Injection Mold Tooling Service

Our injection mold tooling service provides high-precision, cost-effective solutions for custom molded parts with quick-turnaround times, making it ideal for both prototyping and production.

- Quick-turn prototypes and production parts in days

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

- Support for both low and high-volume production

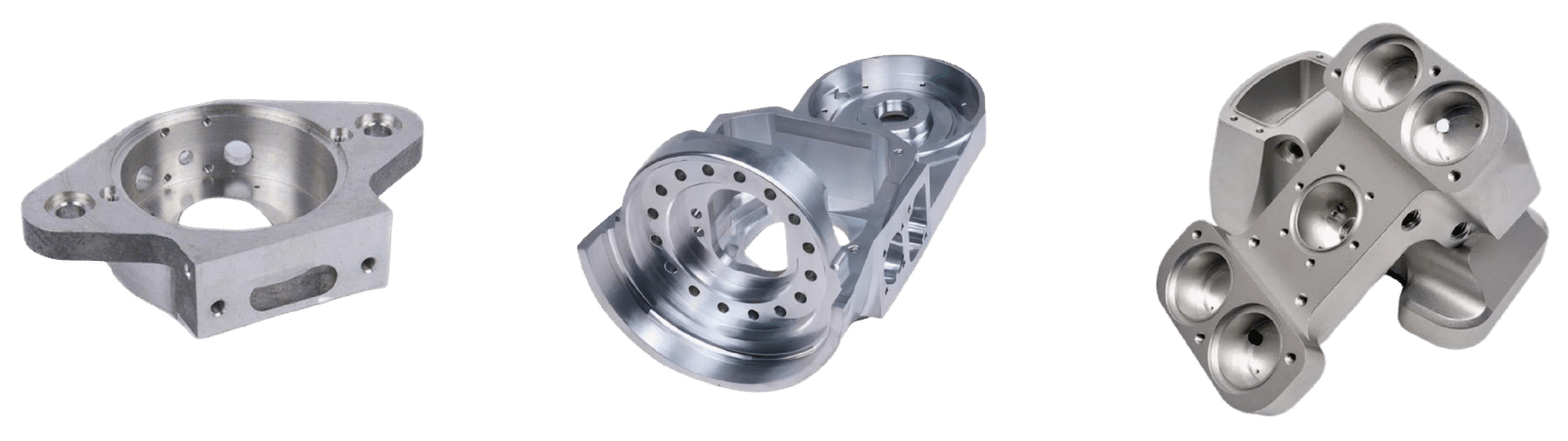

Our ISO-certified CNC machining guarantees high-quality parts with precision at every stage. Each component is crafted to meet exact specifications and perform reliably.

Leveraging our certified domestic facilities and efficient supply chain, we shorten production times, ensuring your injection molded parts are delivered as quickly as possible.

With extensive experience across various molds and products, our team offers expert advice and solutions to help you achieve your business objectives efficiently.

