Custom Sheet Metal Fabrication Services

Submit your design today to receive an instant quote for both sheet metal prototypes and production-grade parts.

- We are proudly ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 certified, ensuring the highest quality standards.

- Choose from over 20 materials and 10+ finish alternatives.

- Get top-tier quality with a 3-day lead time.

Our Sheet Metal Bending Services

Bending involves applying force to a thin metal sheet to form it into various shapes such as U, V, or channel configurations. We can work with materials of varying thicknesses to achieve the precise geometry you require.

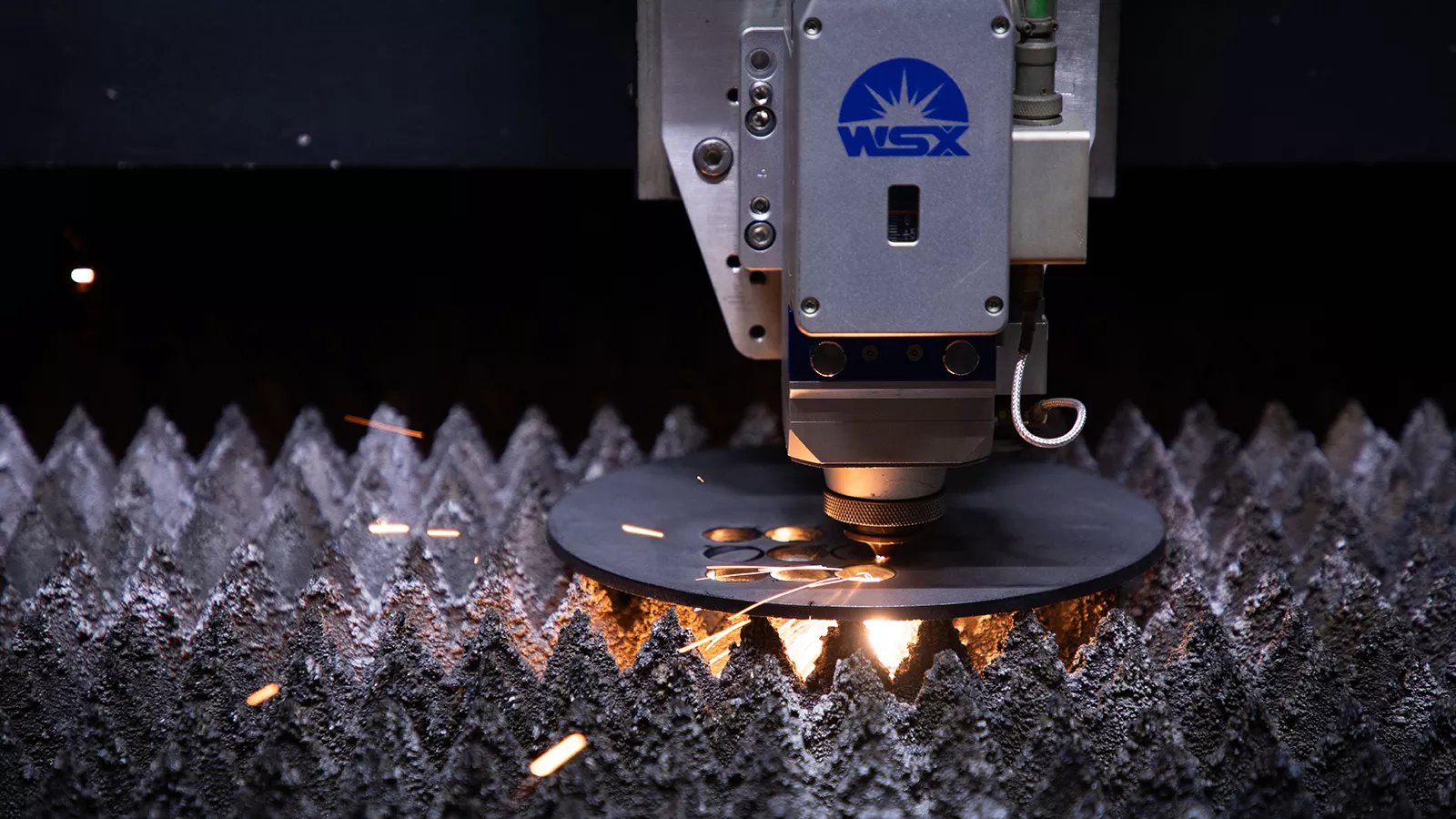

Laser cutting utilizes a focused laser beam to cut, etch, or engrave materials, melting or vaporizing them to create precise edges and intricate patterns according to design specifications.

