Custom Online Laser Cutting Services

Get precise laser-cut parts for both rapid prototyping and production needs. Receive a free laser cutting quote with DFM review within one day. Lead times as fast as 3-5 days.

- International prototype pricing includes tariffs

- Quick-turn prototypes and production parts in days

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

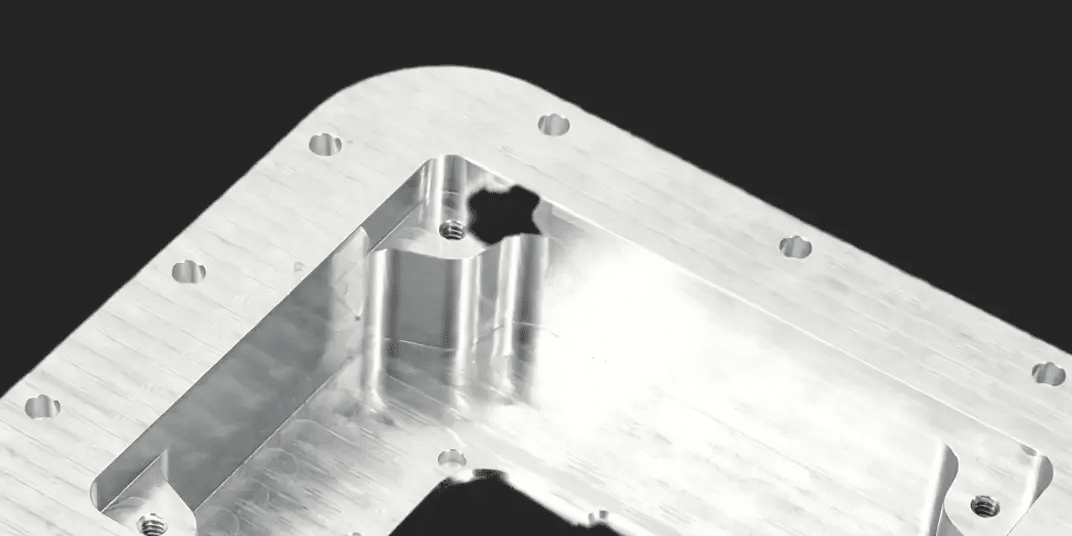

Our state-of-the-art laser cutting machines provide precision in every project. With strict quality control, we ensure that your custom metal parts meet exact specifications, delivering flawless results with every order.

Experience industry-leading speed in project delivery. Our efficient online platform and streamlined production processes reduce wait times, ensuring you receive laser-cut parts quickly and stay ahead in your market.

Our engineering team turns design challenges into practical solutions. We offer hands-on support, ensuring your custom laser cutting projects receive expert technical advice and design optimization for exceptional results.

What is Laser Cutting?

