Custom Die Casting Services

We specialize in die casting, delivering high-quality metal parts with precision and efficiency, making it the perfect solution for large production runs.

- Durable, smooth surface finishes for functional and aesthetic parts

- Quick-turn prototypes and production parts in days

- Ideal for large-scale production and complex geometries

Lewei Precision Die Casting Factory and Equipment

Lewei Precision Die Casting Capabilities

Specification | Details |

Tolerance | Secondary machining required for high-precision parts. Achieves accuracy up to ±0.01mm. |

Espesor mínimo de pared | Aluminum: 1.5mm recommended; Zinc: can go down to 0.8mm. |

Wall Thickness Ratio | Keep within 1:3 ratio to prevent uneven filling. |

Hole Diameter | Round holes <3mm in aluminum require secondary drilling. Threaded holes formed via secondary machining. |

Draft Angle | Minimum 0.5° to avoid demolding issues. |

Maximum Die Life | Zinc: 1,000,000 cycles; Magnesium & Aluminum: 100,000 cycles. |

MOQ | 500–1000 pieces. |

Plazos de entrega | 20–25 days, depending on mold type and product complexity. |

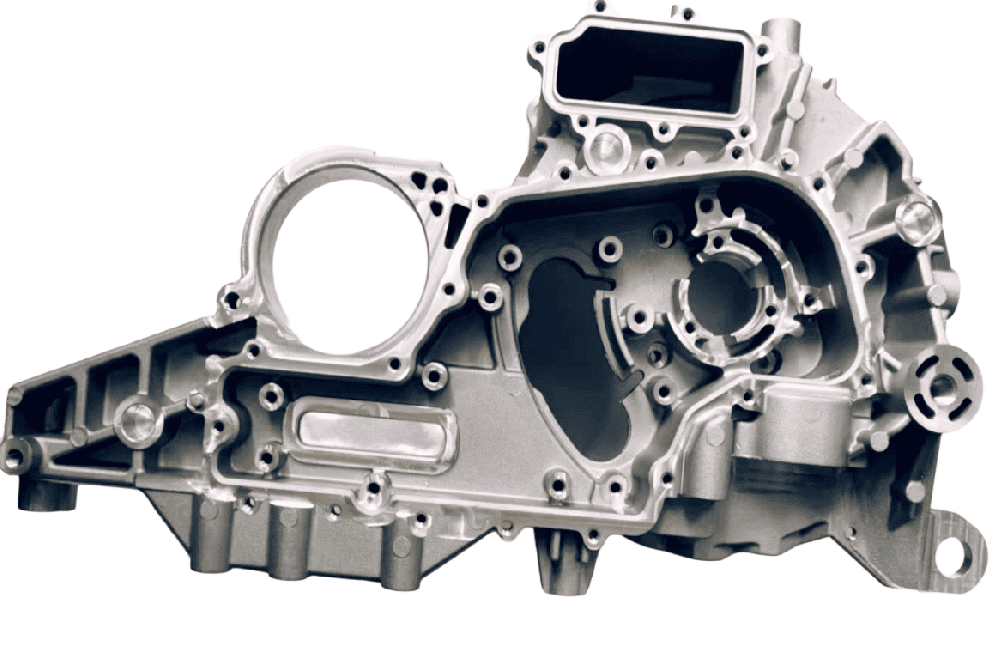

Die Casting Parts We Manufacture

Types of Die Casting Processes at Lewei Precision

To meet diverse project requirements, Lewei Precision offers three types of die casting machines, optimized for various materials and design complexities. We mainly use hot and cold chamber casting. For parts requiring tight tolerances and enhanced structural strength, we provide advanced methods such as semi-solid casting.

Die Casting Materials & Finish

Die-cast tooling uses hardened steel to withstand high temperatures and pressure. Non-ferrous metals are preferred for die-casting due to their fluidity and low melting points. Ferrous metals are used in some cases but are less common.

Choose from a wide range of polyurethane resins and silicone mold options that closely replicate the look, feel, and performance of end-use parts. Custom requests are welcome.