Tooling for Optimal Performance

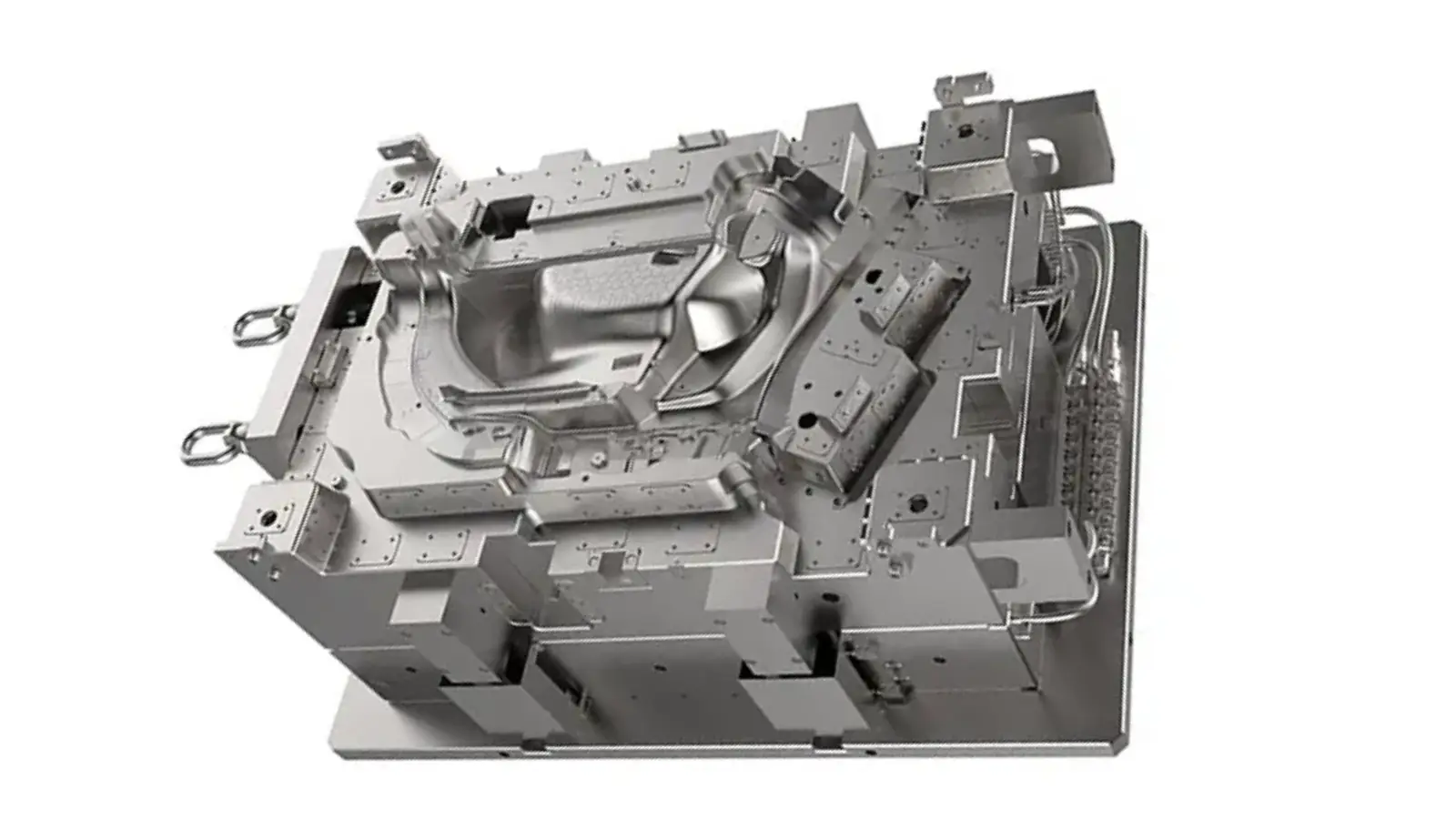

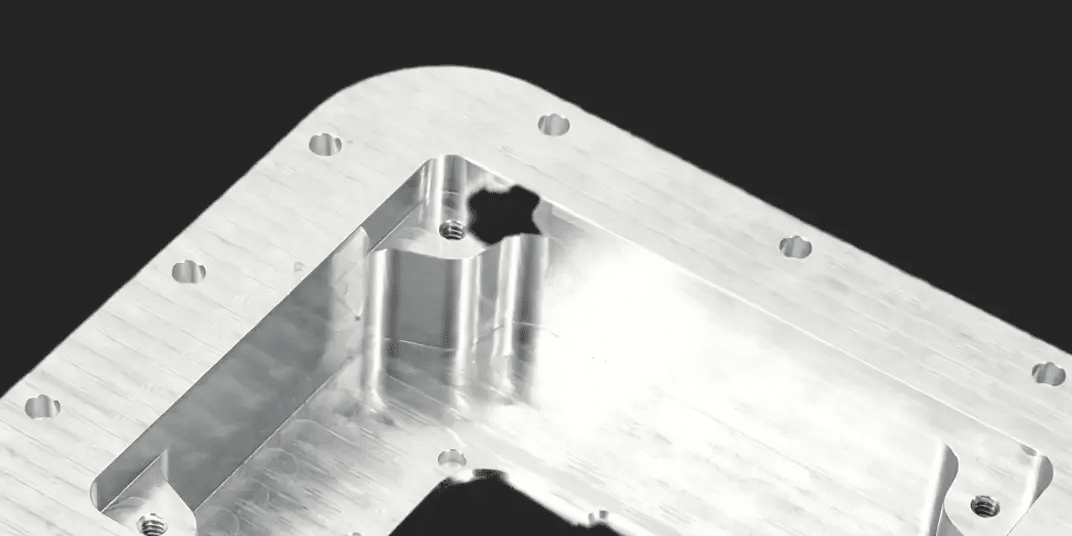

At Lewei Precision, we specialize in high-precision tooling to ensure that every injection molded part fits perfectly and performs flawlessly. Our advanced technology and expert team meticulously craft each mold to meet the tightest tolerances, guaranteeing the highest level of precision and quality for your project.

We use state-of-the-art equipment and rigorous quality control measures to ensure that every mold is built to last and delivers consistent results. With Lewei Precision, you can trust that your parts will meet exact specifications and function reliably in any application.