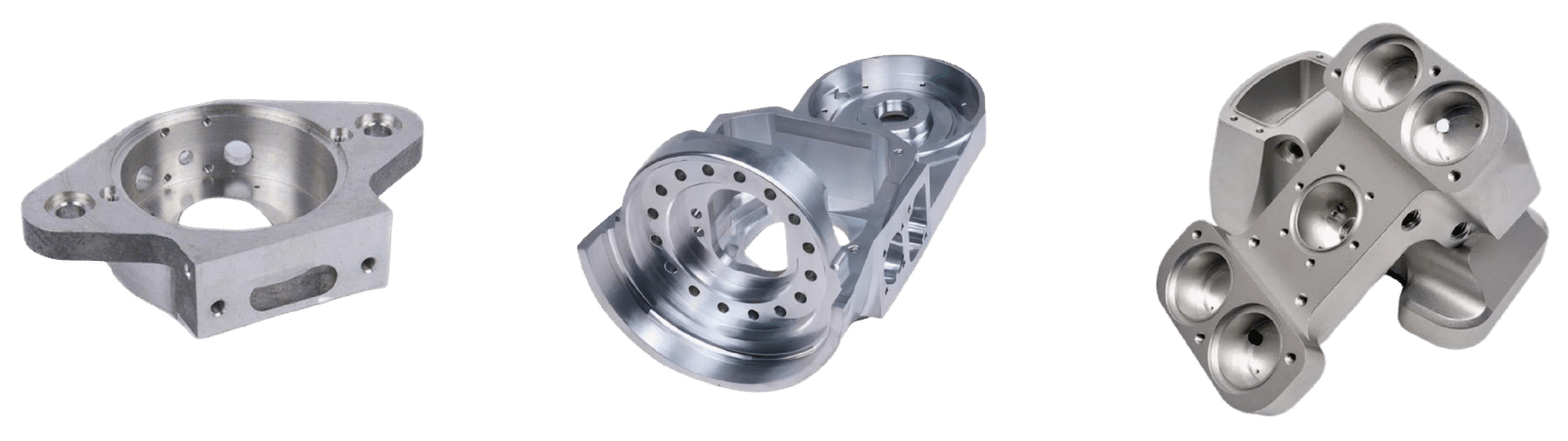

Laser cutting is a precise and efficient manufacturing process that uses a high-powered laser beam to cut materials into custom shapes and designs. This technology excels in creating intricate parts and components with exceptional accuracy and smooth, clean finishes. At Lewei Precision, we offer custom online laser cutting services for a wide variety of materials, including metals, plastics, and even woods, ensuring flexibility for all your project needs.

To streamline your process, Lewei Precision provides an instant quoting system that supports multiple 3D CAD file formats. Simply upload your design to receive a real-time quote, allowing you to move seamlessly from design to production and optimize both time and cost. Our comprehensive online sheet metal laser cutting service combines speed, precision, and accessibility, ensuring that your manufacturing needs are met efficiently.

Types of Laser Cutters at Lewei Precision

Fiber laser cutters at Lewei Precision deliver exceptional precision with minimal setup time, making them ideal for cutting reflective metals. They offer high energy efficiency and fast cutting speeds, making them perfect for both high-volume and custom metal laser cutting projects.

At Lewei Precision, our CO2 laser cutters excel at processing a variety of materials, including metals, plastics, and woods. Utilizing a fine laser beam, CO2 technology ensures clean cuts and intricate detailing, significantly enhancing the quality of your laser-cut parts.

Nd:YAG laser cutters are known for their high power and ability to cut through thick and tough materials. At Lewei Precision, we use Nd:YAG lasers for tasks requiring extreme precision and deep cutting, making them ideal for complex industrial and design challenges.

Laser Cutting Materials

Metals like aluminum, stainless steel, and brass are prized for their durability, strength, and superior corrosion resistance. These qualities make them perfect for both structural applications and intricate aesthetic components.

Plastics such as acrylic and polycarbonate are valued for their light weight, impact resistance, and transparency. These materials provide excellent versatility, making them suitable for a variety of applications, from industrial parts to aesthetically pleasing decorative items.

Wood types like pine, oak, and maple are selected for their natural grain patterns, ease of workability, and strength. Each variety offers a distinct aesthetic, suitable for both structural uses and detailed decorative projects.

Lewei Precision Laser Cutting Capabilities

Our custom laser cutting services adhere to international industry standards and current market trends, ensuring the delivery of high-quality laser-cut parts to our customers.

规格 | 说明 |

最大部件尺寸 | 10 mm (0.40 in.) |

最小部件尺寸 | 2X material thickness with a minimum of 1 mm (0.04 in.) |

Distance Dimensions | Our laser cutting standards depend on ISO 2768-c. Typical size: +/- 0.2 mm (0.008 in.) for length, width, diameter, and location |

Maximum Material Thickness: | Carbon Steel < 25 mm (0.98 in.), Stainless Steel < 15 mm (0.59 in.), Aluminum < 15 mm (0.59 in.), Copper < 12.7 mm (0.5 in.), |

