Overmolding Service

Lewei Precision offers high-quality custom overmolding for prototypes and on-demand production parts. With rapid tooling production, we can deliver parts in as little as 2 weeks.

- T1 sample as fast as 2 weeks

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

- Fast, reliable production with high-quality results every time

Lewei Precision guarantees consistent high-quality custom overmolded parts through certified factories and thorough in-process inspections. We conduct dimensional verifications after production to ensure precision and reliability, even for complex shapes.

With our certified domestic facilities and efficient supply chain, we streamline the product development process, delivering your overmolded parts as quickly as possible while maintaining high standards.

Leverage the expertise of our engineers, who bring over 10 years of experience in injection molding, to efficiently guide your project from prototyping to full-scale production. We ensure a smooth transition at every stage of the process.

Unlock Precision and Speed with Custom Overmolding Services

At Lewei Precision, we specialize in providing custom overmolding services tailored to meet your specific needs. Whether you’re working on prototypes or require on-demand production parts, our team ensures high-quality, precision-engineered solutions. We use advanced techniques to bond different materials together, creating durable, functional parts that perform under demanding conditions. With our rapid tooling production, we can deliver your overmolded parts in as little as 2 weeks, allowing you to move swiftly from concept to market. Let Lewei Precision help bring your designs to life with reliable, cost-effective, and innovative overmolding solutions.

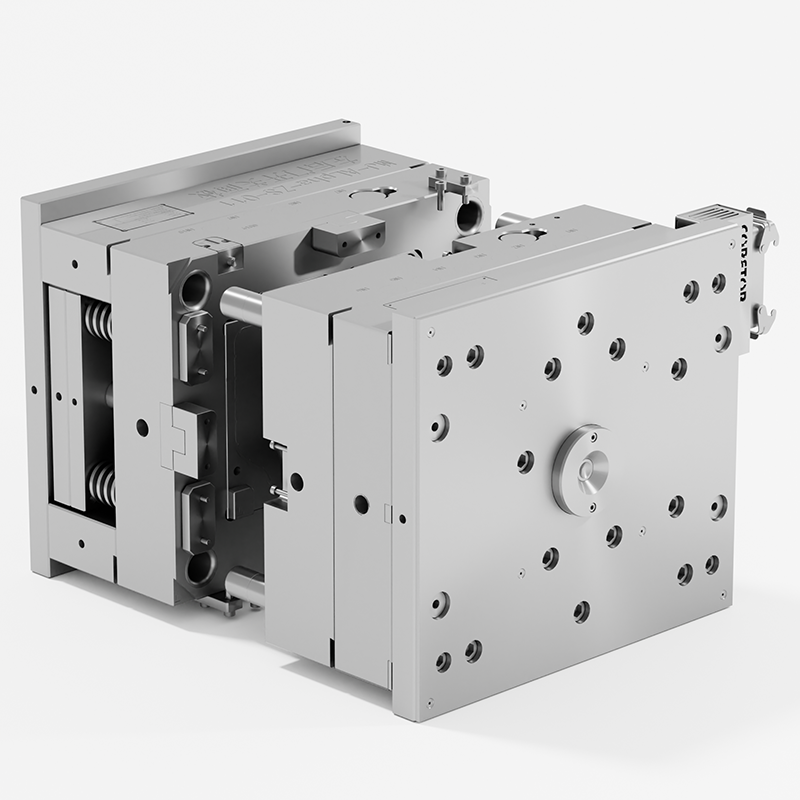

Overmolding Process

In mass production, the plastic over plastic overmolding process uses durable molds crafted from steel or aluminum. This ensures precise, repeatable part geometries for high-volume manufacturing.

- Ideal for large-scale production

- Achieves detailed geometries

- Uses aluminum and steel molds

Rubber overmolding enhances both the functionality and appearance of products by fusing different materials into one part. It adds features like soft grips and multi-color designs, improving usability.

- Offers various color and texture options

- Seamlessly combines materials

- Increases strength and lifespan

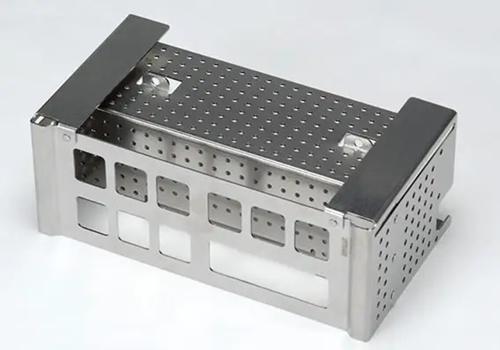

Plastic over metal insert molding incorporates metal or other materials into plastic parts during molding. This process boosts component strength while reducing assembly time for parts with embedded features.

