Lewei Precision accelerates new product development for the medical industry with on-demand manufacturing solutions, ensuring high-quality and efficient production.

Lewei Precision offers reliable medical device prototyping and production, from simple to complex medical parts. By combining advanced technologies with exceptional manufacturing expertise, we bring your medical products to life in the most efficient ways. Regardless of the part’s complexity, we help you achieve your goals through rapid prototyping, bridge tooling, and low-volume production.

我们通过 ISO 认证的 CNC 加工可确保精度和质量。每一个零件都经过先进的质量控制,完美匹配,性能无懈可击。

随时随地满足您的数控加工需求。我们的专家可提供支持,最大限度地提高设计效率和质量。

Create high-quality prototypes using production-grade materials for early-stage development. Analyze your design and make necessary changes to optimize materials or design for testing. Our technicians will craft prototypes based on your design file, ensuring they meet your specifications. The materials and processes we choose will depend on your application, bringing your component closer to the final product.

Make quick adjustments to functional medical device prototypes after engineering testing and validation of performance standards. We create functional prototypes that closely resemble the final product, allowing you to easily identify and address any design issues.

Validate your medical product’s performance, functionality, and appearance efficiently. Make necessary design iterations to reduce production time and costs. We provide high-quality designs and manufacturing feedback to help you assess both the performance and appearance of your medical prototypes.

Prepare your design for mass production with production-grade machining processes and a robust quality management system. Gain valuable feedback from our technical team to assess the manufacturability and suitability of your product, allowing you to make final adjustments for more efficient production.

Transition smoothly from product testing to large-scale production of end-use medical parts. Implement precise quality standards and exceptional manufacturing capabilities to deliver high-quality products. Lewei Precision elevates your medical device production with advanced manufacturing processes and engineering expertise.

Lewei Precision offers exceptional manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our in-house facility and a vast global manufacturing network, we are equipped to efficiently deliver complex, high-quality parts.

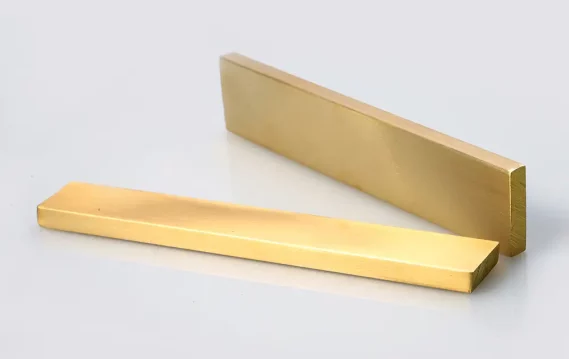

通过铣削、车削和后处理实现精确、复杂的设计,使其成为复杂原型和功能性金属部件的完美选择。

快速生产模制零件和桥接模具,优化大批量生产并保持稳定的质量。

在成形精密金属部件方面具有多功能性,适合各种应用,确保适应性和精确性。

这种方法快速而灵活,能迅速用各种材料制作出复杂的几何形状,是创新设计的理想选择。

用各种材料生产均匀的长形零件,优化生产效率和材料利用率,是一种经济有效的方法。

这种工艺非常适合高精度金属零件的制造,在大批量生产中表现出色,所有零件的质量始终如一。

是生产高质量原型或小批量终端零件的理想选择,可提供卓越的细节和光洁度。

在切割复杂、坚硬的材料时具有无与伦比的精确度,非常适合切割精细、复杂的部件。

Lewei Precision’s extensive production capabilities enhance medical device manufacturing to support various healthcare applications. Some of the key applications include: