Custom Injection Molding Services

- T1 sample as fast as 2 weeks

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

- Fast, reliable production with high-quality results every time

通过我们的专业原型设计服务,快速准确地实现您的产品创意。

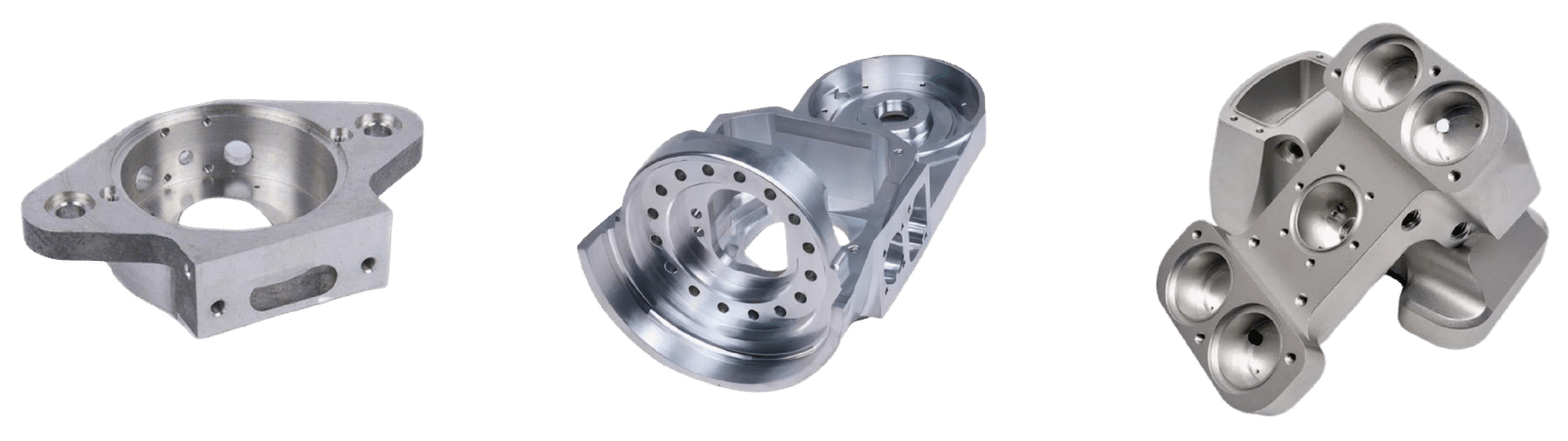

Custom Plastic Injection Molding for Precision Parts

Lewei Precision offers custom injection molding solutions for both prototypes and large-scale production. With our range of 90 to 830-ton machines, we produce high-quality plastic parts, no matter the size or complexity. Count on us for expert guidance throughout the design-to-production process, ensuring smooth and efficient project execution.

Our Injection Molding Manufacturing Network

Lewei Precision’s expansive network, featuring over 50 advanced machines handling up to 830 tons, efficiently manages projects from prototypes to large-scale production. Each project starts with a comprehensive injection mold quote to set clear expectations. Our expert project managers offer detailed manufacturing analysis and consultative design services to enhance cost efficiency and functionality.

Injection Molding Materials

机械加工、阳极氧化、粉末喷涂、电镀、喷漆、喷砂、抛光

铜具有高度导电性和延展性,是电线和管道的首选。铜的天然抗菌特性也使其成为医疗应用的理想材料,同时其美观性也适合装饰品和艺术品。

橘红色

铜 C101(T2)、铜 C103(T1)、铜 C103(TU2)、铜 C110(TU0)、铍铜

机加工、抛光、喷砂、滚揉、电抛光、镀铝、热处理、黑色氧化、化学镀镍、镀铬、拉丝处理

$$$

约 5 个工作日

青铜是铜和锡的合金,以耐用和耐腐蚀而著称。青铜的强度和耐恶劣环境的能力使其广泛应用于航海、雕塑和轴承等领域。

金属棕色

锡青铜

机加工、抛光、喷砂、滚揉、电抛光、镀铝、热处理、黑色氧化、无电解镍、镀铬、粉末喷涂、拉丝处理

约 5 个工作日

钢是一种坚固且用途广泛的材料,广泛应用于建筑和制造业。高抗拉强度使其适用于结构部件,而不同的子类型则增强了其在工具和机械等特殊应用中的性能。

银灰色

钢 1018、1020、1025、1045、1215、4130、4140、4340、5140、A36、模具钢、合金钢、凿形工具钢、弹簧钢、高速钢、冷轧钢、轴承钢、SPCC

