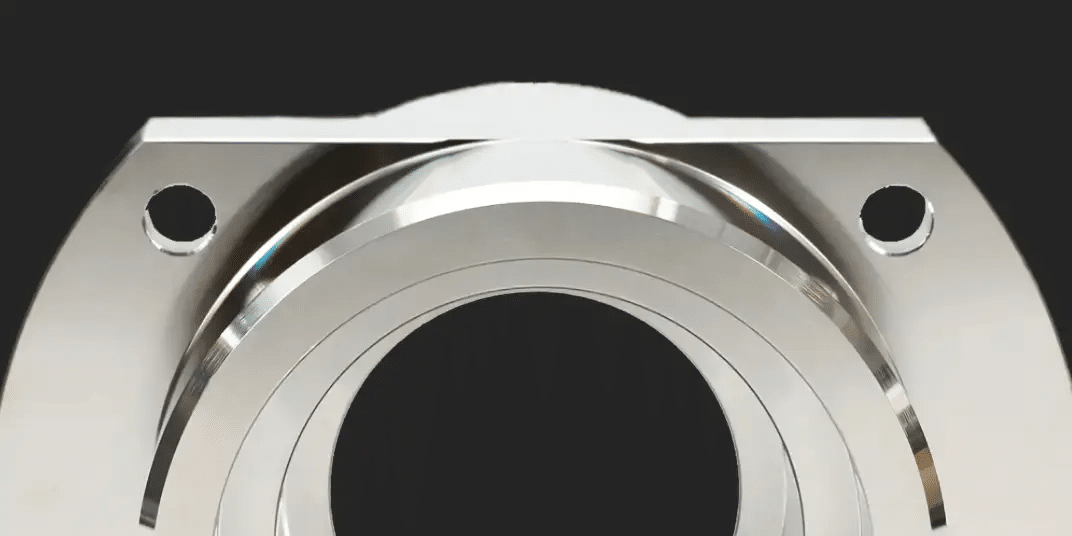

Custom Online CNC Turning Services

Lewei Precision offers custom CNC turning services with quick turnaround times and competitive pricing, from rapid prototyping to full production runs. Achieve tight tolerances as precise as 0.005 mm, with lead times as short as 1 day.

Dé vida a sus ideas de producto de forma rápida y precisa con nuestros servicios expertos de creación de prototipos.