Mold Tooling Services

Rapid Tooling

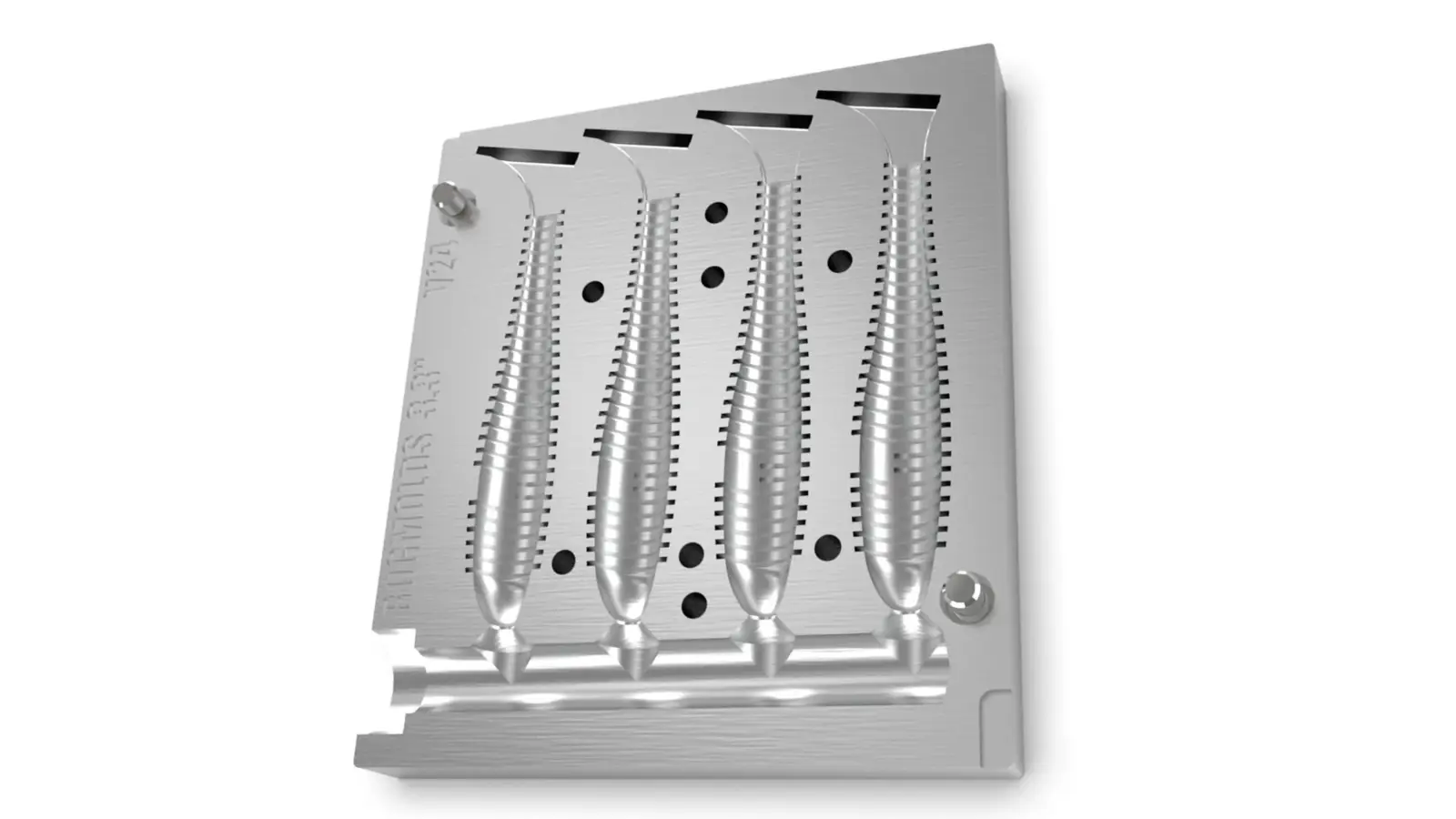

We offer fast and cost-effective prototyping and rapid tooling services to help you validate your designs quickly. Our expert team works with you to provide superior quality prototype tooling, enabling you to produce small batches of plastic molded parts. We utilize affordable aluminum tooling to minimize financial risks, allowing you to perform functional tests and gauge market interest before moving to full-scale production.