机加工、电镀、钝化、粉末喷涂

约 7 个工作日

不锈钢具有防锈和防污的特点,是厨房用具和医疗设备的理想材料。其强度和美观性也使其成为建筑设计和汽车部件的热门选择。

银灰色

不锈钢 SUS201、SUS303、SUS 304、SUS316、SUS316L、SUS42、SUS430、SUS431、SUS440C、SUS630/17-4PH、AISI 304

机加工、电镀、钝化、粉末喷涂

约 7 个工作日

镁重量轻而强度高,常用于对减重要求极高的航空航天和汽车应用领域。镁的机加工性能使其可以加工出复杂的形状,同时它还因其出色的导电性能而被广泛应用于各种电子设备中。

白银色

镁合金 AZ31B、AZ91D

机加工、抛光、喷砂、滚揉、镀铝、热处理、阳极氧化、特氟龙涂层、非电解镍、喷漆、粉末涂层、电泳

约 8 个工作日

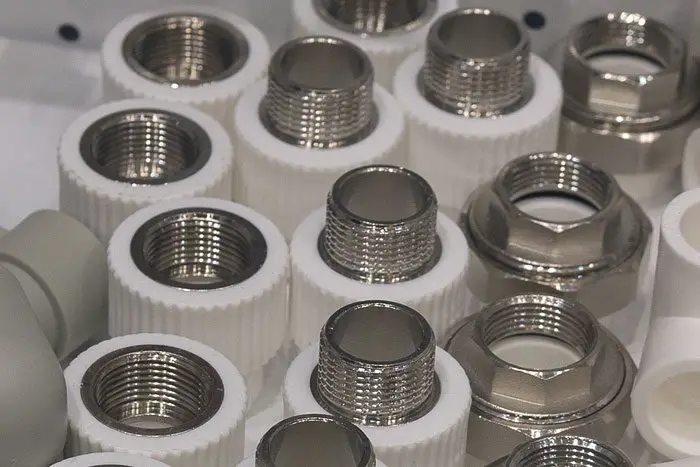

Injection Mold Surface Finishes

Lewei Precision provides SPI surface finishes for injection molded parts, tailored to your project’s requirements. Our experts are ready to guide you in selecting the ideal finish.

Provides a smooth, high-gloss surface for parts requiring superior aesthetic appeal and visual quality.

Creates a matte, durable surface that enhances grip and hides fingerprints, often used in industrial parts.

Achieves a uniform, matte surface with texture, ideal for better handling or improved assembly.

Uses abrasive media to refine surfaces, offering a smooth or matte finish for complex parts.

Applies a highly reflective, durable layer for corrosion resistance, commonly used in automotive and decorative parts.

Engraves intricate patterns or designs on parts for precise logos, textures, and unique markings.

数控加工公差

特点 | 说明 |

最大部件尺寸 | 1200 × 1000 × 500 mm |

最小部件尺寸 | 5 × 5 × 5 mm |

Part to Part Repeatability | ±0.1 mm |

Mold Cavities | Single-cavity, multi-cavity, family molds |

Available Mold Types | Steel and aluminum molds, suitable for varying production levels |

Production Levels | Below 1000, 5000, 30000, and over 100000 units |

Mold Cavity Tolerances | ±0.02 mm |

Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts, and assembly |

暗挖 | Y-type, L-type undercuts |

Wall Thickness | 0.5 mm to 5 mm |

Draft | 0.5° to 2° |

Ribs/Gussets | 0.5 mm to 3 mm thick |

Bosses | Diameter 3 mm to 10 mm |

准备时间 | Most orders completed within 15 working days |

数控加工设计指南

特点 | 说明 |

Wall Thickness | Uniform thickness of 1.5 mm to 3 mm is recommended. Avoid excessively thick or thin walls to prevent warping. |

Radii and Corners | Minimum radius of 0.5 mm for internal corners. Avoid sharp corners to reduce stress points and aid in mold release. |

Draft Angles | Draft angle of 1° to 2° is recommended on vertical walls to ensure smooth part ejection. |