- Lowers production costs

- Enhances durability

- Reduces assembly steps

Rubber over metal insert molding integrates metal components into plastic parts, offering improved strength and reduced assembly steps for products with embedded features.

- Cuts production costs

- Enhances durability

- Reduces assembly steps

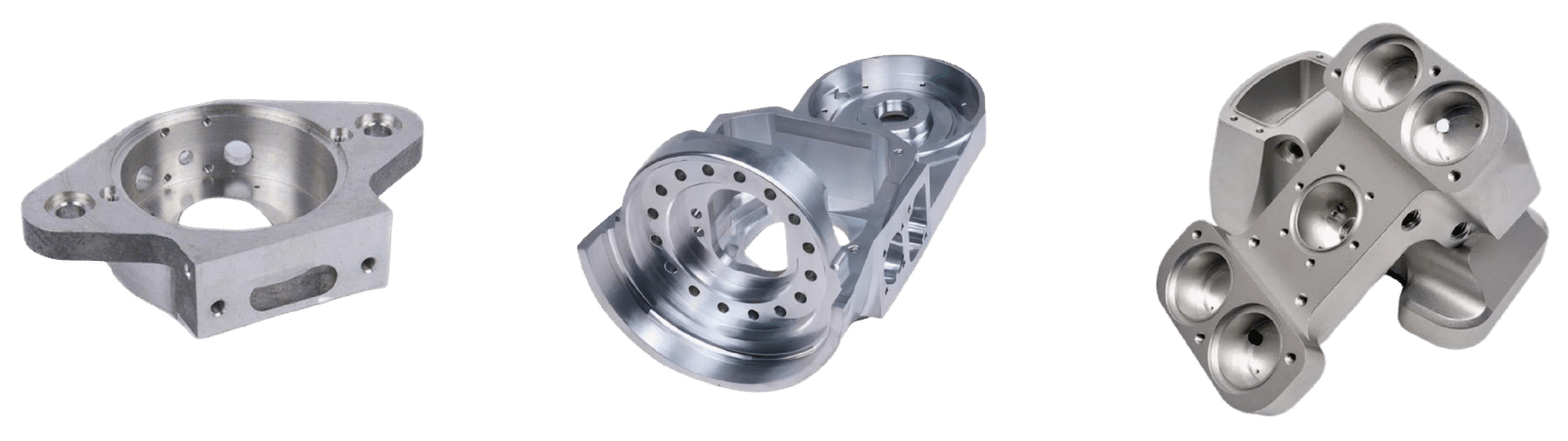

CNC Machining Solutions

Lewei Prototyping

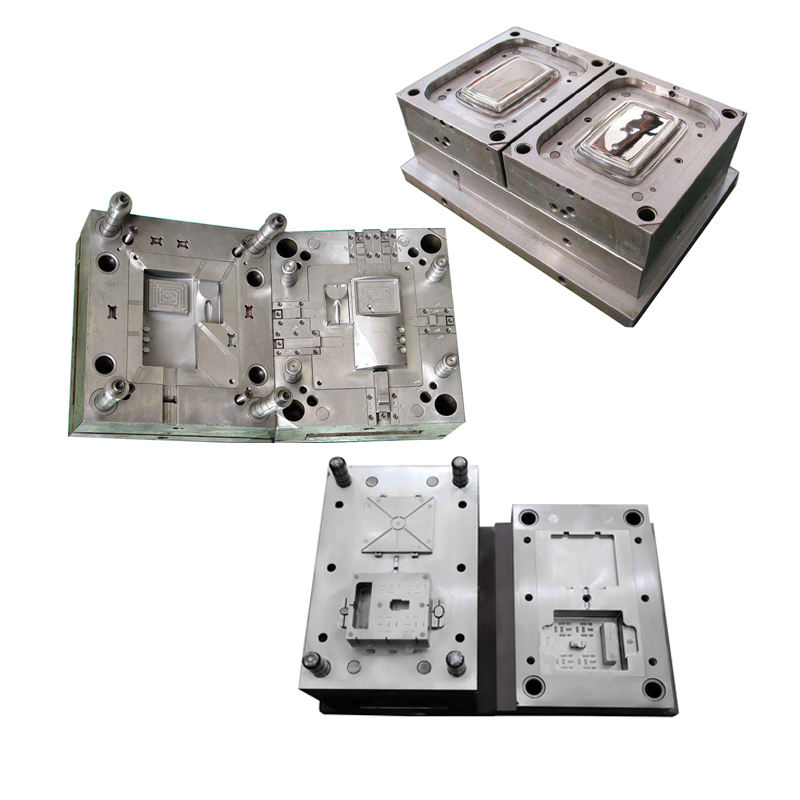

Lewei Precision provides high-quality prototype tooling to help you quickly validate your designs. Our process enables you to create small batches of plastic molded parts, allowing for functional testing and market validation in a fraction of the time. We specialize in manufacturing prototype molds within days, ensuring fast feedback and design improvements.