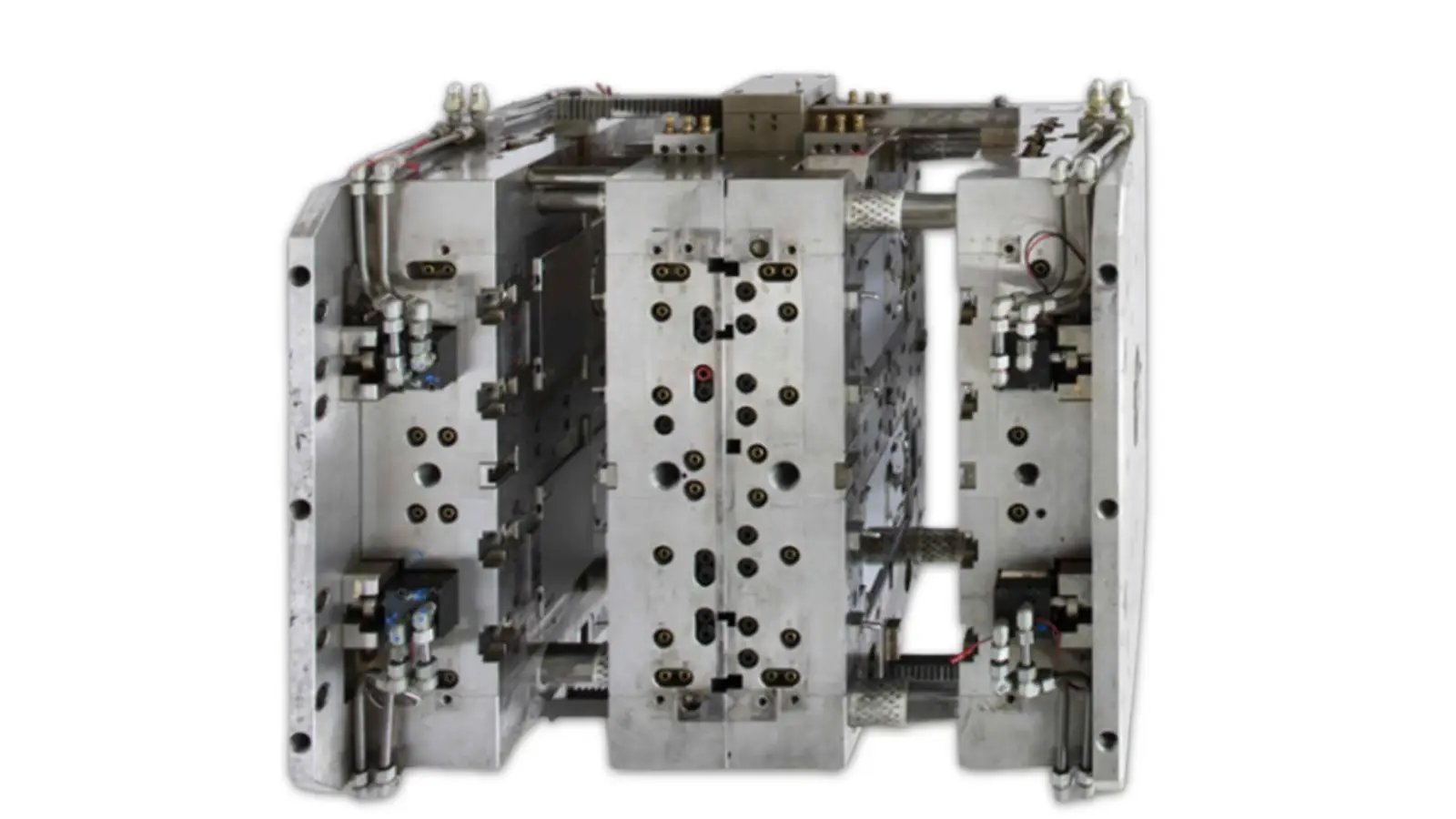

Tooling for High-Volume Runs

Lewei Precision specializes in creating durable, high-quality production molds for high-volume plastic parts manufacturing. Using robust tool steel materials, our production tooling is designed to withstand the demands of producing hundreds of thousands of parts. We tailor materials and construction methods to meet the specific requirements of your project, ensuring efficient and reliable mass production.

Types of Injection Molds

Lewei Precision offers a wide range of injection mold tooling options, tailored to meet your specific needs and applications. From prototype molds to production and export molds, we are your trusted partner in delivering precision solutions for all your molding requirements.

For low-volume production of plastic parts, our single cavity molds provide high-quality, cost-effective tooling. This option gives you more control over the manufacturing process, ensuring consistent, reliable results for small batch production.

Lewei Precision offers innovative stack molds that significantly increase output by utilizing multiple cavities in each parting surface. These molds improve molding efficiency and reduce overall part costs, enabling the creation of multi-component assemblies in a single shot.