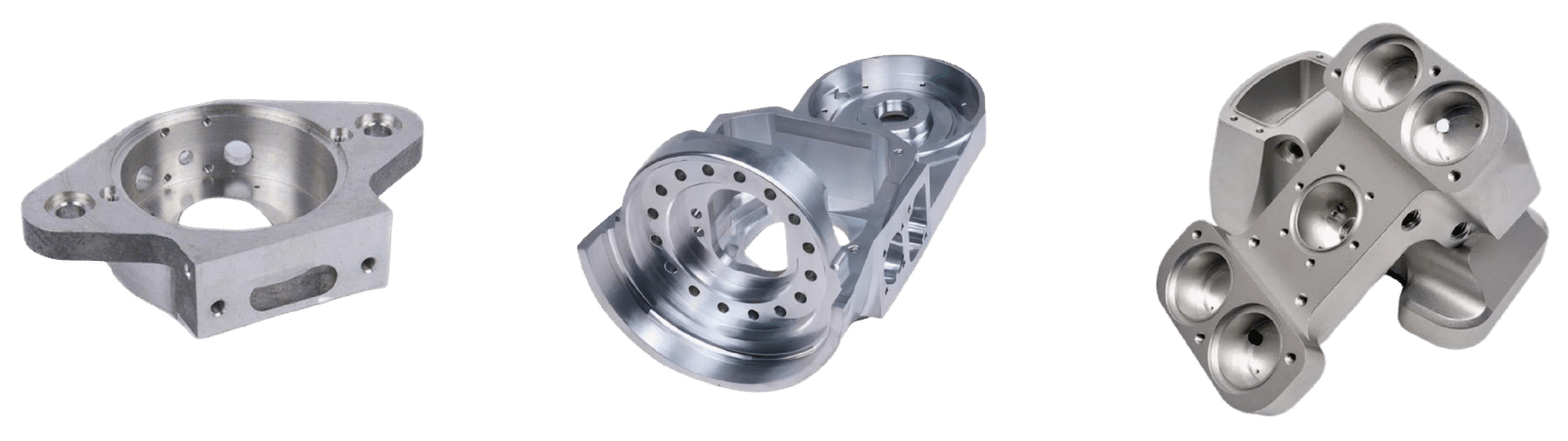

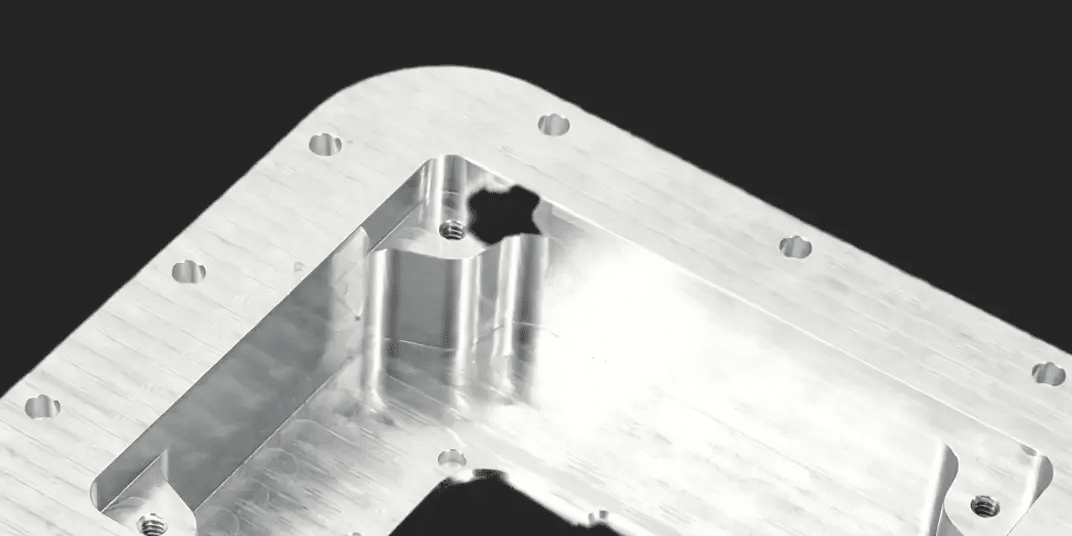

Custom CNC Turning

Custom CNC Turning Solutions for Every Need

Creación rápida de prototipos

Speed up product development with Lewei Precision’s rapid machining services. We provide fast turnaround times and specialize in the quick production of high-quality prototypes and mold tooling, helping you streamline the design verification process.

Custom Production for Any Volume

From small batches to large-scale production, Lewei Precision delivers both. With strict tolerance controls and versatile capabilities, we tailor our services to meet your volume needs while maintaining exceptional quality.

CNC Turning Materials

Lewei Precision’s CNC turning services accommodate a wide range of materials, from machine-grade metals to plastics. Whether you need precise turning of aluminum or other materials, we specialize in producing accurate prototypes and low-volume production runs tailored to your specifications. Explore some of the most commonly used materials for your CNC turning projects.