Kerf (Slit Size) | About 0.5 mm (0.02 in.) |

Edge Condition | Laser cut edges have matte and vertical lines |

Laser Sources | CO2 and fiber lasers. Up to 10 kW |

Repeatability | +/- 0.05 mm (0.002 in.) |

Positioning Accuracy: | +/- 0.10 mm (0.004 in.) |

交货时间: | 5-7 days |

Laser Cutting Shop

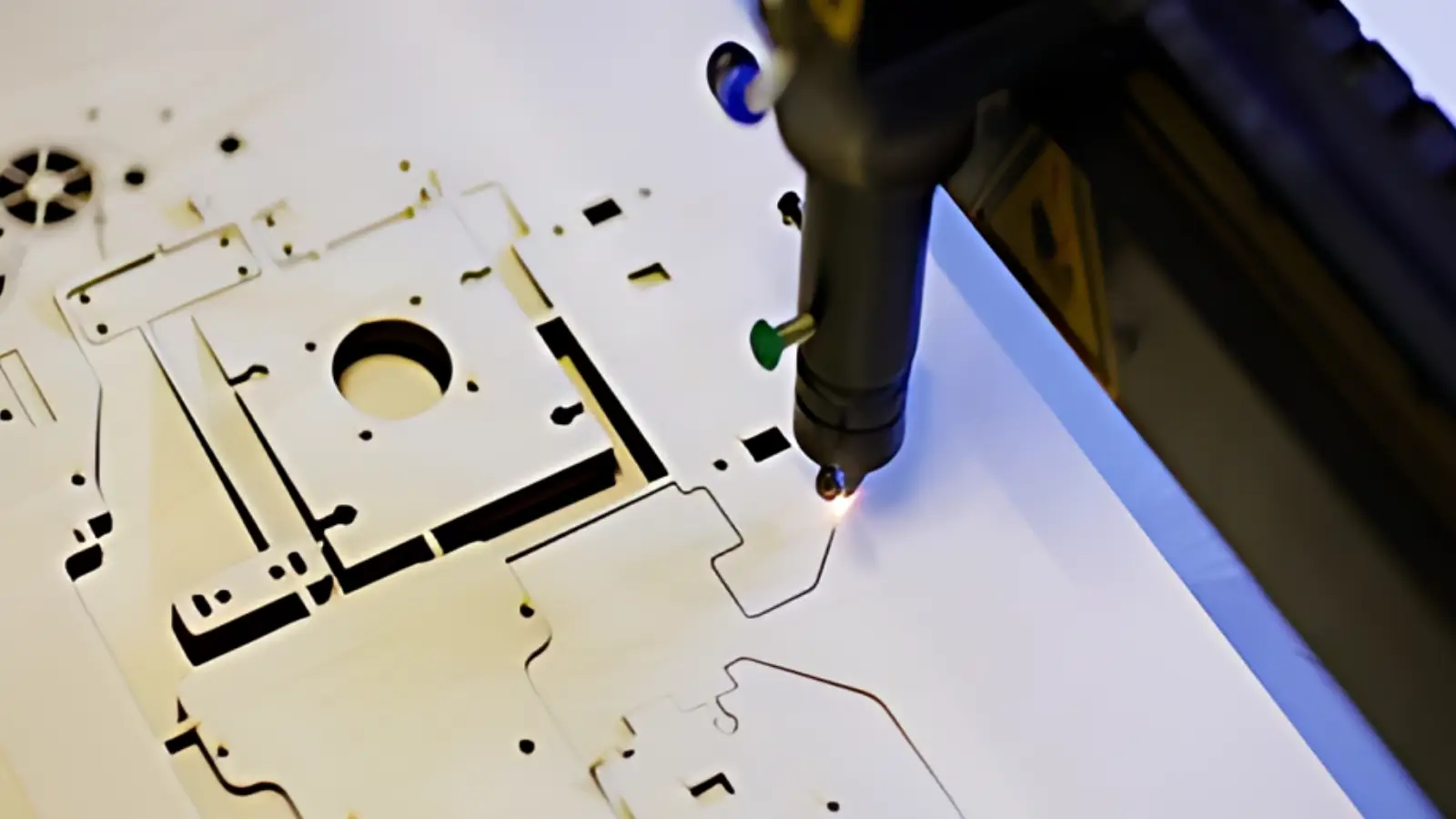

Experience the precision of Lewei Precision’s laser cutting shop, where cutting-edge technology and expert craftsmanship converge. Our shop is equipped with seven advanced laser cutters, each with a capacity of 3000*1500, capable of cutting up to 30mm thick plates with an accuracy of ±0.01mm. This allows us to handle a wide range of materials, from metals to plastics and woods, ensuring high-quality results for every project.

Take a closer look at our operations through our video tour, and see how our laser cutting services deliver both precision and efficiency for each custom project. Watch as we demonstrate our commitment to excellence, bringing your ideas to life with superior craftsmanship.

优势

Advantages of Laser Cutting

Laser cutting technology offers several significant advantages in manufacturing across various industries:

- Precision and Accuracy: Delivers exceptional cutting precision and consistency, ideal for intricate designs and complex patterns. This precision minimizes waste and improves efficiency during production.

- Versatility: Capable of cutting a wide range of materials, including metals, plastics, and woods, laser cutting adapts easily to different industry requirements. It handles diverse material thicknesses and complexities without needing tool changes.

- 速度 Known for its speed, laser cutting reduces production times, making it perfect for both large-scale manufacturing runs and rapid prototyping, speeding up project completion.

- Clean Cuts and Smooth Finish:Produces clean, sealed edges that often require little to no post-processing, saving time and enhancing the aesthetic quality of the final product.

- Reduced Contamination: As a non-contact process, laser cutting minimizes the risk of material contamination, crucial for industries such as electronics or medical devices, where purity is vital.

- Energy Efficiency:Modern laser cutting machines are designed for energy efficiency, reducing operational costs and supporting sustainable manufacturing practices..