Strong at high heat. Tough and crack-resistant. Stays hard when hot. Good for aluminum and magnesium casting.

Handles heat changes well. Tougher than H13 steel. Conducts heat better and lasts longer. Good for heavy-duty casting work.

Strong at high heat. Resists cracking from heat cycles. Easy to machine and polish. European steel grade for detailed parts.

Lightweight, corrosion-resistant, good strength-to-weight ratio. Used for complex, thin-walled car parts, airplane parts, and electronics.

- ADC10

- A380

- ADC12

- Pure Aluminum

- HA6

- HA4

- 6063

High strength, good machinability, and EMI shielding. Often used in electronics, automotive components, and handheld device housings.

- AM50A

- AM60B

- AZ91D

Flows well in molds and holds tight tolerances. A good choice for small, detailed parts. Often used in electronics, connectors, locks, and everyday hardware for its strength and low cost.

- ZAMAK5

- ZAMAK3

- ZAMAK2

Die-cast components, especially zinc and aluminum parts, naturally have smooth surfaces. To improve aesthetics, durability, or corrosion resistance, explore the surface finishes Lewei Precision offers. For special requests, feel free to contact us.

Abrasive blasting that removes surface impurities and gives a uniform, matte texture. It also improves paint or coating adhesion.

Adds color and improves appearance while offering additional protection against corrosion and wear. Often used for branding or meeting specific design requirements.

Provides a basic, functional finish for die-casting products with relatively smooth surfaces and minor tool marks, suitable for non-cosmetic applications.

Pros and Cons of Die Casting

High strength-to-weight ratio reduces overall load

Natural oxide layer protects against rust and degradation

100% recyclable material supports sustainability goals

T-slot compatibility and simple joining methods

Complex profiles possible in a single extrusion process

Lower machining costs compared to solid aluminum blocks

Die manufacturing requires upfront Extrusion lines may need finishing or polishing

Mechanical strength decreases at high heat

Design changes need new tooling

Setup and trimming create scrap material

Press capacity limits maximum profile dimensions

FAQs

What should I consider when designing for die casting?

When designing parts for die casting, several key considerations must be addressed to ensure optimal performance and manufacturability:

- Wall Thickness: Maintain uniform wall thickness to promote even cooling and solidification, reducing risks of defects like warping or internal stresses. Thin walls are preferred for faster cooling and material savings, but their feasibility depends on the metal used and part complexity.

- Draft Angles: Include draft angles in the design to facilitate easy removal of the casting from the die. Typically, a minimum draft angle of 1 to 2 degrees is necessary, depending on the depth of the part.

- Fillet and Radii: Incorporate fillets and radii to eliminate sharp corners and edges, which can cause stress concentrations and crack initiation points. This adjustment also enhances the flow of molten metal within the die.

Gating System: Design an efficient gating system to ensure proper flow of the molten metal into the die, minimizing turbulence and air entrapment. The placement of gates influences material distribution and part quality.

- Venting: Proper venting must be planned to allow air and gases to escape from the mold cavity during metal injection. This helps prevent porosity and incomplete filling.

Simplifying Geometry: Simplify the geometry as much as possible to avoid undercuts and complex features that require intricate die mechanisms, which can increase tooling costs and complicate the casting process.

Can you post-machine die-cast parts?

Yes, post-machining of die-cast parts is not only possible but often necessary to achieve the desired precision and surface finishes that die casting alone might not provide. Post-machining allows for the attainment of tighter tolerances and smoother surfaces, which are crucial for high-performance and aesthetic requirements. Common post-machining processes include drilling, milling, and CNC machining, which refine the features of the die-cast part to exact specifications.

Additionally, post-machining can correct any minor defects that occur during the casting process, such as porosity or surface imperfections. It also enables the addition of complex features and fine details that cannot be achieved through casting alone. By integrating die casting with post-machining, manufacturers can leverage the speed and cost-efficiency of die casting for the rough shape while achieving the precision of CNC machining for critical dimensions and finishes.