What is Precision CNC Machining?

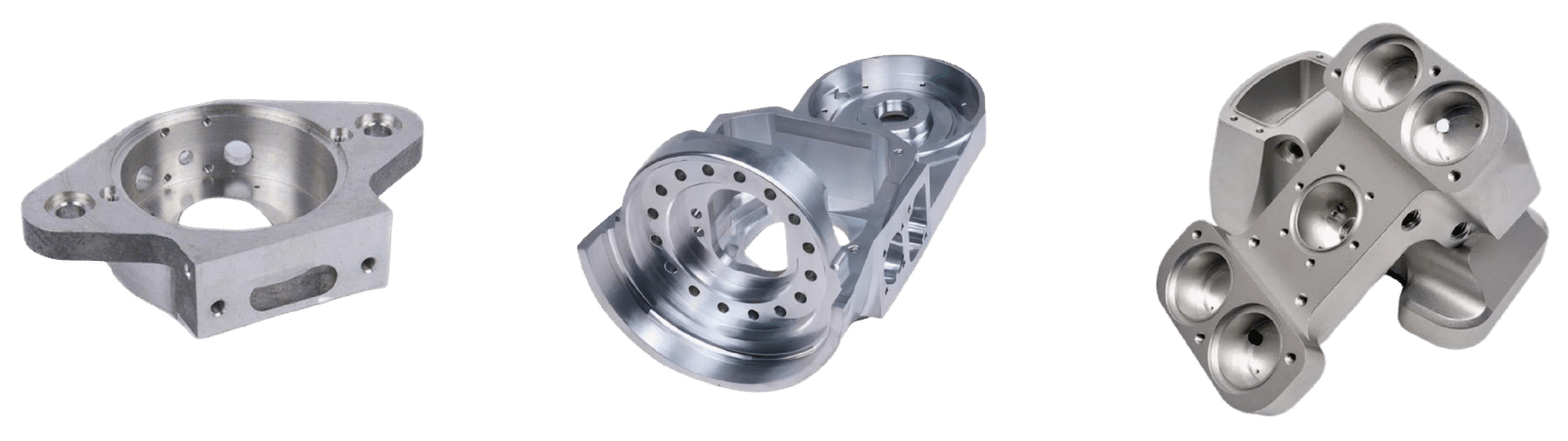

Precision CNC machining uses advanced technology to produce highly accurate parts required in industries such as aerospace, medical devices, and electronics. This process ensures that every component meets exact specifications for size, shape, and function. CNC precision machining is essential for creating detailed and complex designs that standard machining methods cannot achieve, producing high-quality parts like gears, brackets, and enclosures.

Our capabilities enable the production of parts that fit precisely within advanced machinery and devices, guaranteeing reliability and efficiency. Whether for small prototypes or large-scale production, we provide durable, dependable components tailored to meet the unique needs of our clients.

CNC Machining Solutions

Wire EDM Service

Lewei Precision’s wire EDM service, part of our CNC offerings, efficiently produces both simple and complex shapes with exceptional precision. This no-contact method minimizes burrs and is ideal for metals such as steel and titanium. Widely used in industries like aerospace, automotive, and electronics, our wire EDM service ensures tailored solutions that meet your exact specifications.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper

宽容

± 0.0001 inches (0.0025 mm) or better (based on material and thickness)

Maximum Workpiece Size

Length: 16 inches (400 mm)

Width: 12 inches (300 mm)

Height: 8 inches (200 mm)

Cutting Speed

Up to 300 mm2/min (specific to material and thickness)

表面处理

As fine as Ra 0.2 µm

Maximum Cutting Thickness

Up to 12 inches (300 mm) – varies based on material

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

CNC Milling Service

Lewei Precision’s multi-axis milling machines deliver CNC parts with tight tolerances and precise dimensions. Our technology ensures precision tailored to your specific needs, making it ideal for prototypes and new product development. Compatible with a wide range of materials, including metals and composites, our CNC milling services offer high efficiency, with parts ready quickly.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper

