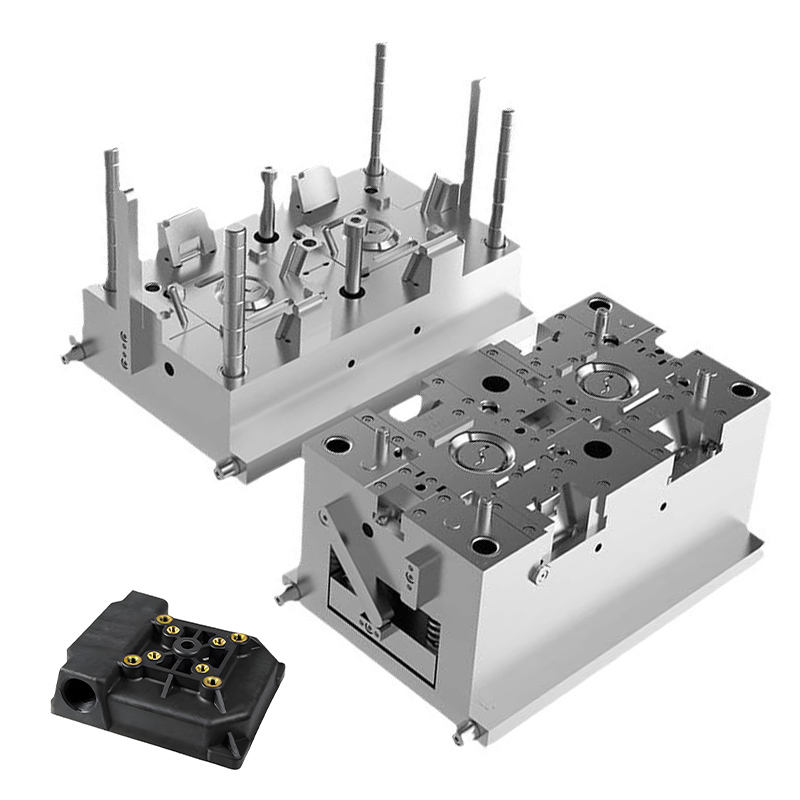

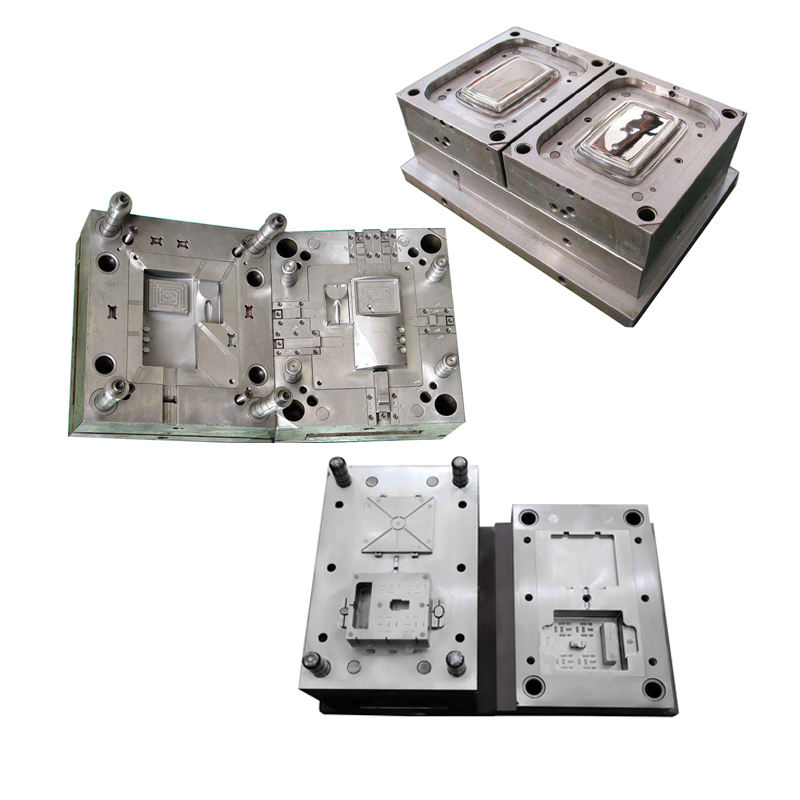

Insert Molding Service

We specialize in insert molding, integrating metal inserts into molded plastics for robust and durable parts suitable for various industries.