Metals

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Estaño Bronce

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloy

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

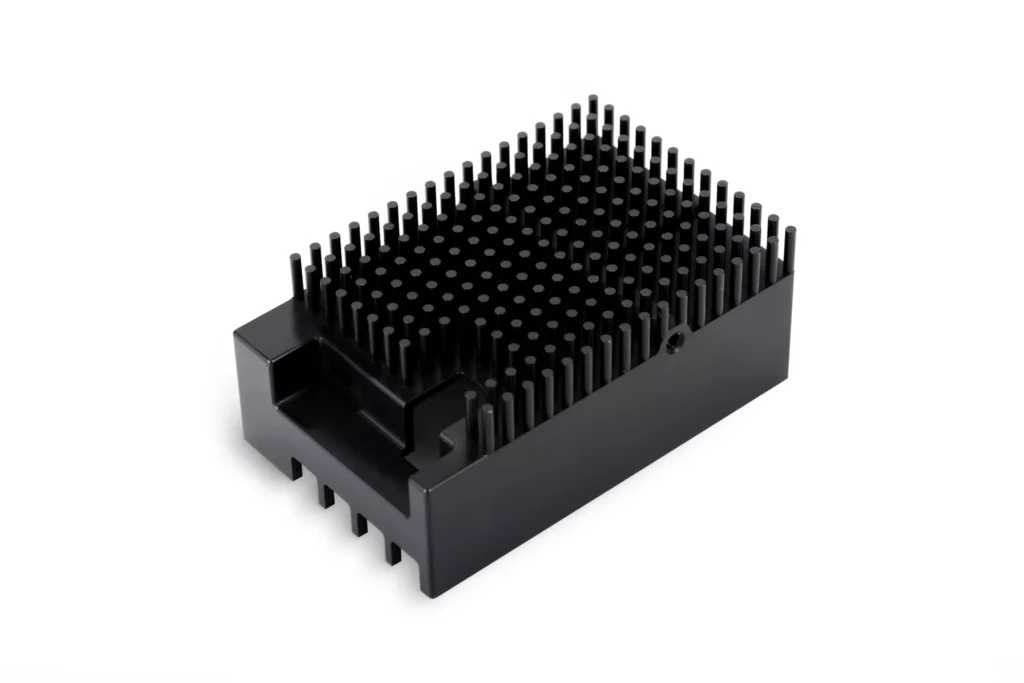

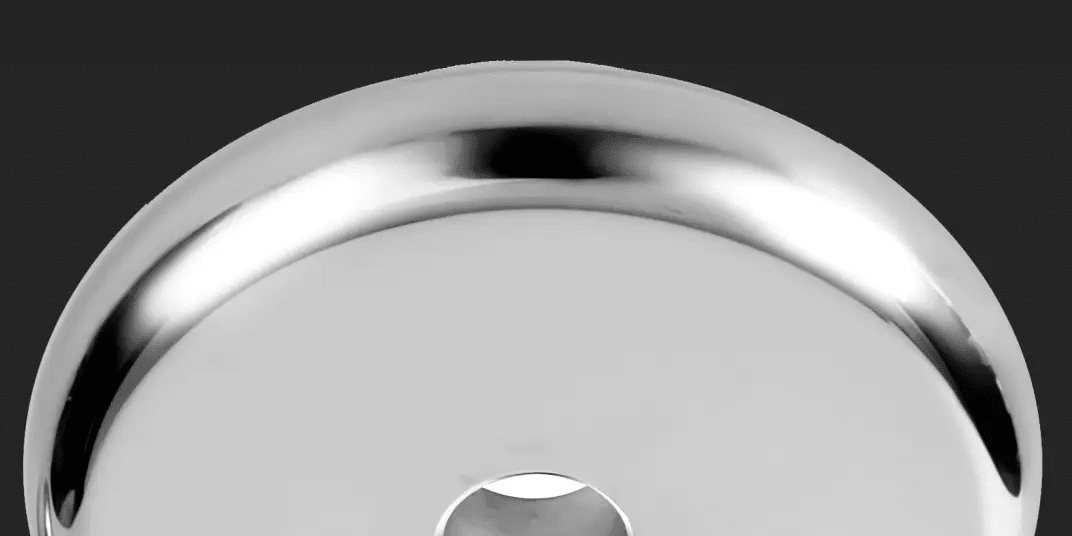

CNC Turning Surface Finishes

With a wide selection of surface finishes, Lewei can help improve the surface qualities of your products. Surface finishes applied to your CNC turned parts aim at improving their appearance, surface hardness and roughness, chemical and corrosion resistance, etc. They also help hide any visible tool marks from areas cut with live tooling. Here are some of your top choices.