应用

Applications of Laser Cutting

Laser cutting technology is widely utilized to fabricate a diverse range of parts, each benefiting from the precision and flexibility of this method:

- Structural Components: Critical for machinery and construction, laser cutting ensures the precision required for structural elements like beams, frames, and supports, guaranteeing a perfect fit in complex structures.

- 装饰元素 Ideal for creating intricate designs such as metal panels and detailed artwork, laser cutting excels in producing decorative pieces with fine, precise cuts. This is commonly used in architecture, interior design, and art installations.

- Functional Parts: Essential in manufacturing components like gears, brackets, and enclosures, laser cutting’s precision ensures these parts work seamlessly within mechanical systems, making it a top choice for automotive and machinery industries.

- 原型: Laser cutting is frequently used by designers and engineers to quickly produce prototypes, allowing for rapid iterations and refinements. This accelerates product development by enabling precise and swift modifications.

- Electronic Components: Laser cutting is critical in the production of delicate electronic parts, such as circuit boards and insulating layers. The ability to cut intricate shapes without damaging sensitive materials is vital for the miniaturization and functionality of electronics.

数控加工常见问题

How accurate are Lewei Precision’s laser cuts?

Our laser cutting service ensures precision with tolerances as tight as ±0.01mm, guaranteeing high-quality, accurate parts for both prototypes and production runs.

What is the maximum thickness Lewei can cut?

Our standard lead time for laser cutting is 5-7 days. However, we offer expedited services for quicker delivery, depending on the complexity and size of your project.

How fast can I receive my laser-cut parts?

We can cut materials up to 30mm thick, depending on the material type. For example, carbon steel can be cut up to 25mm, while aluminum and stainless steel can be cut up to 15mm.

Do you offer custom finishes for laser-cut parts?

Our laser cutting service ensures precision with tolerances as tight as ±0.01mm, guaranteeing high-quality, accurate parts for both prototypes and production runs.