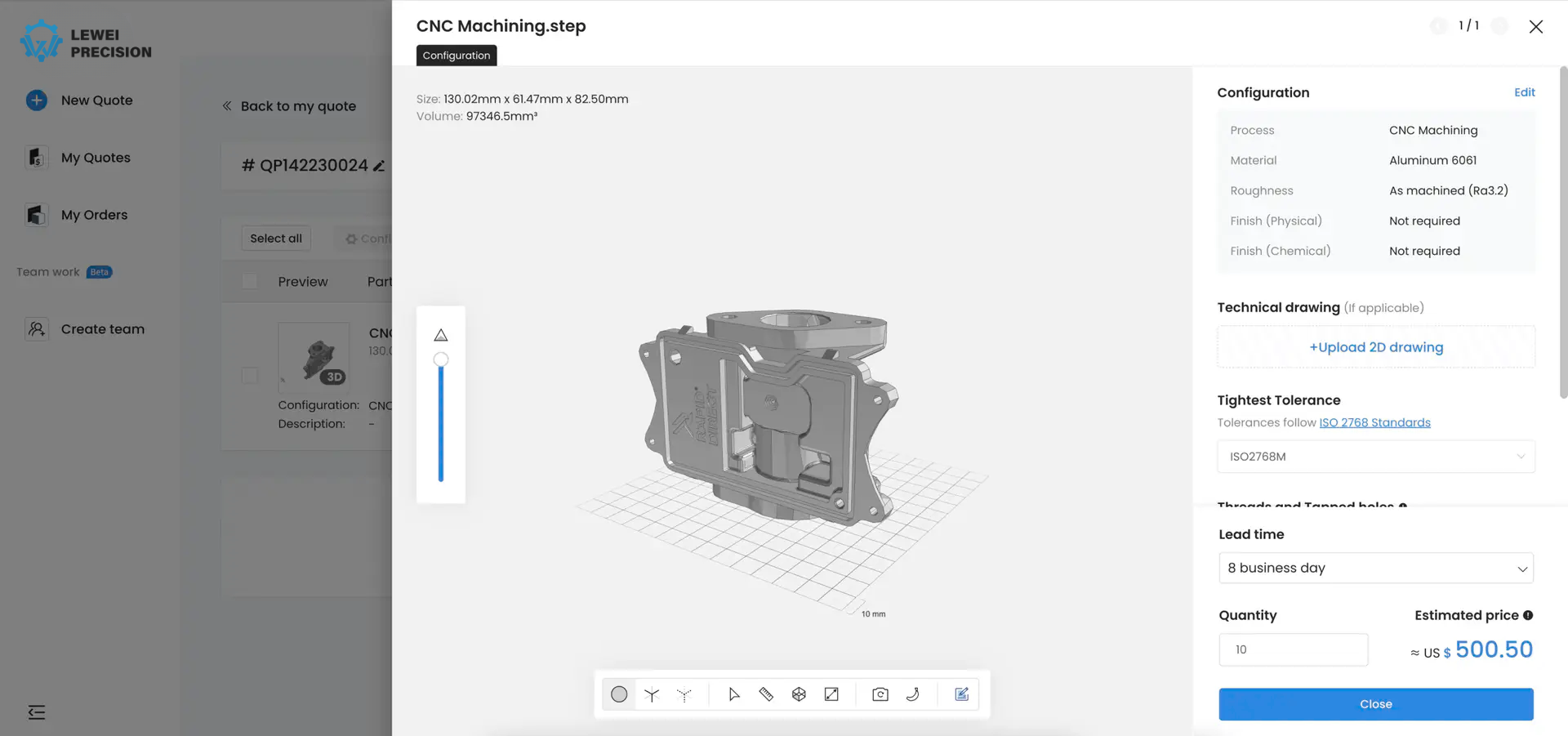

Start Your CNC Machining Project

Comprehensive Injection Molding Solutions for Diverse Industries

Lewei Precision offers tailored injection molding services to meet the unique needs of various industries, ranging from automotive to electronics. Our commitment to precision and cost-effectiveness ensures that we provide high-quality, custom solutions for every application.

Success Stories of

Lewei Precision x Rennteam Stuttgart: Innovation Collaboration of Racecar Engineering

Lewei Precision proudly supports Rennteam Stuttgart by manufacturing 2 mainbar components and over 80 Aluminum inserts. Our precision engineering ensures they’re ready to conquer the Formula Student competitions, giving the team a winning edge.

Case Study: LURA’s Partnership with Lewei Precision for Precision Rocket Engine Parts

LURA, the Leeds University Rocket Association, used Lewei Precision’s 5-axis CNC machining and turn-mill compounding techniques to create intricate engine parts essential for their victory in the National Race to Space Propulsion Competition.

Case Study: Andrea Piccino Collaborates with Lewei Precision to Bring the “Iron Man Suit” to Live

Andrea, a dedicated mechanical engineer from Italy, utilized Lewei Precision 5-axis CNC machining to produce a full-body passive exoskeleton that boosts human strength and minimizes physical strain.

Case Study: Lewei Precision Powers Arco Aria’s Tether Car Success

Thanks to Lewei persicion, Arco successfully modified his tether car’s engine, including turning the crankshaft and designing a new intake system for improved efficiency.

Why Choose Us

Customization

Lewei Precision excels in providing customized injection molding solutions tailored to the specific needs of each industry.

Utilizing state-of-the-art machinery and precision tooling, Lewei Precision ensures that every part is manufactured with tight tolerances and superior quality.

Lewei Precision offers fast lead times and scalable production, making us a reliable partner for projects of any size.

CNC Machining FAQs

What are the typical lead times for injection molding projects at Lewei Precision?

Lead times vary, with prototypes taking 1-3 weeks, low-volume production 3-6 weeks, and high-volume production 4-12 weeks.

How does Lewei Precision ensure the quality of injection molded parts?

We employ strict quality control through DFM reviews, inspections, and advanced tools like CMMs, ensuring precision at every step.

Can Lewei Precision handle both low and high-volume production runs?

Yes, we handle both low-volume (100-10,000 pcs) and high-volume production (10,000+ pcs), adapting to your specific needs.

What types of tooling does the company use for injection molding?

We use soft tooling for prototyping, aluminum tooling for low-volume, and steel tooling for high-volume production.