暗挖 | Use side actions or lifters to accommodate undercuts. Proper mold design is necessary for parts with undercuts. |

Tolerances | Standard tolerance of ±0.1 mm. For tighter tolerances (±0.01 mm), specialized molds are required. |

Text and Logos | Minimum engraving depth of 0.1 mm and width of 0.5 mm. CNC engraving or laser marking is used for text/logo creation. |

Holes and Features | Minimum hole diameter of 1.5 mm. For holes larger than 5 mm, inserts or core pins are recommended. |

Parting Line and Gate | Gates should be placed to minimize defects, and parting lines should be positioned in non-visible areas. |

Material Selection | Choose appropriate materials such as ABS, polycarbonate, or nylon, depending on the part’s intended use. |

Injection Molding Design Guide

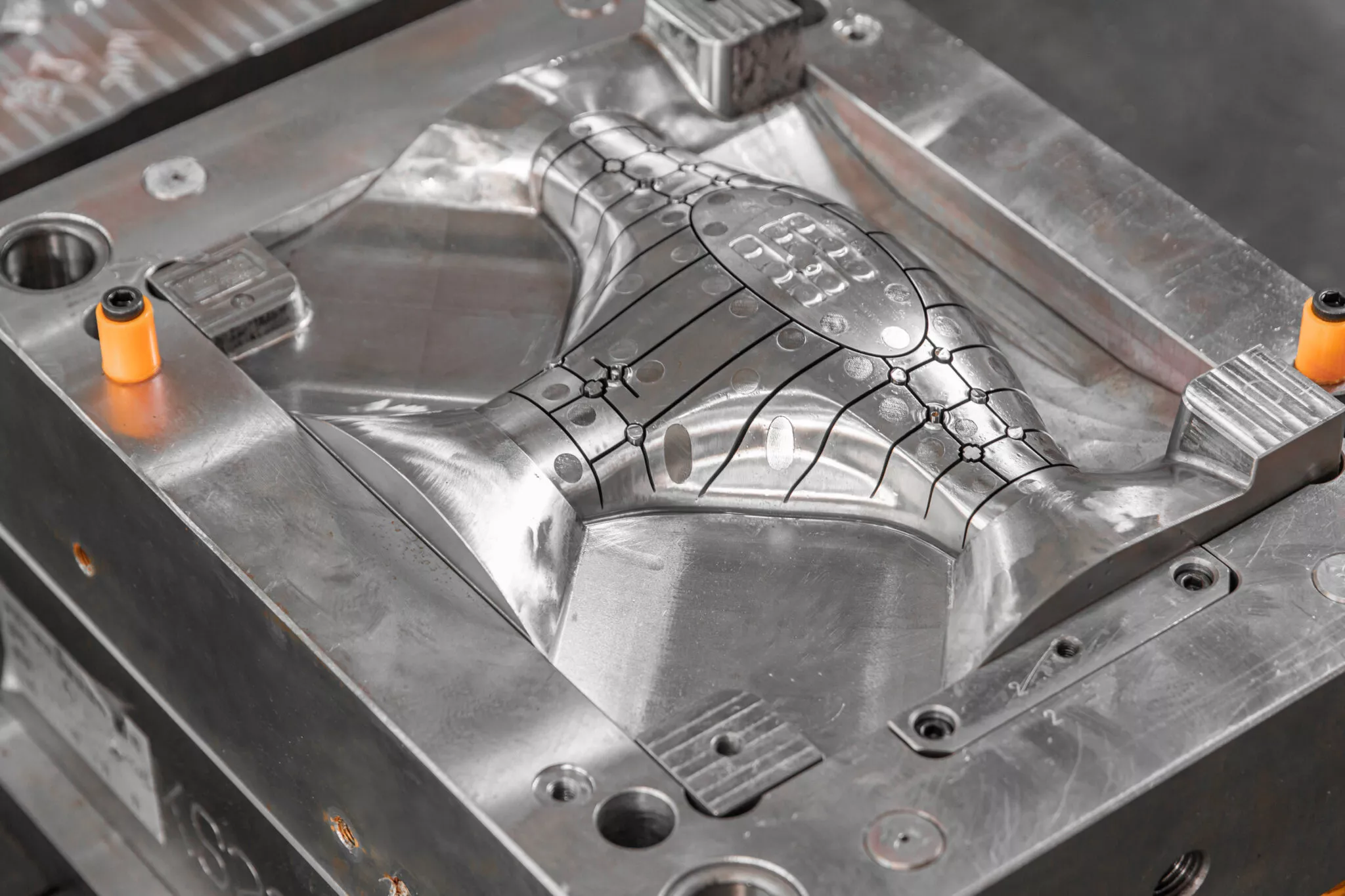

Commitment to Unmatched Quality in Plastic Injection Molding

We are dedicated to delivering top-tier plastic injection molded components by maintaining rigorous quality standards at every stage of production. From the very first design phase through to the final product inspection, our goal is to ensure every part is crafted with utmost precision and reliability.

Our process begins with a detailed Design for Manufacturability (DFM) review, where our team works closely with clients to refine designs and optimize them for molding, minimizing potential issues in production.

With ISO 9001:2015 certification, and a commitment to continuous improvement, Lewei Precision ensures the highest standards of quality across every product we manufacture.