宽容

± 0.0001 inches (0.0025 mm) or better (based on material and thickness)

表面处理

As fine as Ra 0.2 µm

Maximum Workpiece Size

X: 40 inches (1016 mm) <br> Y: 20 inches (508 mm) <br> Z: 25 inches (635 mm) or machine-specific

Axis

2-axis, 3-axis, and multi-axis turning capabilities

Bar Feeding Diameter

Up to 3 inches (76 mm) or machine-specific

Mirror EDM Service

Lewei Precision’s Mirror EDM service produces mirror-reflective parts with exceptional precision. Ideal for creating intricate shapes with tight tolerances, it excels with hard materials that are difficult to machine using conventional tools. Serving industries from aerospace to electronics, our Mirror EDM ensures unmatched accuracy, capturing fine contours and complex geometries consistently.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper

宽容

± 0.00005 inches (0.0013 mm) or better (based on material and thickness)

Maximum Workpiece Size

Length: 16 inches (400 mm)

Width: 12 inches (300 mm)

Height: 8 inches (200 mm)

Maximum Cutting Thickness

Up to 10 inches (250 mm) – varies by material

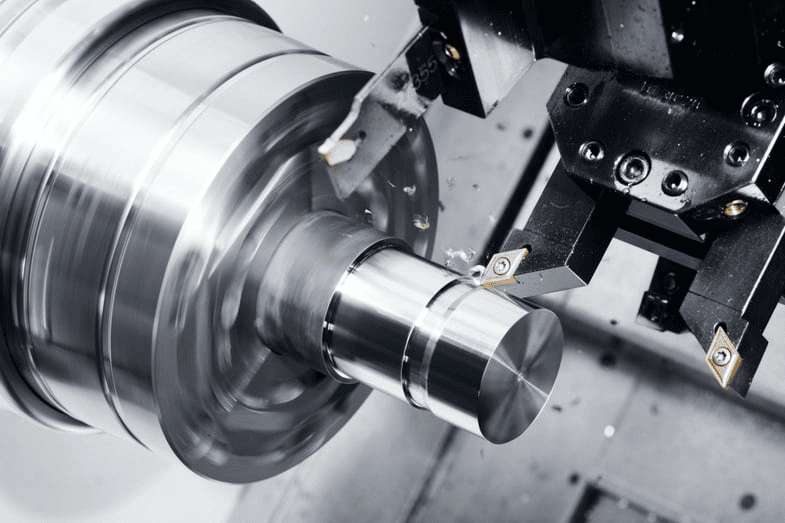

CNC Turning Service

Lewei Precision’s advanced CNC turning services provide exceptional accuracy and repeatability for both machine parts and prototypes. Our diverse range of turning centers caters to a wide variety of applications, ensuring consistent precision across multiple batches. With minimized errors, we offer faster production without compromising quality. Trust our skilled technicians and top-of-the-line CNC machines for outstanding component craftsmanship.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper

宽容

± 0.0005 inches (0.0127 mm) or better (dependent on material and operation)

Maximum Workpiece Size

60 inches (1524 mm) or machine-specific capability

Bar Feeding Diameter

Up to 3 inches (76 mm) or machine-specific

Maximum Workpiece Diameter

0 inches (508 mm) or machine-specific capability

Axis

2-axis, 3-axis, and multi-axis turning capabilities

Grinding Service

Lewei Precision’s advanced manufacturing facility is equipped with high-precision grinding machines, ideal for producing metal parts with tight tolerances. Our versatile grinding capabilities cater to both small components and complex geometries. With precision wheels ensuring controlled material removal, we provide polished finishes that minimize costs, wear, and errors. Trust our skilled team to recommend the perfect grinding solution for your project.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Aluminum, Tool Steel, Copper, Ceramics, Carbides

Grinding Methods

Surface Grinding, Cylindrical Grinding, Centerless Grinding, Internal Grinding

Cutting Speed

Up to 300 mm2/min (specific to material and thickness)

