Custom CNC Milling Services Online

- T1 sample as fast as 2 weeks

- Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards

- Fast, reliable production with high-quality results every time

Custom CNC Milling Services for Precision Parts

CNC Machining Solutions

Creación rápida de prototipos

Speed up product development with our rapid CNC machining services. We provide fast turnaround times and specialize in producing high-quality prototypes and mold tooling, streamlining your design validation process.

Custom Production Solutions for Any Volume

From small batches to large-scale production, we cater to both. With precise tolerance controls and extensive capabilities, we adjust to your volume needs while maintaining exceptional quality.

CNC Milling Materials

At Lewei Precision, our CNC milling services for both plastic and metal materials provide a wide variety of options, ensuring precision and long-lasting durability. This extensive selection gives our clients the flexibility to choose the best material for their specific projects, enhancing product quality and performance.

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Estaño Bronce

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloy

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

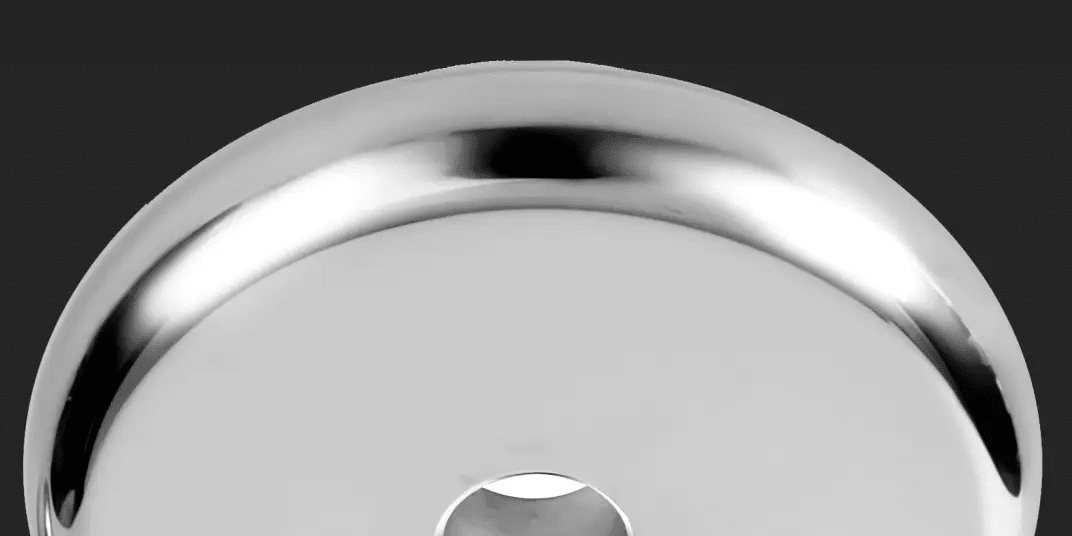

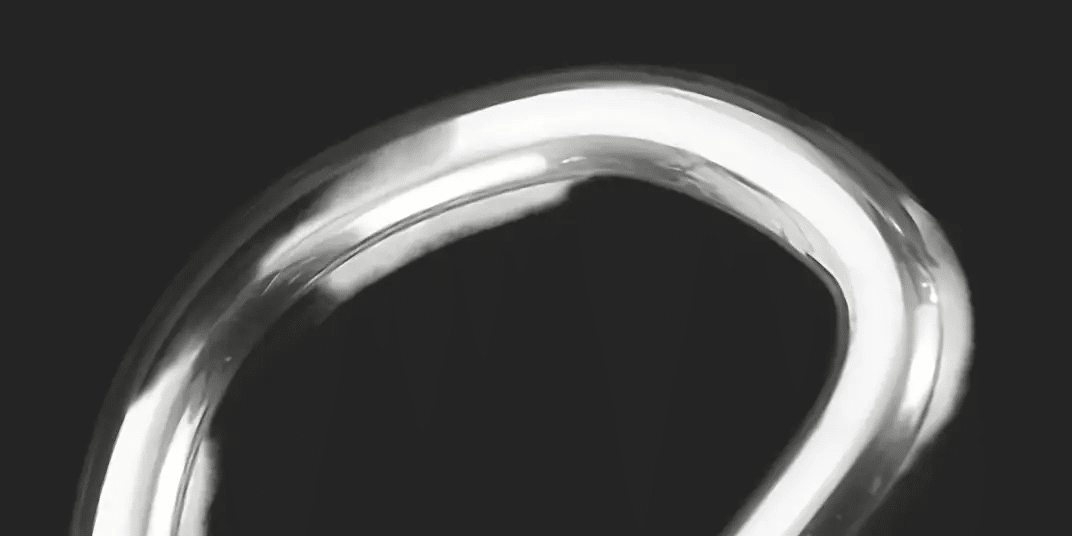

CNC Milling Surface Finishes

Enhance the appearance of your custom CNC milled parts with our high-quality surface finishing services. We help eliminate aesthetic imperfections while also providing added protection, resistance, and strength to your parts through superior surface finishes

