IfIf you’re exploring manufacturing methods for plastic parts, you’ve probably encountered the hot debate: blow molding vs injection molding. Whether you’re making beverage bottles or toy components, you want a straightforward guide to help you pick the right process.

You might be asking yourself: “Which method suits my product best?” or “Where can I get a quick summary without the technical jargon?” The truth is, blow molding and injection molding serve different purposes, sometimes overlapping but each with unique advantages in speed, design flexibility, and material use.

In this article, we’ll break down the basics of both methods, explore industries that rely on them, discuss different injection molding types, and help you decide which is right for your project. No advanced engineering degree needed just clear info from 数控乐为, your manufacturing partner.

Blow Molding vs Injection Molding: The Basics

Blow molding is the go-to method for hollow parts like bottles, while injection molding excels at solid products with complex shapes. Understanding these differences helps you evaluate product durability, cost, and scalability.

Hollow Parts? Blow Molding Shines

Blow molding forms hollow items by inflating heated plastic inside a mold using air pressure. It’s fast, efficient, and perfect for high-volume products such as bottles and containers found in food, beverage, and personal care industries.

Need Precision and Complexity? Injection Molding is King

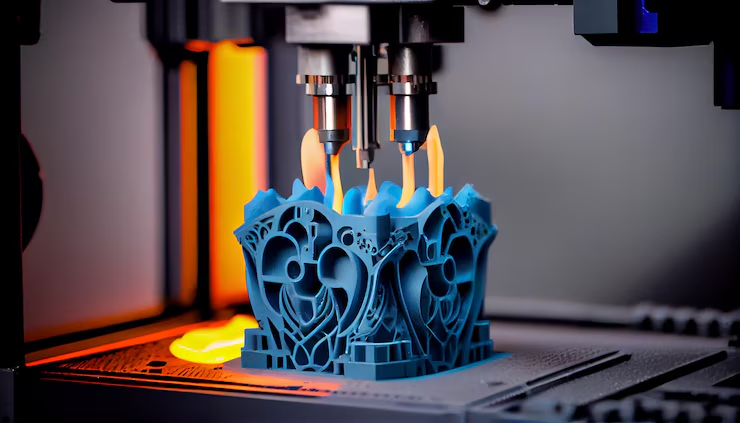

Injection molding forces molten plastic resin into a mold cavity under pressure, capturing detailed designs. From automotive parts to household goods, it reliably produces precise, repeatable solid parts—even in large quantities.

Material Flexibility

While blow molding mostly uses thermoplastics like PET or HDPE, injection molding handles a wider range including thermoplastics, thermosets, composites, and even metals (in specialized cases).

How Blow Molding Works

Blow molding creates hollow plastic parts like soda bottles, shampoo containers, or any empty-shaped packaging.

Process Overview:

- Melting: Plastic is heated until malleable.

- Clamping: Heated plastic (called parison or preform) is clamped inside a mold.

- Inflation: Compressed air inflates the plastic to match the mold shape.

- Cooling: The part solidifies as it cools.

- Ejection: The mold opens, and the finished part is removed.

Common Materials: PET, HDPE, PP.

Advantages:

- Ideal for lightweight hollow containers

- Fast production for high volumes

- Minimal material waste

Industries Using Blow Molding:

- Food & Beverage: Bottles for soda, juice, water

- Household Cleaning: Detergent & spray bottles

- Pharmaceuticals: Medical liquid containers

- Personal Care: Shampoo & lotion bottles

Injection Molding Explained

Injection molding creates solid plastic parts with detailed shapes, from tiny toys to car bumpers.

Process Overview:

- Plastic pellets are melted in a barrel.

- Molten plastic is injected under pressure into a mold cavity.

- The plastic cools and solidifies.

- The mold opens, and the finished piece ejects.

Injection Molding Types:

Industry Uses: Who Chooses What?

| 行业 | Blow Molding Applications | Injection Molding Applications |

|---|---|---|

| 汽车 | Fluid reservoirs (e.g., washer fluid bottles) | Dashboards, bumpers, interior panels |

| Medical & Pharma | Bottles for pills, syrups, solutions | Plastic medical devices requiring tight tolerances |

| Consumer Goods | Shampoo bottles, cosmetic containers | Toys, phone cases, utensils |

| Food & Beverage | Large beverage bottles, milk jugs | Caps, closures, small components |

Key Differences at a Glance

| Factor | Blow Molding | 注塑成型 |

|---|---|---|

| Finished Shape | Hollow (bottles, containers) | Solid, complex geometries |

| Material Use | Thermoplastics like PET, HDPE | Thermoplastics, thermosets, metals |

| Cycle Time | Generally faster for simple shapes | Varies; longer for complex parts |

| Tooling Cost | Lower to moderate | Higher due to precision molds |

| 生产量 | Ideal for high-volume containers | Suited for both high volume and specialized parts |

| Industry Examples | Food, beverage, personal care | Automotive, electronics, toys, medical |

Cost & Scalability Insights

- Tooling & Setup: Blow molding molds shape hollow exteriors, usually less costly for simple shapes. Injection molding requires complex cavity molds, increasing upfront cost but offering lower per-piece cost at scale.

- Material Efficiency: Blow molding uses minimal plastic for thin walls, while injection molding might need thicker sections, increasing material use.

- Scalability: Injection molding scales well for solid parts in very high volumes; blow molding is unbeatable for mass-producing hollow containers.

Final Thoughts

Choosing between blow molding and injection molding depends on your product’s shape, production volume, budget, and material needs. Blow molding is unbeatable for hollow containers; injection molding dominates complex, detailed solid parts. Both will remain manufacturing mainstays in 2025 and beyond.

By understanding your design’s geometry and production goals, you can make an informed decision that minimizes waste, ensures quality, and optimizes costs.

常见问题

Q: Which process has faster cycle times?

A: Blow molding generally has faster cycles for simple hollow shapes. Injection molding times vary with part complexity.

Q: Are tooling costs very different?

A: Yes, injection molding typically involves higher tooling costs due to mold complexity.

Q: Can I switch between processes if my design changes?

A: It’s possible but may require new tooling and a redesign suited to hollow or solid structures.

For expert advice or to explore custom molding solutions, contact 数控乐为—your trusted partner in advanced manufacturing.