表面处理

Achievable down to Ra 0.1 µm or better (dependent on material and grinding method)

Maximum Workpiece Size

Length: 24 inches (600 mm) <br> Width: 10 inches (250 mm) <br> Diameter: 8 inches (200 mm) for cylindrical grinding

表面处理

Achievable down to Ra 0.1 µm or better (dependent on material and grinding method)

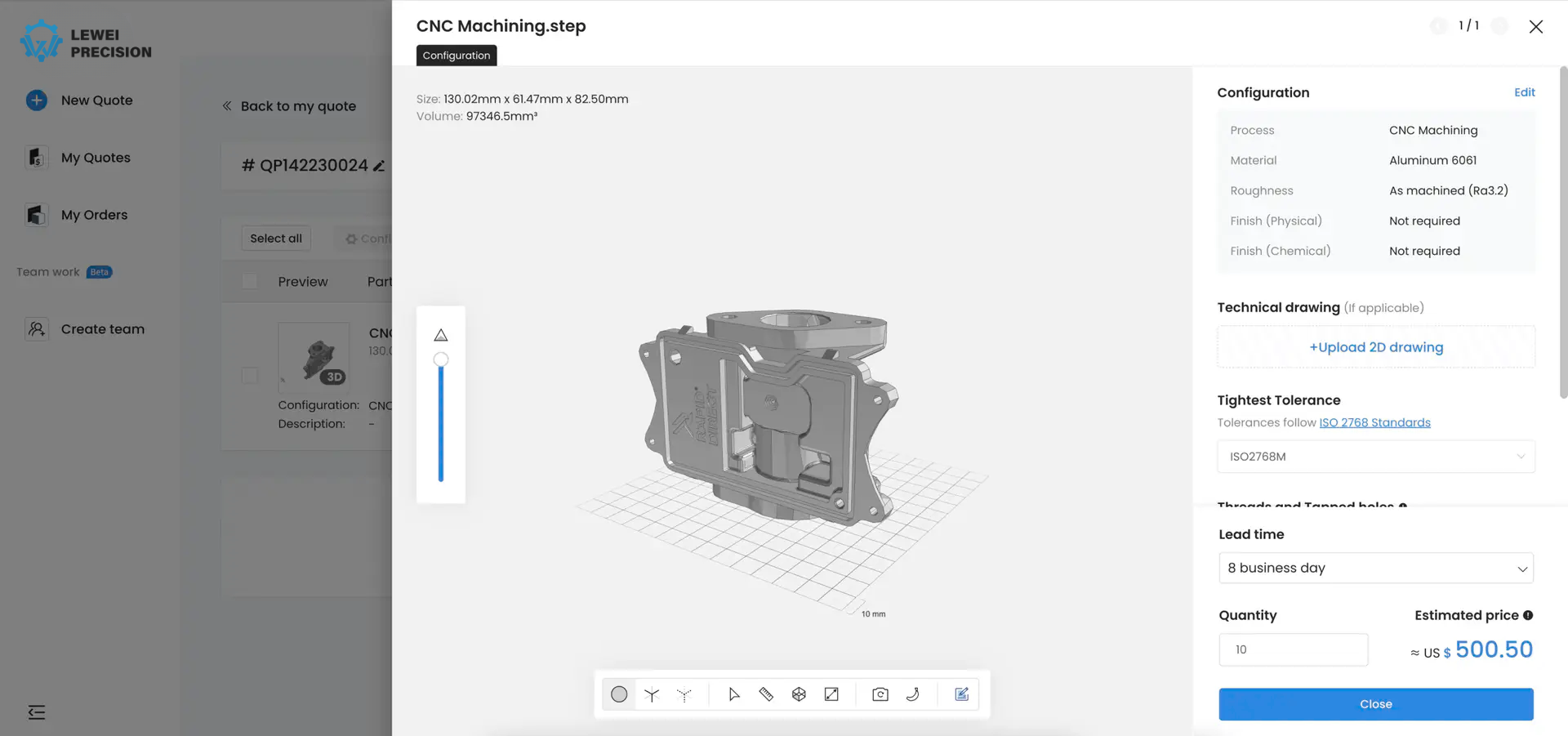

CNC Machining Solutions

快速原型制作

Harness our advanced manufacturing capabilities for fast, high-quality prototype delivery. With cutting-edge technology, we ensure quick and accurate production, speeding up your journey from testing to market readiness.

Low and High-Volume Production

Lewei Precision is fully equipped to handle large-scale production orders, ensuring the efficient production of high volumes of CNC precision machined parts without sacrificing quality or accuracy.

Capacity: 1000+

准备时间: 15 business days

Typical Tolerance (mm) | Best Possible Tolerance (mm) | Notes

| Feature | 说明 |

|---|---|

| 一般公差 | Metals: ISO 2768-m Plastics: ISO 2768-c |

| 精密公差 | Tolerances tighter than ±0.001 inches, as per drawing & GD&T |

| Min Wall Thickness | 0.5 毫米 |

| Min End Mill Size | 0.5 毫米 |

| Min Drill Size | 1 毫米 |

| 最大部件尺寸 | CNC Milling: 4000 × 1500 × 600 mm CNC Turning: 200 × 500 mm |

| 最小部件尺寸 | CNC Milling: 5 × 5 × 5 mm CNC Turning: 2 × 2 mm |

| 生产量 | Prototyping: 1–100 pcs Low Volume: 101–10,000 pcs High Volume: Above 10,001 pcs |

| 准备时间 | 5 business days (most projects) As fast as 1 day (simple parts) |

成功案例

乐威精密 x 斯图加特 Rennteam:赛车工程的创新合作

乐为精密自豪地为斯图加特 Rennteam 车队提供支持,生产 2 个主杆部件和 80 多个铝制镶件。我们的精密工程技术确保这些部件能够征服大学生方程式赛车比赛,为车队带来制胜优势。

案例研究:LURA 与乐为精密合作生产精密火箭发动机部件

利兹大学火箭协会(LURA)利用乐为精密的五轴数控加工和车铣复合加工技术,制造出了复杂的发动机部件,这对他们在全国太空推进竞赛中取得胜利至关重要。

案例研究:Andrea Piccino 与 Lewei Precision 合作,将 "钢铁侠战衣 "带入生活

来自意大利的专职机械工程师安德烈亚利用乐为精密的五轴数控加工技术,制造出了一种全身被动式外骨骼,这种外骨骼可以增强人体力量,最大限度地减轻身体负担。

材料与 表面处理

优势

Applications of Precision Machining

Precision CNC machining services are essential in various industries for creating specialized parts, including:

- Engine Components: Crucial for automotive and aerospace engines, components like pistons and crankshafts require exact dimensions for optimal performance and durability.

- Medical Implants:Used to manufacture surgical implants, including hip and knee replacements, where precise tolerances and smooth finishes are necessary for compatibility with human tissue.

- Aerospace Fasteners:Involves the production of high-strength bolts and screws, designed to withstand extreme conditions in aerospace applications while maintaining reliability.

- 复杂几何: 有了先进的数控机床,制造商就能制造出复杂的形状,而这些形状是手工工艺难以实现或无法实现的。这种能力对于开发创新产品和部件至关重要。

- Tool and Die Making: Focuses on creating molds and dies essential for mass production, ensuring consistency and high-quality parts in manufacturing processes across industries.

应用

Advantages of Precision Machining

Precision machining offers numerous advantages by producing parts with exceptional accuracy and efficiency.

- 高精度: Precision machining tools can produce parts with extremely tight tolerances, ensuring that each component meets exact specifications. This is essential for applications that require intricate details, such as in aerospace and medical devices.

- 一致性: This method guarantees unmatched consistency throughout production, with each part remaining identical even in large volumes. This minimizes the risk of errors and defects in the final product.