Tolerances for CNC Milling

CNC Milling Type | Tamaño máximo de la pieza | Tamaño mínimo de la pieza |

|---|---|---|

3-Axis | 1000 x 500 x 500 mm | 5 x 5 x 5 mm |

4-Axis | 1000 x 500 x 500 mm | 5 x 5 x 5 mm |

5-Axis | 4000 x 1500 x 600 mm | 5 x 5 x 5 mm |

CNC Milling Design Guidelines Recommended Size

| Características | Descripción |

|---|---|

| Radios | – Sharp internal corners become rounded (radii). – Drill depth: ≤ 12 × drill diameter. – End mill depth: ≤ 10 × tool diameter. |

| Threads & Tapped Holes | – Diameter Φ 1.5–5 mm → Depth = 3 × diameter. – Diameter ≥ 5 mm → Depth = 4–6 × diameter. – Lewei Precision can produce threads of any size/specification as required. |

| Socava | – Square profiles – Full radius – Dovetail profiles |

| Texto | – CNC Milling: Minimum width = 0.5 mm, depth = 0.1 mm. – CNC Turning: Text created using laser marking. – Lewei Precision offers CNC engraving or laser engraving as per customer requirement. |

Comience su proyecto de mecanizado CNC

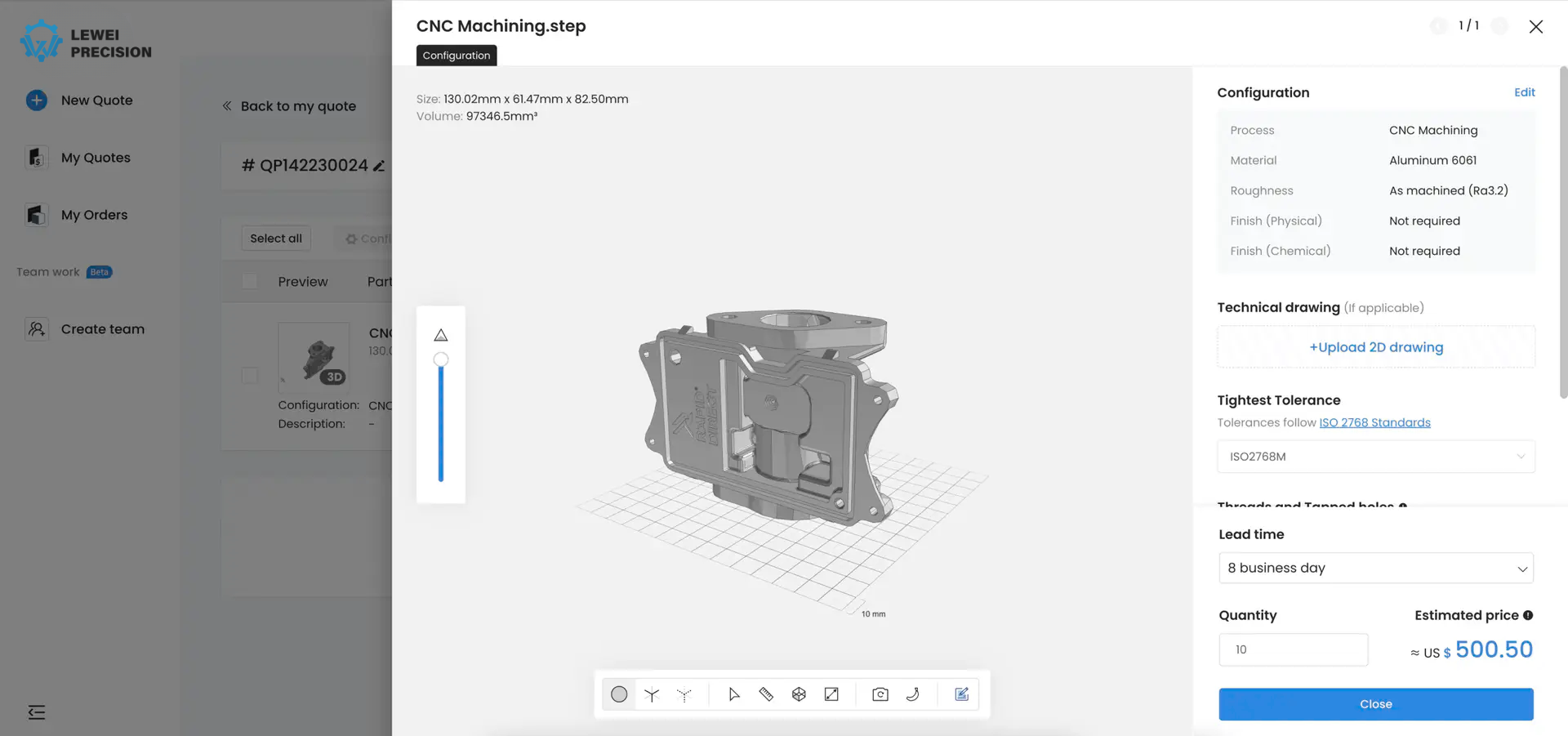