- International prototype pricing includes tariffs

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

- Quick-turn prototypes and production parts in days

我们通过 ISO 认证的 CNC 加工可确保精度和质量。每一个零件都经过先进的质量控制,完美匹配,性能无懈可击。

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your overmolded parts as fast as possible.

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

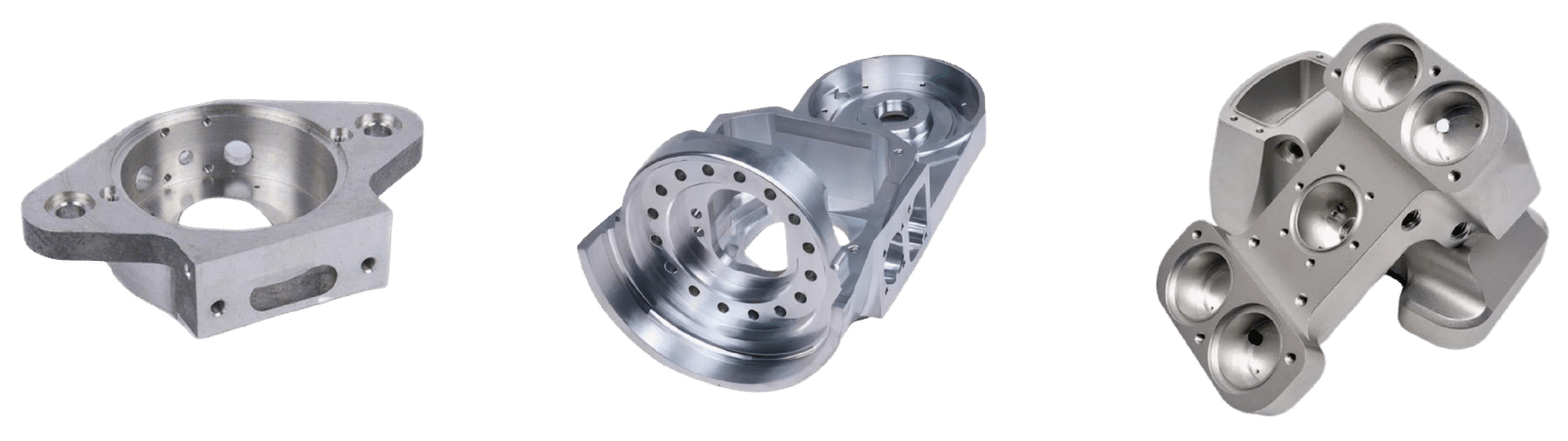

CNC Machining Solutions

Insert molding is an injection molding technique that involves injecting a plastic material around a plastic or metal insert (but can also include ceramic or other materials) placed in a mold cavity. The insert is pre-placed in the mold cavity, after which the plastic is injected. These inserts, including threaded metal inserts for enhanced durability, provide specific mechanical or electrical properties to the final product. For example, metal inserts such as aluminum or stainless steel add tensile strength and conductivity, making insert injection molding ideal for highly durable and functional parts. On cooling, this forms a solid part that is strong and durable. Lewei plastic insert molding services allow you to make a strong and permanent bond between the insert and molded plastic.

CNC Machining Solutions

Lewei Prototyping

Leverage our robust manufacturing capabilities for swift, high-quality prototype delivery. Using the latest technology, we ensure Lewei, accurate production, expediting your path from testing to market.

Capability: 20-500

准备时间: 10 business days

Low and High-Volume Production

Lewei Precision is equipped to handle large-scale production orders. This means they can efficiently produce large quantities of CNC precision machining parts without compromising quality or accuracy.