Bending applies force to a thin metal sheet, shaping it into various forms such as U, V, or channel shapes. The metal thickness can vary based on the requirements.

Welding is a technique that joins two or more metal pieces using heat, pressure, or a combination of both to create a strong, lasting bond. This process requires both skill and precision to produce durable, robust metal structures.

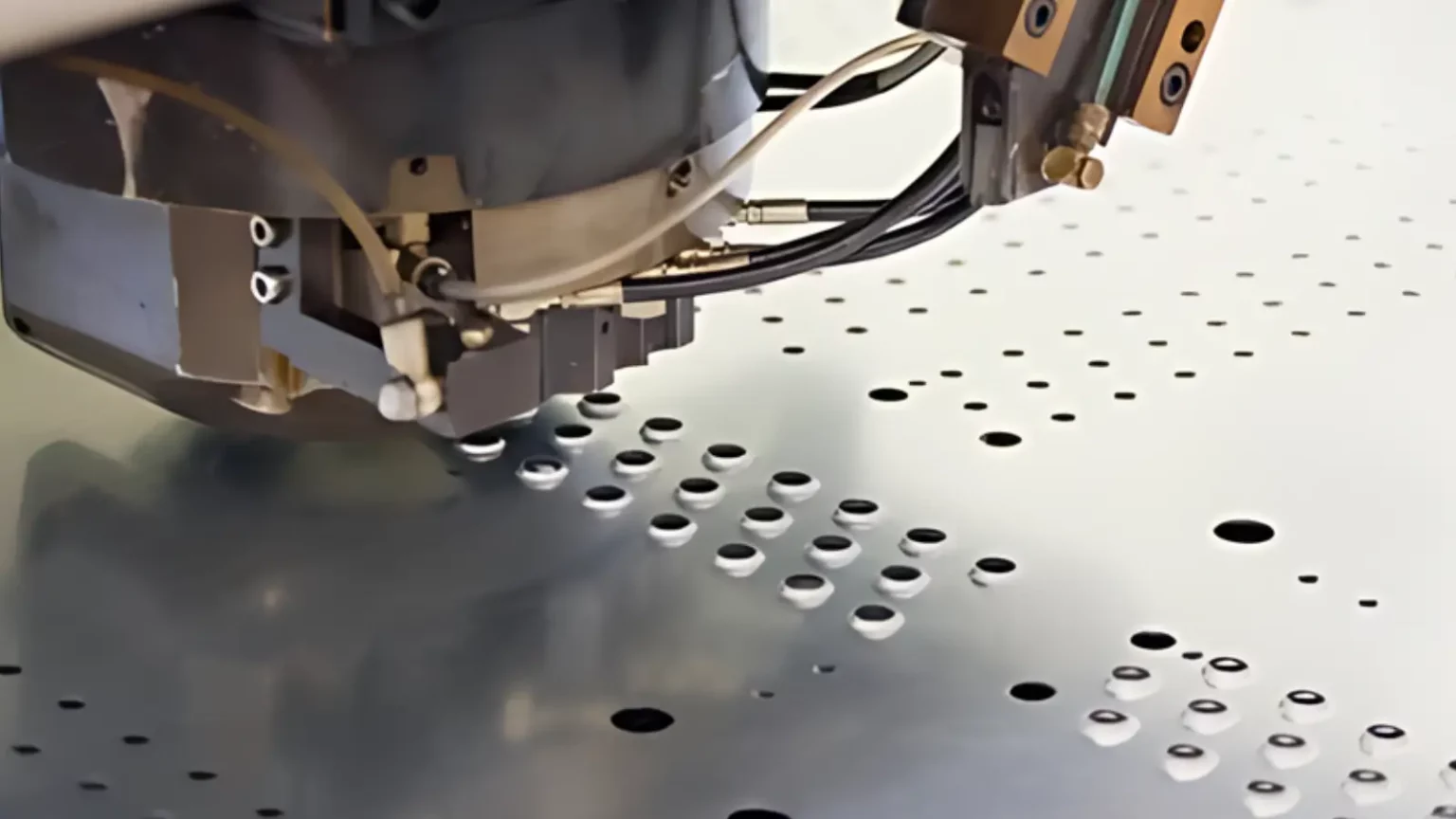

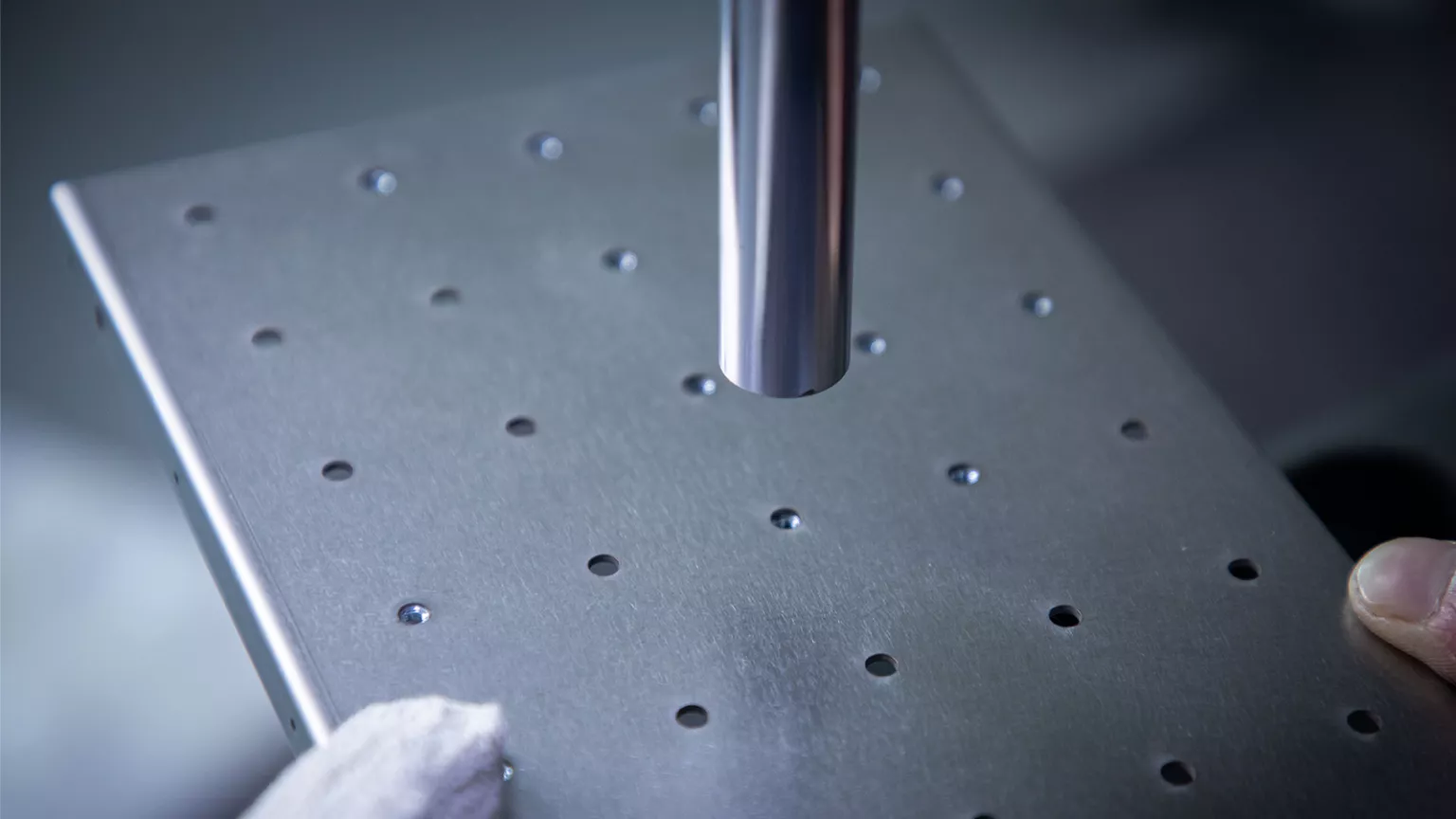

Punching involves using a punch tool to create holes or shapes by forcing it through a die, shearing the metal for precise and clean cuts. This method ensures accurate results in fabrication.