Start your project with our easy-to-use platform for CNC parts online quoting. Upload a CAD file to receive instant quotes, lead times, and DFM details for your CNC components. Specializing in CNC machining for metals and plastics, we offer adaptive production and shipping solutions to align with your product development needs.

With Lewei Precision’s online CNC milling service, you’re not just investing in advanced machinery. You’re assured of exceptional precision, on-time delivery, and the expertise of experienced professionals dedicated to meeting all your custom CNC milling requirements.

Choose Us

Piezas de alta calidad

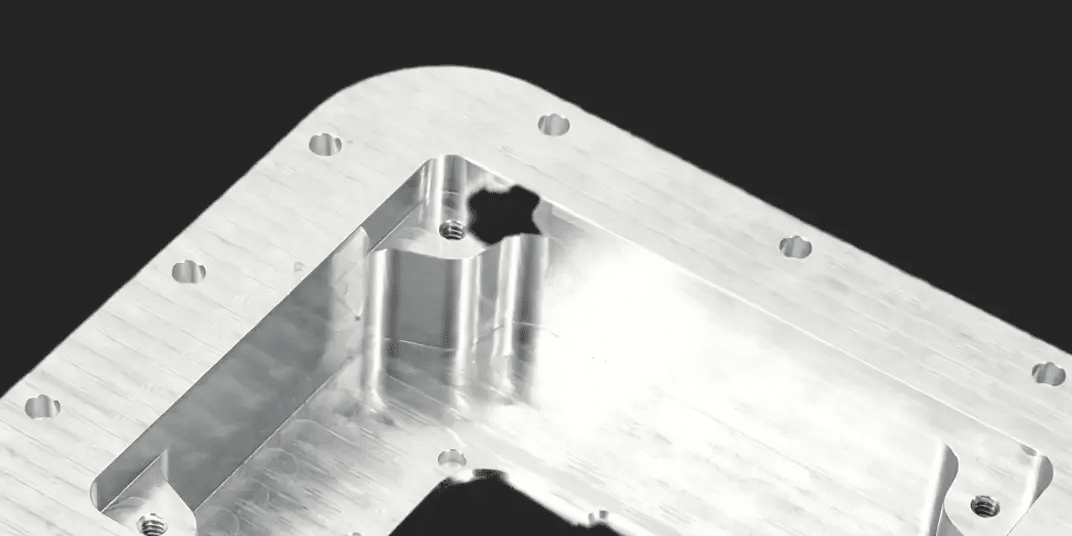

Experience unmatched precision in every project. Our advanced milling processes achieve tight tolerances as narrow as ±0.01mm, ensuring seamless assembly and optimal operational performance.

Speed up your production process with Lewei Precision. Our advanced workshops and cutting-edge machinery ensure rapid turnaround times, enabling businesses to stay on track and meet crucial deadlines efficiently.

Wherever and whenever you need it, navigate your CNC milling projects with assurance. Our experienced specialists provide expert guidance throughout, ensuring optimal design and superior output quality at every stage.