Tolerancias de mecanizado CNC

| Características | Descripción |

|---|---|

| Tolerancias generales | Metals: ISO 2768-m Plastics: ISO 2768-c |

| Tolerancias de precisión | Lewei can manufacture and inspect parts with strict tolerances according to your drawing specifications and GD&T annotations, including tolerances tighter than ±0.001 inches. |

| Min Wall Thickness | 0,5 mm |

| Min End Mill Size | 0,5 mm |

| Min Drill Size | 1 mm |

| Tamaño máximo de la pieza | CNC Milling: 4000 × 1500 × 600 mm CNC Turning: 200 × 500 mm |

| Tamaño mínimo de la pieza | CNC Milling: 5 × 5 × 5 mm CNC Turning: 2 × 2 mm |

| Volumen de producción | Prototyping: 1–100 pcs Low volume: 101–10,000 pcs High volume: Above 10,001 pcs |

| Plazos de entrega | 5 business days for most projects Simple parts: as fast as 1 day |

Directrices de diseño para el mecanizado CNC

| Características | Descripción |

|---|---|

| Tolerancias generales | Metals: ISO 2768-m Plastics: ISO 2768-c |

| Tolerancias de precisión | Lewei can manufacture and inspect parts with strict tolerances according to your drawing specifications and GD&T annotations, including tolerances tighter than ±0.001 inches. |

| Min Wall Thickness | 0,5 mm |

| Min End Mill Size | 0,5 mm |

| Min Drill Size | 1 mm |

| Tamaño máximo de la pieza | CNC Milling: 4000 × 1500 × 600 mm CNC Turning: 200 × 500 mm |

| Tamaño mínimo de la pieza | CNC Milling: 5 × 5 × 5 mm CNC Turning: 2 × 2 mm |

| Volumen de producción | Prototyping: 1–100 pcs Low volume: 101–10,000 pcs High volume: Above 10,001 pcs |

| Plazos de entrega | 5 business days for most projects Simple parts: as fast as 1 day |