Maximize production efficiency with our multi-cavity molds, designed to produce multiple parts per cycle. This tooling solution reduces unit costs while optimizing cycle times, enabling you to achieve higher productivity and greater quantities of parts with each cycle.

For custom molding with two different plastic materials, our 2K injection molds offer a cost-effective and efficient solution. By combining soft and hard plastics into one product, our tooling eliminates assembly steps, saving you time and money while producing high-quality, multi-material products.

Materials for Injection Mold

Tool steel is a commonly used material for injection molding tooling, particularly for high-precision CNC machined molds required in both low and high-volume production. Tool steels provide excellent durability and high tolerance for demanding applications.

Types: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

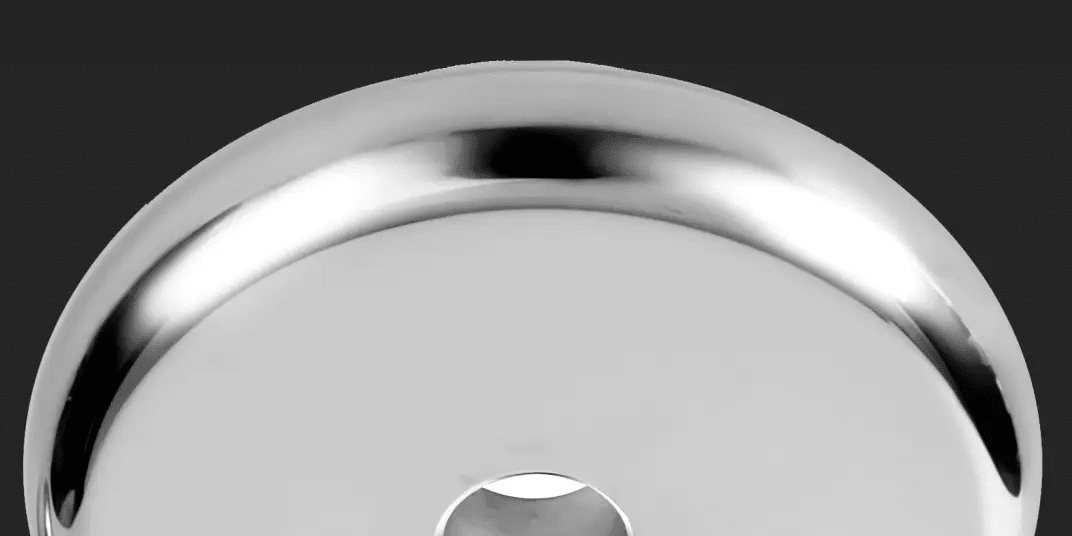

Stainless steel is often used for injection molds in large-scale production due to its high cost and excellent performance. It is known for its corrosion resistance and longevity, making it ideal for high-volume manufacturing where durability and precision are essential.