- 认证:ISO 9001:2015、ISO 13485、ISO 14001、IATF 16949

- Experienced team of quality engineers

- State-of-the-art inspection equipment

Prototyping Injection Molding

Get custom plastic prototypes and production parts with flexible solutions from Lewei Precision.

Lewei Precision offers rapid prototyping services for injection molding, delivering high-quality prototypes with quick lead times. We provide flexible material options and expert DFM assistance to help you test functionality and validate designs efficiently.

- Quantity: 1-100 pcs

- 准备时间: 1-3 weeks

- Tooling: Soft tooling or 3D-printed molds

- Key Features: Low-volume, high-quality plastic parts

- Quantity: 1-100 pcs

- 交付时间:1-3 周

- Soft tooling or 3D-printed mold used

Lewei Precision’s low-volume injection molding uses aluminum tooling to produce complex plastic parts quickly and cost-effectively. This service is perfect for design validation, inventory control, and a supply chain capable of adapting to fluctuating demand.

- Quantity: 100-10,000 pcs

- 准备时间: 3-6 weeks

- Key Features: Fast, cost-efficient production of low-volume plastic parts

High-volume injection molding provides a reliable and affordable solution for mass-producing identical, precise parts. With state-of-the-art equipment and rigorous quality control, we ensure tight tolerances and consistent quality across a range of plastic materials to suit your requirements.