Capacity: 1000+

交货时间: 15 business days

Materials for Insert Molding

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

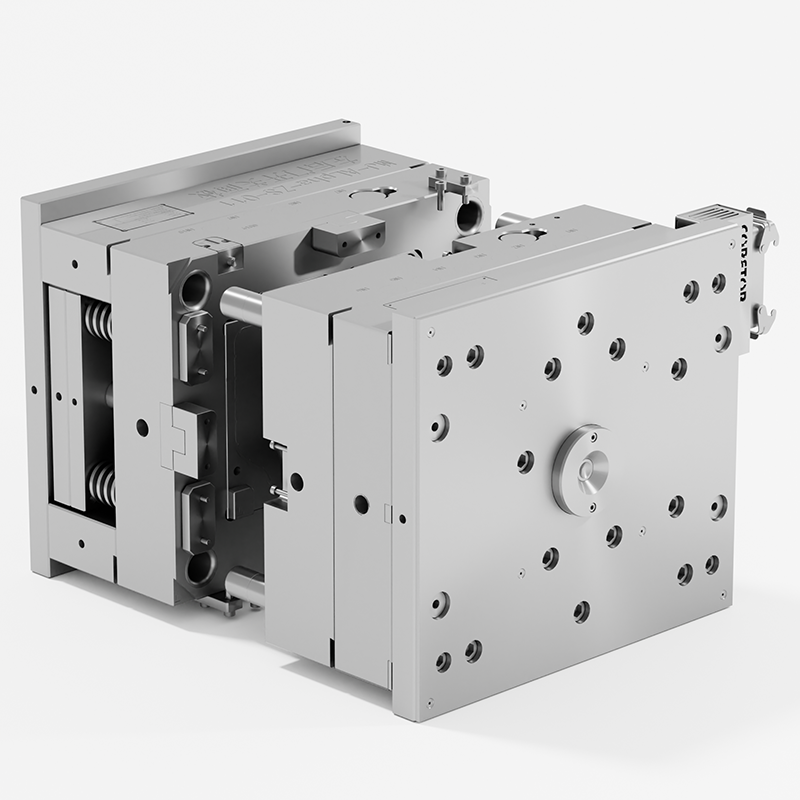

Overmolding Capabilities

Lewei Precision’s wire EDM, part of our CNC services, efficiently crafts both simple and intricate shapes. Ideal for parts requiring high precision, this no-contact method produces minimal burrs and excels with metals like steel and titanium. Favored in aerospace, automotive, and electronics for their accuracy, we ensure tailored, precise solutions regardless of your needs.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper

宽容

± 0.0001 inches (0.0025 mm) or better (based on material and thickness)

Maximum Workpiece Size

Length: 16 inches (400 mm)

Width: 12 inches (300 mm)

Height: 8 inches (200 mm)

Cutting Speed

Up to 300 mm2/min (specific to material and thickness)

表面处理

As fine as Ra 0.2 µm

Maximum Cutting Thickness

Up to 12 inches (300 mm) – varies based on material

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

优势

Advantages of Precision Machining

精密加工能生产出精度极高的零件,因而具有显著的优势。

- 高精度: 精密加工工具可以生产公差极小的零件,确保每件零件都符合精确的规格要求。这对于航空航天和医疗设备等需要复杂细节的应用来说至关重要。

- 一致性: 这种方法提供了无与伦比的生产一致性。即使是大批量生产,每个部件也保持一致,从而降低了最终产品出现错误和缺陷的风险。

- 材料多样性: 精密加工可以处理从金属到塑料和复合材料等各种材料。这种灵活性使制造商能够根据强度、重量或阻力等特定性能选择理想的材料。

- 复杂几何: 有了先进的数控机床,制造商就能制造出复杂的形状,而这些形状是手工工艺难以实现或无法实现的。这种能力对于开发创新产品和部件至关重要。

- 减少浪费: 由于精密加工非常精确,因此可以最大限度地减少材料浪费。这种高效率不仅节省了原材料,还降低了生产对环境的整体影响。

- 速度 现代精密加工技术高度自动化,与传统方法相比,生产时间更短。这种速度使项目的周转时间更快,与市场需求保持同步。

应用

Applications of Precision Machining

各行各业都依赖精密数控加工服务来制造专用零件,其中包括

- Engine Components: Essential for engines in both the automotive and aerospace industries, such as pistons and crankshafts, which require exact dimensions for optimal performance.

- Electronics Parts: Critical in producing components like connectors and pins in electronic devices, where precise measurements are necessary for functionality and compact assembly.

- Medical Implants: Used to manufacture surgical implants, including hip and knee replacements, where precise tolerances and smooth finishes are crucial for compatibility with human tissue.

- Aerospace Fasteners: Involves creating high-strength bolts and screws that must endure extreme environmental conditions in aerospace applications.

- Tool and Die Making: Focuses on crafting molds and dies that are fundamental in other manufacturing processes, ensuring the production of consistent and quality parts in mass production settings.

Overmolding vs Insert Molding