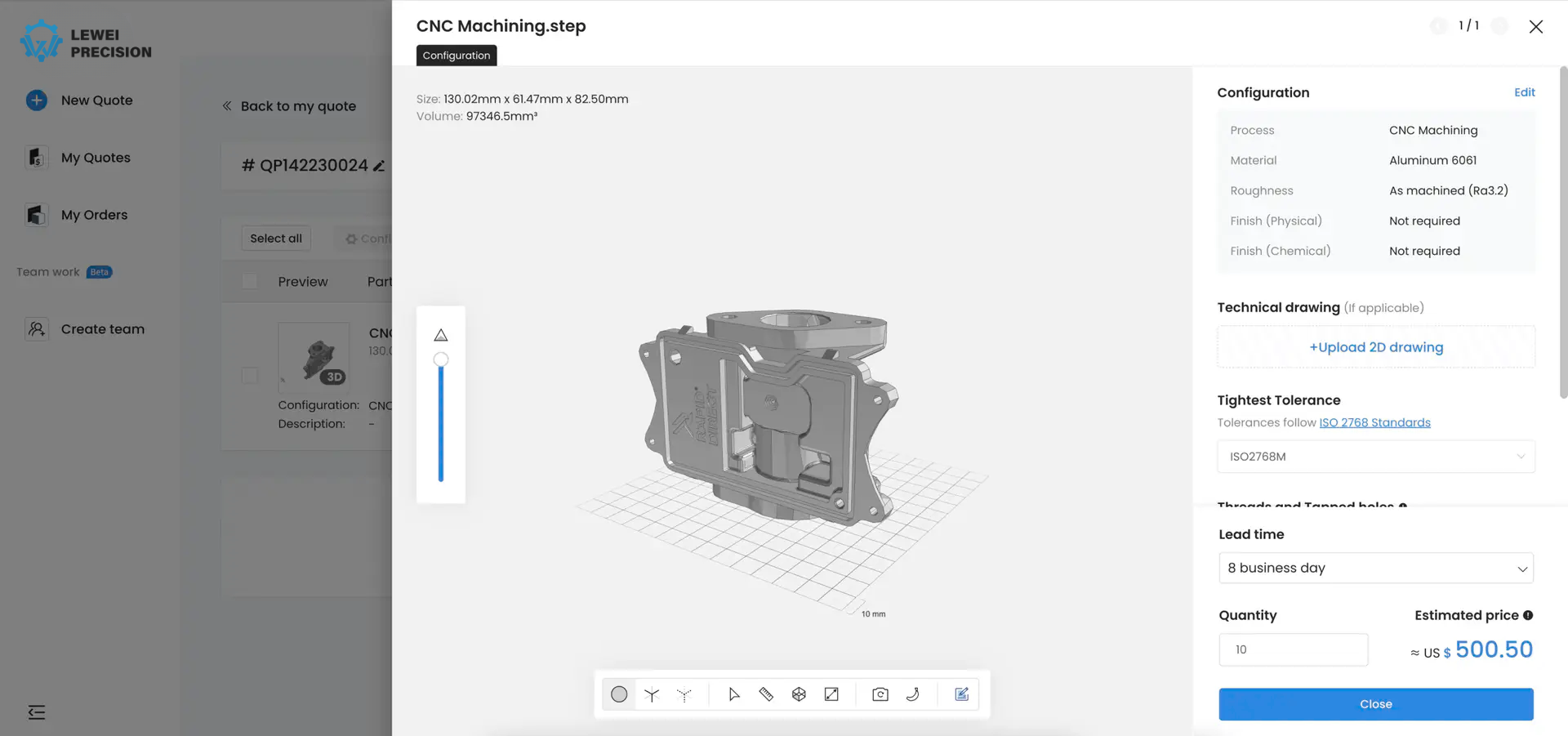

Comience su proyecto de mecanizado CNC

Cargue su archivo CAD para obtener al instante presupuestos, plazos de entrega e información DFM. Varios materiales, producción flexible y opciones de envío disponibles.

Lewei Precision is your trusted CNC turning partner, consistently delivering reliable and precise turning services across various industries. With our dedication and advanced technological methods, we provide complex prototypes and production parts that meet your exact specifications.

Choose Us

Piezas de alta calidad

Experience unmatched precision in every project. Our advanced CNC milling processes ensure components meet tight tolerances as precise as ±0.01mm, ensuring smooth assembly and optimal performance.

Speed up your production process with Lewei Precision. Our advanced workshops and cutting-edge machinery ensure rapid turnaround times, helping businesses stay on track and meet important deadlines efficiently.

Wherever and whenever you need it, navigate your CNC milling projects with confidence. Our experienced specialists provide expert guidance at every stage, ensuring optimal design and superior output quality.

