Lewei Precision As Machined Services

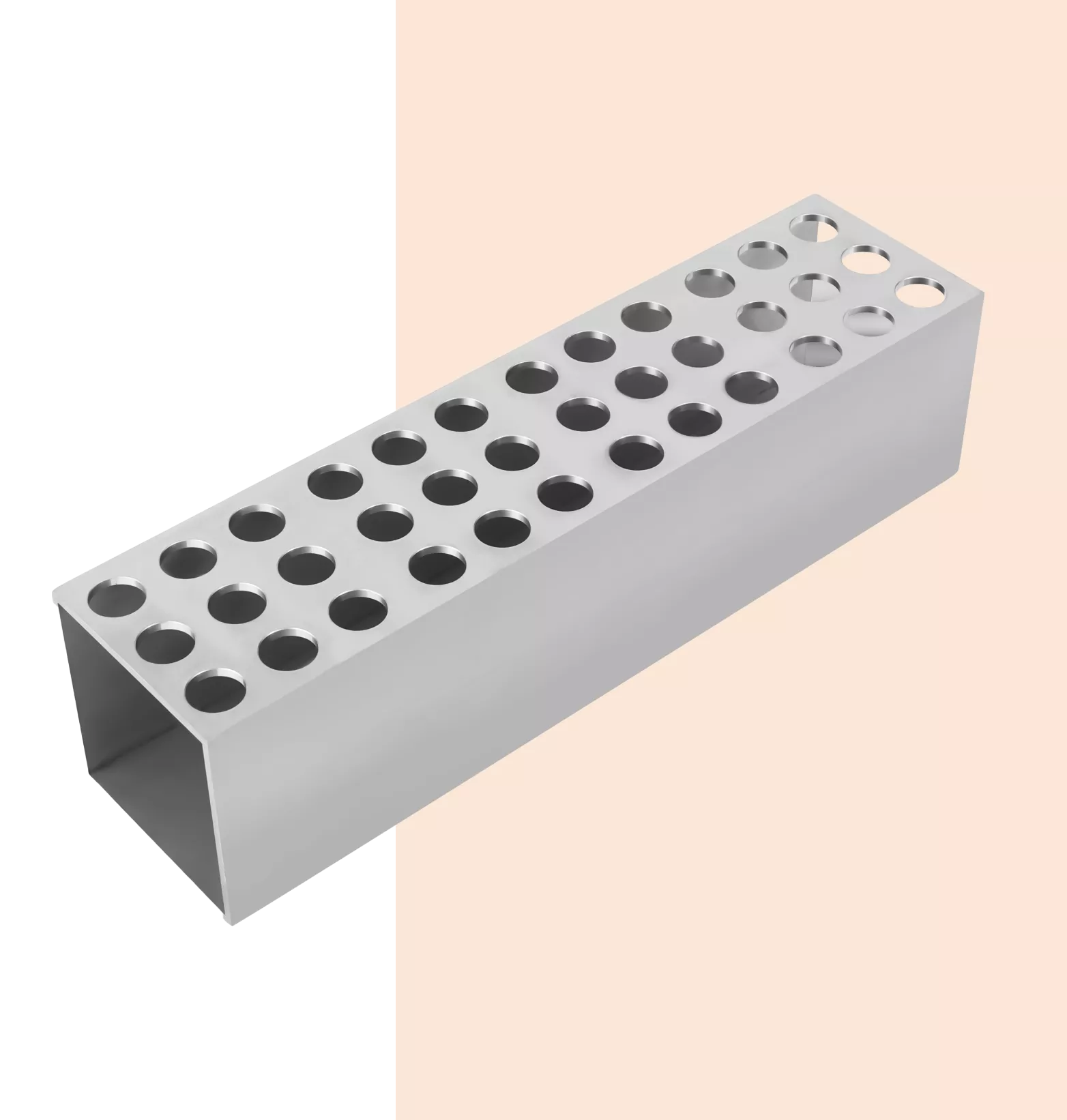

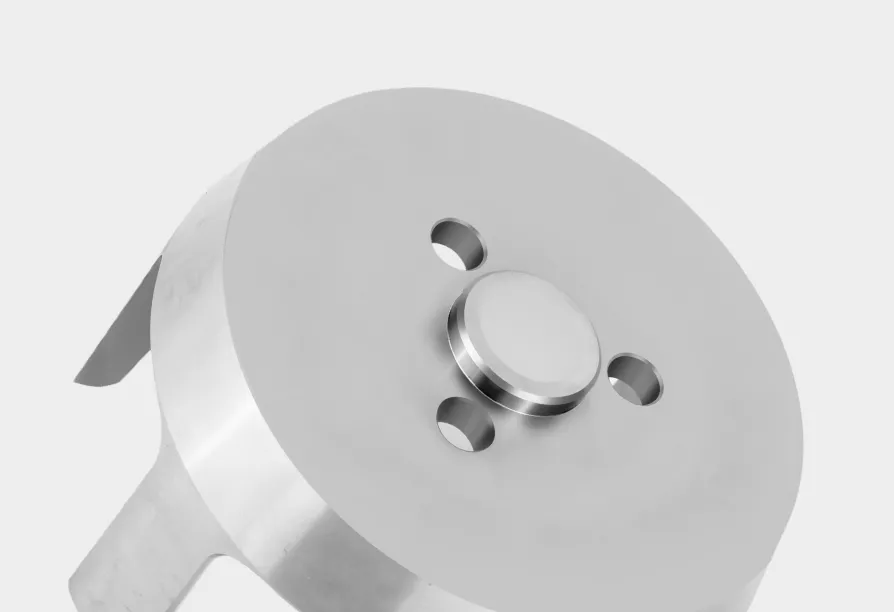

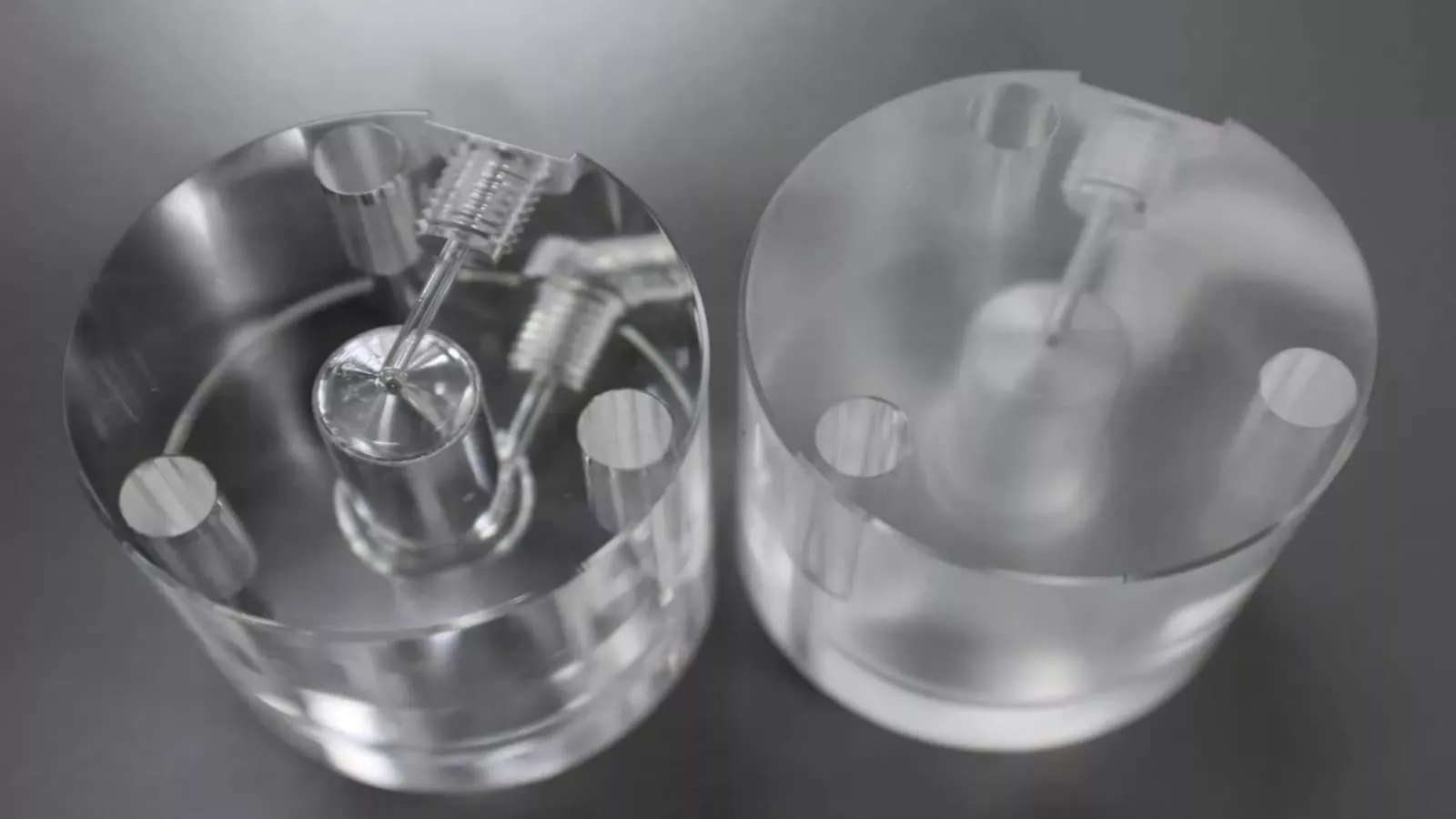

Our quality-focused As Machined services produce parts with surface finish having a surface roughness of Ra 3.2μm and Ra 1.6μm without additional finishing.

As Machined Overview

Parts with as-machined surface finish are characterized by visible tool markings with a surface roughness depending on the machine tool, cutting parameters, tool paths, and the operator’s expertise.

This surface finish is what you get after freshly machining a part without subjecting it to additional processing like honing, grinding, and other surface finishing treatments.

As machined services deliver a machined surface finish, the most convenient option for parts needing tight tolerance and reduced manufacturing cost.

