If you’re looking to reduce production waste in your plastic manufacturing, you’ve likely come across the debate: extrusion vs injection molding. Both are popular shaping methods, but which truly keeps waste to a minimum? And how do you decide which fits your products best?

Maybe you produce plastic tubing or large sheets—common extrusion products. Or perhaps you make intricate parts for automotive, household, or medical devices—often injection molded. When minimizing leftover material is your goal, understanding how these processes manage waste is key.

CNC Lewei is here to simplify it for you: extrusion delivers continuous production with fewer scraps, while injection molding produces precise parts with minimal finishing waste. The right choice depends on your product’s shape, volume, and complexity. Let’s explore how each method works, typical waste points, real-world uses, and tips to cut leftover material.

Extrusion vs Injection Molding: The Basics

Extrusión pushes heated plastic through a shaped die to form continuous profiles like pipes or sheets.

Injection molding injects molten plastic into a mold cavity to form solid, often detailed parts.

Comparing them for waste minimization means looking at product design, scrap handling, and reuse potential.

Continuous Production with Extrusion

Extrusion’s strength is nonstop output of uniform shapes. Feed pellets in, and long lengths of consistent profiles come out—greatly reducing trim waste for tubes, rods, and films.

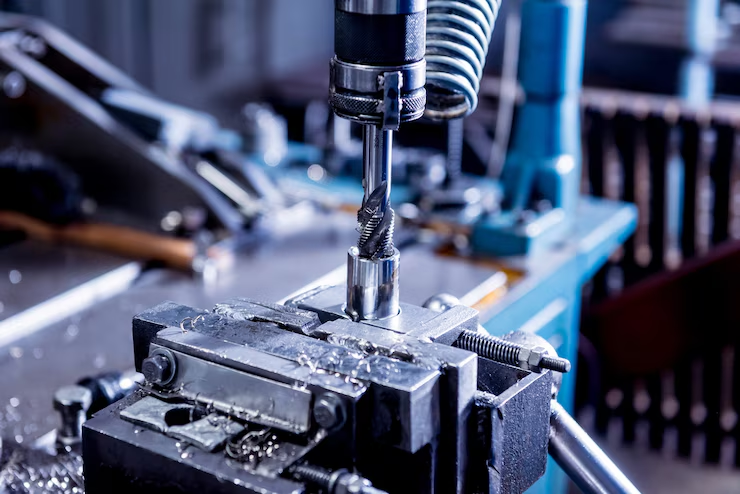

Precision Parts with Injection Molding

Injection molding shines for complex, high-accuracy parts. The mold cavity produces minimal leftover flash or sprue. For tight tolerances and intricate designs, this process keeps rework and scrap low.

Material Reusability

Both processes reclaim scrap, but differently:

- Extrusión scraps usually go directly back into the hopper, simplifying recycling.

- Injection molding sprues and runners require additional processing before reuse.

Mastering regrind techniques helps cut costs but needs consistent material quality and monitoring.

How Extrusion Works

Extrusion shapes plastic by forcing it through a die opening, setting the product’s cross-section. Think plastic pipes, window frames, or packaging film.

Process steps:

- Plastic pellets enter a hopper.

- A rotating screw pushes pellets through a heated barrel, melting them.

- Molten plastic exits the die in the desired shape.

- Cooling systems solidify the extruded profile.

- The continuous product is cut or wound onto spools.

Materials: Polyethylene (PE), polypropylene (PP), PVC.

Where Waste Happens in Extrusion

- Start-Up Purge: Clearing old resin or color before production.

- Edge Trim: Trimming sheet or film edges.

- Defective Sections: Discarding lumps or inconsistencies.

Good news: extrusion scrap is often uniform and easy to reprocess, reducing total waste. Contamination or mixed plastics require caution to maintain quality.

Injection Molding Explained

Injection molding produces solid, detailed parts by injecting molten plastic into molds.

Process steps:

- Plastic pellets melt in a heated barrel.

- Molten plastic is forced into the mold under pressure.

- Part cools and solidifies inside the mold.

- Ejector pushes out the finished part.

Tip: High-quality steel or aluminum molds help reduce flash and defects, minimizing waste.

Where Waste Happens in Injection Molding

- Sprue and Runner System: Excess plastic channels that must be trimmed.

- Defects: Misaligned molds or incorrect pressures cause rejects.

- Material Purge: Needed when changing colors or materials.

- Trial Runs: Testing new molds generates short-term scrap.

Regrinding sprues and runners can reduce waste, but watch polymer degradation.

Industry Applications

| Industry | Extrusion Examples | Injection Molding Examples |

|---|---|---|

| Construction | Window frames, PVC pipes | Fasteners, specialized hardware |

| Automoción | Door seals, hoses | Dashboards, clips, engine parts |

| Packaging | Plastic wrap, sheets | Caps, closures, handles |

| Consumer Goods | Tubes, rods | Toys, electronics cases, precision parts |

| Medical | IV tubing, catheters | Syringes, surgical components |

Quick Comparison Table

| Aspect | Extrusión | Moldeo por inyección |

|---|---|---|

| Typical Products | Pipes, tubing, sheets, profiles | Complex shapes, detailed parts |

| Scrap Sources | Start-up purge, edge trim, defects | Sprues, runners, purges, rejects |

| Regrind Potential | High if uncontaminated | Good but watch polymer degradation |

| Production Mode | Continuous output | Cyclical (per mold shot) |

| Waste Minimization | Easy in-line recycling | Controlled by mold & regrind use |

Conclusion

In the extrusion vs injection molding debate, waste reduction depends on your product’s shape, volume, and recycling approach. Extrusion excels in continuous profiles with minimal leftover ends. Injection molding suits precise, complex parts with efficient sprue regrind.

Both benefit from strong recycling programs, optimized machine settings, and quality molds. Often, combining both processes across product lines yields the best overall efficiency.

FAQs

Q: Do I need special equipment to recycle scrap?

A: A standard granulator or shredder usually suffices, provided scrap is clean and consistent.

Q: Does recycled plastic degrade?

A: Yes, repeated heating can shorten polymer chains. Mixing virgin with regrind maintains quality.

Q: Can one facility run both processes?

A: Absolutely. Many do, using extrusion for profiles and injection molding for complex parts, recycling scrap where possible.

Q: Which is better for biodegradable plastics?

A: Both can process biodegradable resins, but settings differ—consult your resin supplier.

For expert plastic manufacturing solutions and waste reduction strategies, contact CNC Lewei your partner in advanced, sustainable production.