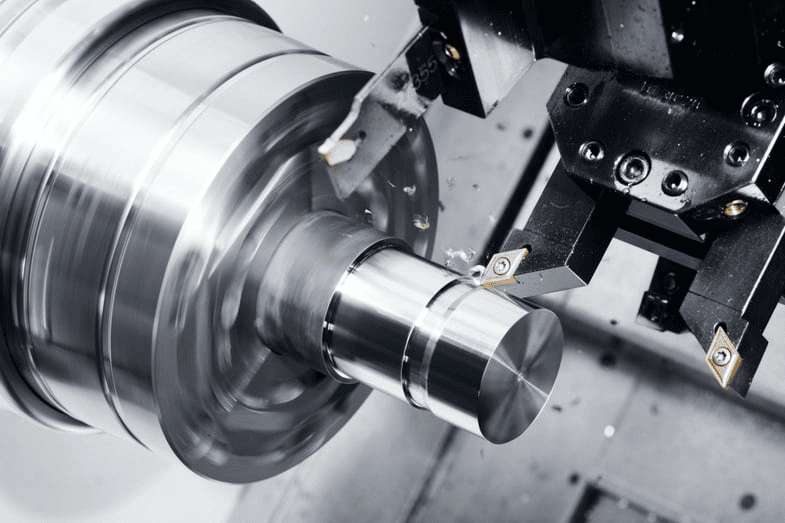

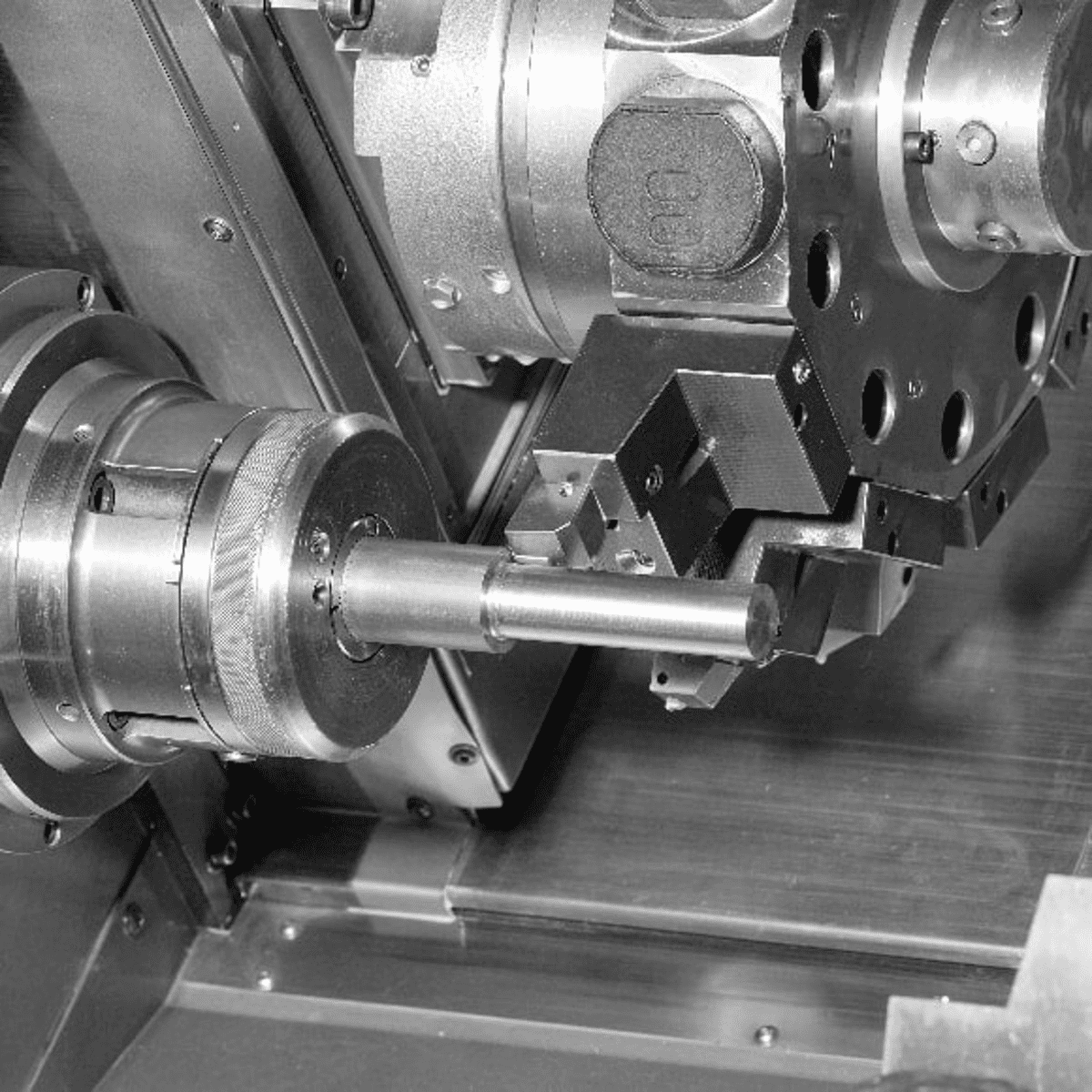

How CNC Milling Works?

CNC turning is a subtractive manufacturing process that utilizes computer-controlled lathes to shape materials into precise cylindrical parts. The process begins with designing the part using CAD software, which is then converted into machine instructions through CAM software. During setup, the appropriate cutting tools are installed, and the cylindrical workpiece is securely held in the machine’s chuck, which rotates the material for shaping.

As the machine operates, the workpiece spins at high speeds while the cutting tools move along various axes to carve, cut, and shape the material based on the programmed design. Common operations like facing, threading, knurling, and drilling are performed, often with coolant applied to prevent overheating and clear away debris. After machining, the part may undergo finishing processes such as sanding or polishing, followed by a thorough inspection to ensure it meets the required dimensions and tolerances.

Advantages

Advantages of CNC Turning

CNC turning offers numerous advantages, making it a preferred choice for manufacturing precise cylindrical parts. Below are the key benefits:

- Precision and Accuracy: :CNC machines achieve tight tolerances, essential for components that must fit perfectly into complex assemblies.