- 材料多样性:Precision machining is compatible with a wide variety of materials, from metals to plastics and composites. This versatility enables manufacturers to select the best material for specific attributes like strength, weight, and resistance.

- 复杂几何:Advanced CNC machines allow the creation of complex shapes that would be challenging or impossible with manual processes. This capability is crucial for developing innovative products and intricate components.

- 减少浪费: Due to its accuracy, precision machining minimizes material wastage, saving raw materials and reducing the environmental impact of manufacturing.

数控加工常见问题

What are the applications of CNC machining?

CNC machining has a wide range of applications across industries.

- In the automotive and aerospace sectors, it is used to fabricate precise engine components, structural parts, and other intricate elements.

- The medical industry leverages CNC for manufacturing devices, implants, and surgical instruments.

- CNC is also crucial in electronics, enabling the production of electronic housings, circuit boards, and connectors.

- Machine tool makers rely on CNC to create complex molds, dies, and machine components. Additionally,

- CNC is valuable for general custom part production, prototyping, woodworking, and more, allowing for consistent quality and high precision.

What are the advantages and disadvantages of CNC machining?

Advantages of CNC Machining

Precision and Repeatability: CNC machining ensures high precision and consistent replication of parts, crucial for complex designs with tight tolerances.

Reduced Human Error: The automated nature of CNC machining minimizes human error, enhancing the overall quality of production.

Efficiency and Speed: Automation allows for faster production cycles, enabling quicker turnaround times than manual processes.

Material Flexibility: CNC machines can work with a diverse range of materials, including metals, plastics, and composites, offering versatility across various applications.

Software Integration: Advanced CNC software supports quick design changes and updates, facilitating prototyping and easy customization.

Cost-Effective for Large Runs: While setup costs are higher, per-unit costs decrease significantly with larger production volumes, making it cost-effective for mass production.

Disadvantages of CNC Machining

High Initial Costs: CNC machinery and its maintenance represent significant investments, making initial setup expensive, especially for small-scale operations.

Skill Requirements: Operating CNC machines requires highly skilled personnel, which can increase training costs and limit accessibility.

Less Cost-Effective for Small Runs: Due to setup and programming time, CNC machining may not be economical for producing small quantities of parts.

Material Waste: CNC machining often involves subtractive processes, leading to more material waste compared to additive manufacturing.

Limited to Material Hardness: Extremely hard materials can wear out CNC tools quickly, potentially increasing operational costs and downtime.

Who is the father of CNC machining?

John T. Parsons is often credited as the father of CNC machining. In the late 1940s, Parsons developed the first numerical control techniques and applied them to the production of helicopter rotor blades. Working alongside engineer Frank L. Stulen, Parsons conceptualized the method of using punched tape to guide machine tools. This innovation laid the groundwork for the development of CNC (Computer Numerical Control) technology. Their pioneering work eventually led to the creation of the first CNC machines in the 1950s, which revolutionized manufacturing by improving the precision, efficiency, and repeatability of machining processes.

What is the G and M code in CNC machines?

G and M codes are the programming languages used in CNC machining to control CNC machine tools. G-codes are primarily used for specifying the movements of the machine, such as linear interpolation, circular movements, and other specific functions related to the actual path of the tool. M-codes, on the other hand, handle machine functions that are not directly related to the path of the tool, such as turning the machine on or off, starting or stopping the spindle, and controlling coolant. Together, G and M codes provide a comprehensive set of instructions that CNC machines follow to produce parts accurately and efficiently.

What is machining center and how does it work?

A machining center is a highly advanced CNC machine designed to handle a variety of machining tasks including milling, drilling, and tapping, all within a single setup. This integration enhances efficiency and accuracy by reducing the need to transfer parts between different machines. Machining centers are equipped with a tool turret or magazine that holds multiple tool options, enabling automatic tool changing under CNC control. This capability allows for switching between operations, optimizing production flow. Typically, machining centers are used for complex parts that require precision machining from multiple angles, making them indispensable in modern manufacturing environments.