Types: 420, NAK80, S136, 316L, 316, 301, 303, 304

Copper is another material commonly used for injection molds, particularly when thermal conductivity is a crucial factor. Copper alloys are excellent for applications where fast cooling rates are required, making them ideal for high-production cycles and complex geometries.

Types: C110, C172, C194, C5210

Lewei Precision Injection Molding Capabilities

We are specialized in designing and crafting custom injection molds using high-quality materials. Our efficient processes ensure exceptional consistency and repeatability, delivering fast lead times at competitive pricing.

Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $ | 7-10 days |

Class 104 | Low-volume Production | Under 100,000 cycles | ± 0.02mm | $$$ | 10-15 days |

Class 103 | Low-volume Production | Under 500,000 cycles | ± 0.02mm | $$$$ | 10-15 days |

Class 102 | Medium-volume Production | Medium-volume Production | ± 0.02mm | $$$$$ | 10-15 days |

Class 101 | High-volume Production | Over 1,000,000 cycles | ± 0.02mm | $$$$$$ | 10-18 days |

Advantages

Lewei Precision Plastic Injection Molding Process

Plastic injection molding is a highly efficient and flexible manufacturing process, ideal for producing intricate and high-precision plastic parts.

- Mold Design & Material: Using advanced CAD software, molds are precisely designed to meet the specifications of the product. Molds are typically made from durable steel or lightweight aluminum, selected based on production volume and cooling requirements.

- Consistency: This method offers unmatched consistency in production. Even over large volumes, each part remains identical, reducing the risk of errors and defects in the final product.

- Material Versatility: Precision machining can handle a wide range of materials, from metals to plastics and composites. This flexibility allows manufacturers to choose the ideal material for specific properties like strength, weight, or resistance.

- Complex Geometries: With advanced CNC machines, manufacturers can create complex shapes that would be difficult or impossible to achieve through manual processes. This capability is vital for developing innovative products and components.

- Reduced Waste: Since precision machining is so accurate, it minimizes material wastage. This efficiency not only saves on raw materials but also reduces the overall environmental impact of manufacturing.

- Speed: Modern precision machining techniques are highly automated, leading to faster production times compared to traditional methods. This speed enables quicker turnaround times for projects, keeping pace with market demands.

Applications

Applications of Plastic Injection Molding

Various industries rely on precision CNC machining services to create specialized parts, including:

- Automotive Parts:Plastic injection molding is widely used to produce high-precision automotive components, including dashboards, bumpers, door panels, and interior parts. It provides strong, lightweight, and durable solutions that meet performance standards.

- Medical Devices: Plastic injection molding is used to create enclosures for electronic devices such as smartphones, laptops, and home appliances. The process ensures intricate designs, durability, and the ability to accommodate various electronic components.

- Packaging:Injection molding plays a key role in producing plastic packaging solutions, including bottles, containers, and caps. It offers cost-effective, scalable solutions for both single-use and reusable packaging needs.

- Toys and Games: Plastic injection molding is ideal for creating high-quality, durable toys and games. It enables the production of intricate designs and vibrant colors, ensuring both safety and functionality.

- Household Products:From kitchenware to home décor, injection molding is used to produce a wide range of household items. It offers versatility in design and materials, providing both aesthetic appeal and durability.

CNC Machining FAQs

How do you ensure mold accuracy and consistency during production?

We use advanced CNC machining and precision inspection tools like CMM to maintain tight tolerances and ensure consistency throughout production.

What is the role of cooling channels in injection mold tooling?

Cooling channels regulate the mold temperature, improving cycle times and ensuring uniform part cooling to prevent defects like warping.

Can Lewei Precision create molds for multi-material injection molding (2K molding)?

Yes, we can design molds for 2K molding, allowing the combination of two materials into one part, which improves functionality and reduces assembly steps.

How does Lewei Precision handle complex part geometries in mold design?

We use advanced CAD software and 3D modeling to design molds that accommodate complex geometries, undercuts, and intricate details for precise part production.