- Efficiency: Once programmed and set up, CNC turning machines quickly produce parts with consistent quality, reducing production time and requiring minimal supervision.

- Flexibility: The ability to easily reprogram machines for different designs enhances adaptability to changing production needs, improving operational responsiveness.

- Repeatability:: Automated processes ensure that each part is identical, even in large production runs, ensuring consistent quality in mass production.

- Reduced Labor Costs::Automation minimizes manual intervention, lowering labor costs and reducing human error, enhancing cost-effectiveness and efficiency.

- Material Versatility CNC turning works with a wide range of materials, from metals to plastics and composites, accommodating various manufacturing needs.

Applications

Applications of CNC Turning

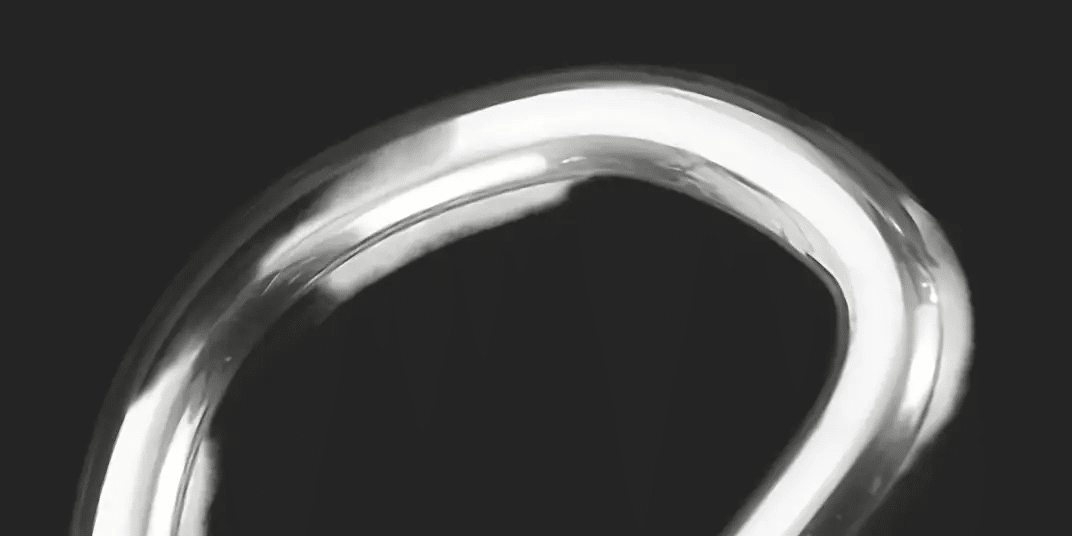

As a leading manufacturer of precision turned parts, Lewei Precision uses CNC turning to create a wide range of components where accuracy and proper fit are essential. Here’s an overview of typical parts produced through this process:

- Shafts: connect pipes, pumps, or valves, and require precise machining to ensure a tight fit and prevent leaks.

- Electronics Parts: Critical in producing components like connectors and pins in electronic devices, where precise measurements are necessary for functionality and compact assembly.

- Busing's and sleeves: offer smooth surfaces for other parts to slide or rotate against, requiring exact internal diameters and flawless finishes.

- Pins: are small yet critical for aligning or securing components, often needing precise dimensions to ensure a tight fit.

- Knobs and Dials: serve as user interface elements for machinery and electronics, where accurate dimensions and aesthetic appeal improve functionality and usability.

Preguntas frecuentes sobre el mecanizado CNC

How does Lewei Precision ensure precision in CNC turned parts?

We use high-precision CNC lathes and advanced measurement tools to ensure tight tolerances and consistent quality throughout the turning process.

Can you handle both small and large quantities for CNC turning?

We focus on optimizing designs for manufacturability, minimizing tool wear, and using efficient turning strategies to reduce both production time and material waste.

How does Lewei Precision reduce costs in CNC turning?

We focus on optimizing designs for manufacturability, minimizing tool wear, and using efficient turning strategies to reduce both production time and material waste.

Does Lewei offer assistance with CNC turning designs?

Yes, our team provides Design for Manufacturability (DFM) advice to help ensure your design is optimized for the CNC turning process.