- Quantity: Over 10,000 pcs, can scale into the millions

- 准备时间: 4-12 weeks or more

- Materials Available: 100+ thermoplastic and thermoset materials

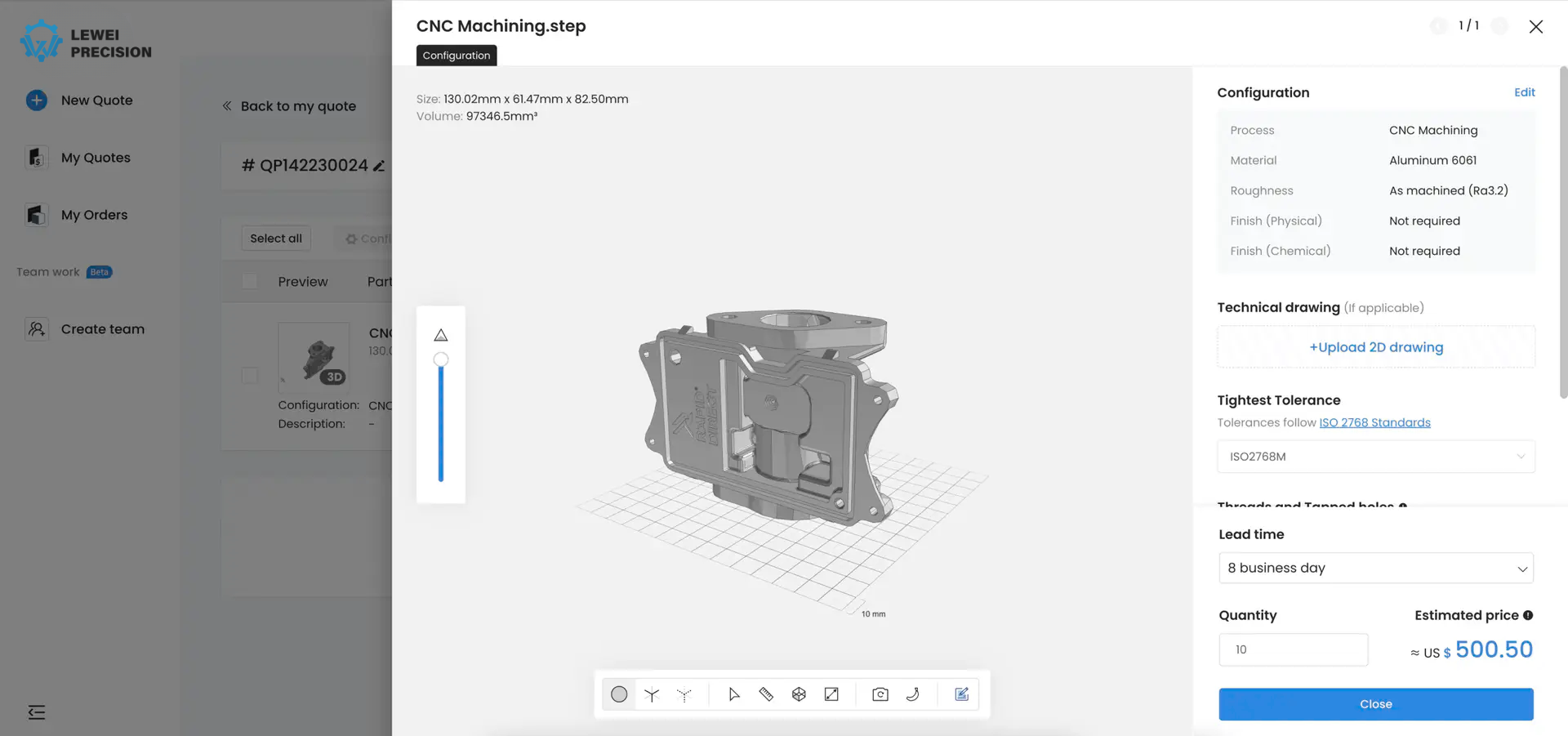

启动您的数控加工项目

Comprehensive Injection Molding Solutions for Diverse Industries

Lewei Precision offers tailored injection molding services to meet the unique needs of various industries, ranging from automotive to electronics. Our commitment to precision and cost-effectiveness ensures that we provide high-quality, custom solutions for every application.

成功案例

乐威精密 x 斯图加特 Rennteam:赛车工程的创新合作

乐为精密自豪地为斯图加特 Rennteam 车队提供支持,生产 2 个主杆部件和 80 多个铝制镶件。我们的精密工程技术确保这些部件能够征服大学生方程式赛车比赛,为车队带来制胜优势。

案例研究:LURA 与乐为精密合作生产精密火箭发动机部件

利兹大学火箭协会(LURA)利用乐为精密的五轴数控加工和车铣复合加工技术,制造出了复杂的发动机部件,这对他们在全国太空推进竞赛中取得胜利至关重要。

案例研究:Andrea Piccino 与 Lewei Precision 合作,将 "钢铁侠战衣 "带入生活

来自意大利的专职机械工程师安德烈亚利用乐为精密的五轴数控加工技术,制造出了一种全身被动式外骨骼,这种外骨骼可以增强人体力量,最大限度地减轻身体负担。

为什么选择我们

Customization

Lewei Precision excels in providing customized injection molding solutions tailored to the specific needs of each industry.

Utilizing state-of-the-art machinery and precision tooling, Lewei Precision ensures that every part is manufactured with tight tolerances and superior quality.

Lewei Precision offers fast lead times and scalable production, making us a reliable partner for projects of any size.

数控加工常见问题

What are the typical lead times for injection molding projects at Lewei Precision?

Lead times vary, with prototypes taking 1-3 weeks, low-volume production 3-6 weeks, and high-volume production 4-12 weeks.

How does Lewei Precision ensure the quality of injection molded parts?

We employ strict quality control through DFM reviews, inspections, and advanced tools like CMMs, ensuring precision at every step.

Can Lewei Precision handle both low and high-volume production runs?

Yes, we handle both low-volume (100-10,000 pcs) and high-volume production (10,000+ pcs), adapting to your specific needs.

What types of tooling does the company use for injection molding?

We use soft tooling for prototyping, aluminum tooling for low-volume, and steel tooling for high-volume production.