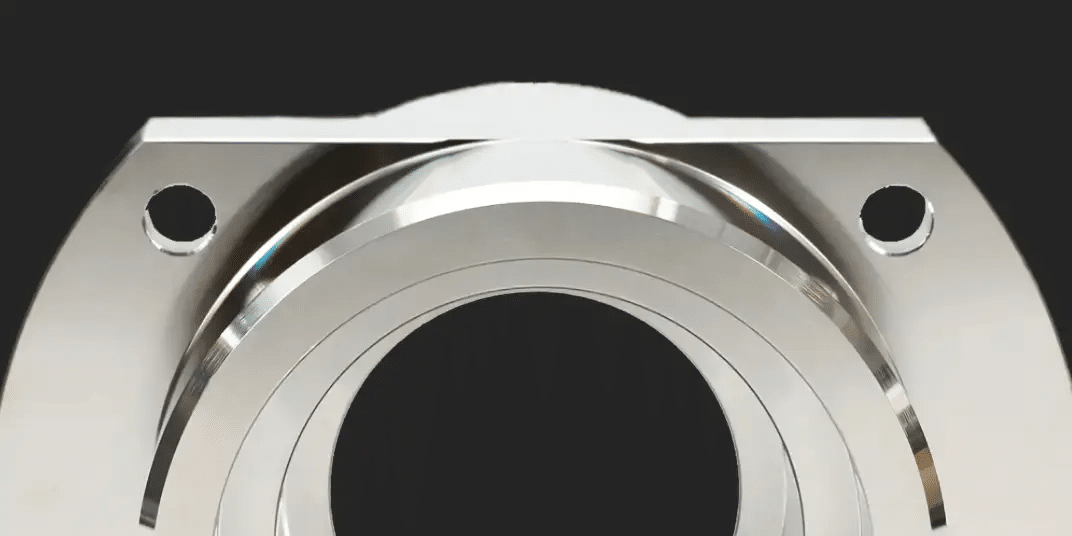

How CNC Milling Works?

CNC milling is a highly precise manufacturing process that removes material from a workpiece using rotating cutting tools. The process starts with a digital design, typically created in CAD software, which is then converted into a CNC program to guide the machine. The workpiece is securely fixed to the machine’s table, and the cutting tool rotates at high speeds, following the programmed path to shape the material into the desired form.

CNC milling can create intricate features such as slots, holes, and contours with high precision. Three-axis milling moves the tool along the X, Y, and Z axes, while four-axis milling introduces rotation along one axis. Five-axis milling allows rotation along two axes, enabling even more complex designs. This flexibility makes CNC milling indispensable across various industries, including aerospace, automotive, and medical device manufacturing.

Advantages

Advantages of CNC Milling

CNC milling provides a range of benefits, ensuring efficient, high-quality production.

- High Accuracy: CNC milling machines offer tight tolerances, ensuring high precision and consistency in every part.

- Complex Design Creation: With multi-axis movement, CNC milling can craft intricate shapes and complex features that are challenging to achieve manually.

- Enhanced Efficiency: Automated processes allow for continuous production, reducing lead times and increasing productivity by minimizing downtime.

- Material Flexibility: CNC milling works with various materials, including metals, plastics, and composites, making it adaptable for numerous applications.

- Consistent Reproduction: Once a design is programmed, the machine can replicate parts with perfect consistency, reducing human error.

- Speed:Though initial setup costs are high, the efficiency and precision of CNC milling reduce overall production costs, particularly for large runs.