Surface Roughness

Applicable Materials

Cosmetic Availability

Visual Appearance

Ra 1.6μm

Ra 1.6μm

Ra 1.6μm

Cleaning, deburring, and breaking sharp edges only after machining presents a surface without further refinement.

Ra 1.6μm

Ra 1.6μm

Ra 1.6μm

Cleaning, deburring, and breaking sharp edges only after machining presents a surface without further refinement.

Advantages of As Machined Surface Finish

- Faster production time because it does not require extra finishing steps

- It preserves the workpiece’s integrity and retains its natural look

- Extensive machining material supports

- Suitability for parts with strict dimensional tolerances.

- Cost-effectiveness because the surface finish does not require additional processing

Notes

- A finishing cutting pass can be applied to reduce the roughness of a surface down to 0.8 or 0.4 μm.

As Machined Design Considerations

- Simplify the Part Geometry: Avoid complex part design and reduce tight tolerance when feasible to facilitate a smoother machining operation and reduce surface imperfections.

- Optimize Tooling and Toolpaths: Use sharp and high-quality tools and carefully planned tool paths to minimize vibrations and enhance cutting efficiency, which can affect the surface finish.

- Select Machinable Materials: Use CNC machining materials with excellent machinability and favorable surface finish properties.

Surface Finishing Resources

常见问题

如何确保生产过程中模具的准确性和一致性?

我们使用先进的 CNC 加工和精密检测工具(如 CMM)来保持严格的公差,确保整个生产过程的一致性。

冷却通道在注塑模具中的作用是什么?

冷却通道可调节模具温度,缩短循环时间,确保部件冷却均匀,防止出现翘曲等缺陷。

乐为精密可以制造多种材料注塑成型(2K 成型)的模具吗?

是的,我们可以设计 2K 成型模具,将两种材料组合成一个零件,从而提高功能性并减少装配步骤。

乐为精密如何在模具设计中处理复杂的零件几何形状?

我们使用先进的 CAD 软件和三维建模来设计模具,以适应复杂的几何形状、底槽和复杂的细节,从而实现精确的零件生产。