Our steel cavity and core molds have a shot life ranging from 1,000 to 5,000 shots and are typically produced within two weeks.

Production Tooling

Lewei Precision excels in creating high-quality production molds for high-volume plastic parts. We use high-strength, durable tool steel to ensure that our molds can produce hundreds of thousands of parts. Our tooling is customizable, with materials and construction methods tailored to your specific needs.

Our high-performance steel tools can endure up to 10,000 shots, with parts typically produced within 3 weeks.

Lewei Overmolding Finishes

SPI Finishes

Our SPI finishes range from Grade 3 diamond/high polish to 320 stone low polish. The available finishing options include SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

Polished Finish

Offers a smooth and shiny surface, often used for parts that require easy cleaning or a high-end look.

Satin Finish

A smooth, semi-gloss finish that provides a balance between matte and mirror finishes, suitable for both functional and aesthetic needs.

Materials for Overmolding at Lewei Precision

Lewei Precision’s custom overmolding services enable the creation of high-performance plastic parts that combine aesthetics and functionality. Our advanced injection molding process integrates multiple materials into a single part, delivering superior quality and improved product performance.

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

Overmolding Capabilities

Lewei Precision’s wire EDM, part of our CNC services, efficiently crafts both simple and intricate shapes. Ideal for parts requiring high precision, this no-contact method produces minimal burrs and excels with metals like steel and titanium. Favored in aerospace, automotive, and electronics for their accuracy, we ensure tailored, precise solutions regardless of your needs.

Capability

Details/Specifications

Material Compatibility

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper

Tolerance

± 0.0001 inches (0.0025 mm) or better (based on material and thickness)

Maximum Workpiece Size

Length: 16 inches (400 mm)

Width: 12 inches (300 mm)

Height: 8 inches (200 mm)

Cutting Speed

Up to 300 mm2/min (specific to material and thickness)

Surface Finish

As fine as Ra 0.2 µm

Maximum Cutting Thickness

Up to 12 inches (300 mm) – varies based on material

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

Wire Diameter Range

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm)

Advantages

Advantages of Overmolding at Lewei Precision

Overmolding significantly enhances the performance and aesthetics of your products by combining multiple materials into a single part. This process offers numerous benefits, from improved functionality to cost savings, making it an ideal choice for various applications.

- High Accuracy: Precision machining tools can produce parts with extremely tight tolerances, ensuring that each piece meets exact specifications. This is crucial for applications requiring intricate details, such as in aerospace and medical devices.

- Consistency: This method offers unmatched consistency in production. Even over large volumes, each part remains identical, reducing the risk of errors and defects in the final product.

- Material Versatility: Precision machining can handle a wide range of materials, from metals to plastics and composites. This flexibility allows manufacturers to choose the ideal material for specific properties like strength, weight, or resistance.

- Complex Geometries: With advanced CNC machines, manufacturers can create complex shapes that would be difficult or impossible to achieve through manual processes. This capability is vital for developing innovative products and components.

- Reduced Waste: Since precision machining is so accurate, it minimizes material wastage. This efficiency not only saves on raw materials but also reduces the overall environmental impact of manufacturing.

- Speed: Modern precision machining techniques are highly automated, leading to faster production times compared to traditional methods. This speed enables quicker turnaround times for projects, keeping pace with market demands.

Applications

Applications of Overmolding at Lewei Precision

The versatility of the injection overmolding process makes it ideal for a wide array of industries. In addition to the previously mentioned applications, here are several more where overmolding is extensively used:

- Engine Components: Essential for engines in both the automotive and aerospace industries, such as pistons and crankshafts, which require exact dimensions for optimal performance.

- Electronics Parts: Critical in producing components like connectors and pins in electronic devices, where precise measurements are necessary for functionality and compact assembly.

- Medical Implants: Used to manufacture surgical implants, including hip and knee replacements, where precise tolerances and smooth finishes are crucial for compatibility with human tissue.

- Aerospace Fasteners: Involves creating high-strength bolts and screws that must endure extreme environmental conditions in aerospace applications.

- Tool and Die Making: Focuses on crafting molds and dies that are fundamental in other manufacturing processes, ensuring the production of consistent and quality parts in mass production settings.

Overmolding vs Insert Molding