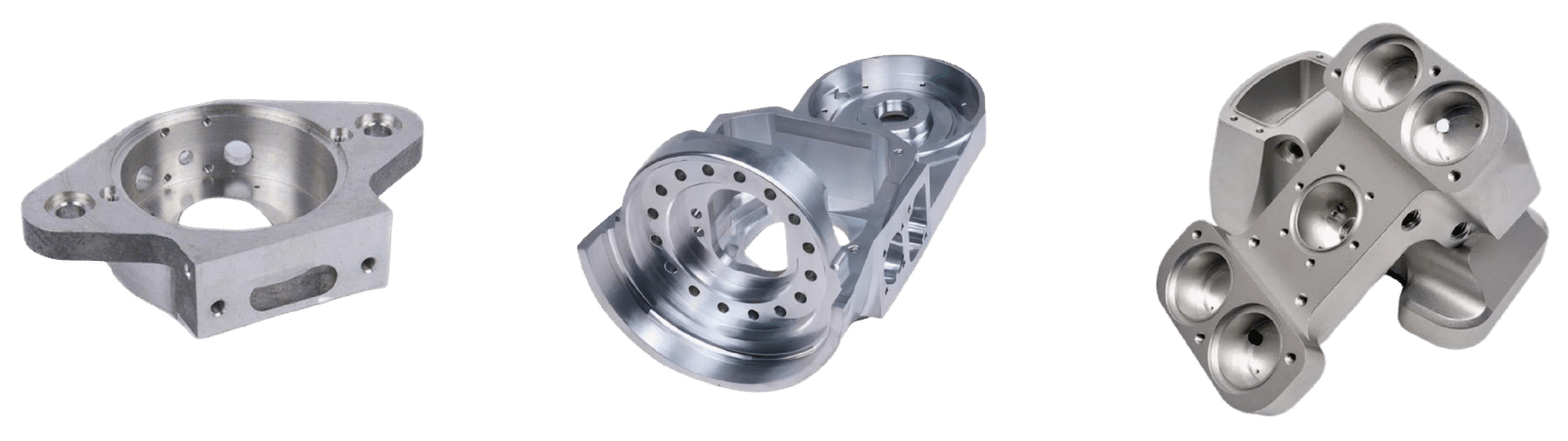

Applications

Applications of CNC Milling

CNC milling is widely utilized in various industries to produce high-precision parts and components:

- Engine Parts:Essential for manufacturing engine blocks, cylinder heads, and pistons, ensuring durability and performance in automotive and aerospace sectors.

- Gear Components: Critical for producing gears, splines, and shafts with tight tolerances, widely used in machinery and automotive systems.

- Medical Devices:Used to create highly accurate implants, such as hip joints, dental implants, and surgical screws for the healthcare industry.

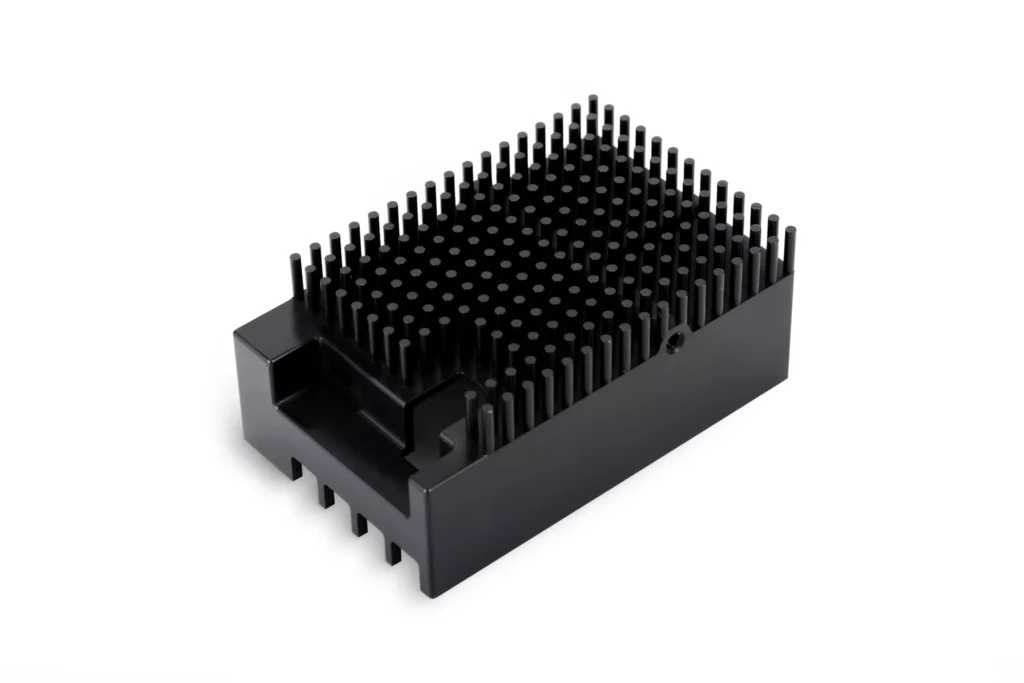

- Electronic Enclosures:Produces housings for electronic devices, offering a secure fit and protection for sensitive circuit boards.

- Custom Prototypes: Enables rapid prototyping for design testing and iteration, allowing designers to refine their products before mass production.

- Tooling and Dies: Key for manufacturing molds, dies, and cutting tools that are used in various production processes.

Preguntas frecuentes sobre el mecanizado CNC

What are the lead times for CNC milling projects at Lewei Precision?

Lead times range from 1-3 weeks for prototypes and 3-6 weeks for larger production runs, depending on complexity.

How does Lewei Precision ensure the quality of CNC-milled parts?

We use precise machinery, tight tolerances, and advanced inspection tools, including CMMs, to ensure each part meets the highest quality standards.

Can you handle both small and large production runs for CNC milling?

Yes, we handle both small-batch prototypes and large-scale production runs with consistent quality and precision.

Does Lewei offer design assistance for CNC milling projects?

your designs for the milling process, ensuring smoother production.