Riveting is a semi-permanent method of joining sheet metal parts using mechanical fasteners (rivets). It’s a faster and more cost-effective solution than welding.

Stamping uses dies and presses to shape flat metal sheets into various forms, producing intricate, three-dimensional designs through cold-forming methods.

How Lewei Precision Sheet Metal Fabrication Works

With our extensive network of sheet metal shops in China, we have the capability to handle any project, from intricate prototypes to complete assemblies. We begin with your CAD designs, converting them into machine code, and then our skilled team takes over to cut, bend, and shape the metal to perfection using welding, riveting, and other techniques.

Additionally, we offer a variety of finishing options to ensure each part not only performs optimally but also has a polished, professional appearance. Whether it’s a single unit or a large-scale production run, we ensure high-quality results delivered on time.

Sheet Metal Materials

Select from a diverse range of sheet metal materials such as aluminum, stainless steel, and brass. Each material is carefully selected for its unique properties, enabling us to recommend the most suitable option based on the specific requirements and applications of your project.

As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Copper is highly conductive and malleable, making it a top choice for electrical wiring and plumbing. Its natural antibacterial properties also make it ideal for medical applications, while its aesthetic appeal suits decorative items and artwork.

Red-orange

Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish

$$$

About 5 business days

Bronze, an alloy of copper and tin, is known for its durability and resistance to corrosion. It’s widely used in marine applications, sculptures, and bearings, thanks to its strength and ability to withstand harsh environments.

Metallic brown

Tin Bronze

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish

About 5 business days

Steel is a strong and versatile material, widely used in construction and manufacturing. Its high tensile strength makes it suitable for structural components, while various Subtypes enhance its properties for specialized applications, like tools and machinery.

Silver Grey

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

As machined, Electroplating, Passivation, Powder coating

About 7 business days

Stainless steel is resistant to rust and staining, making it perfect for kitchen appliances and medical equipment. Its strength and aesthetic appeal also make it a popular choice for architectural designs and automotive parts.

Silver Grey

Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

As machined, Electroplating, Passivation, Powder coating

ABout 7 business days

Magnesium is lightweight yet strong, often used in aerospace and automotive applications where reducing weight is critical. Its machinability allows for complex shapes, and it’s also utilized in various electronic devices for its excellent conductivity.

White-silver

Magnesium Alloy AZ31B, AZ91D

As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis

ABout 8 business days

Titanium is incredibly strong and lightweight, making it ideal for aerospace and medical implants. Its resistance to corrosion and biocompatibility enhance its use in demanding environments, while its high strength-to-weight ratio suits various industrial applications.

Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish

ABout 8 business days

Surface Finishing Options for Metal Parts

Enhance the durability and appearance of your custom metal parts with our range of surface finishing options. If you require a specific finish not listed, simply select “Other” and let us know your exact needs.

Provides a durable and high-quality finish that protects against corrosion, scratches, and fading. Available in a wide variety of colors and textures.

A process that increases corrosion resistance and provides a decorative, durable finish to aluminum parts, while also enhancing the material’s surface hardness

Creates a uniform texture on the surface of the metal, giving it a matte, satin look that’s ideal for architectural and interior applications.

Involves applying a thin layer of metal (such as gold, chrome, or nickel) to the surface of a metal part for enhanced protection, appearance, and conductivity.

Achieves a shiny, smooth surface for metal parts, enhancing aesthetic appeal and reducing surface roughness. Ideal for parts requiring a reflective, clean finish.

Involves coating metal, typically steel or iron, with a layer of zinc to prevent corrosion. This finish is ideal for outdoor or industrial applications where long-term durability is required.

Lewei Precision Solutions

Whether you’re creating a small batch of custom parts or scaling up for high-volume production, Lewei Precision services offer the flexibility you need.

Receive high-quality sheet metal prototypes in just 3 business days. With no minimum order quantity, our fast and cost-effective service accelerates design validation and helps streamline product iterations for quicker development.

- Lead Time: 3-7 days

- Quantity: 1-50 pcs

Perfect for transitioning to full-scale production or handling small batch runs, our low-volume sheet metal fabrication service adapts to your timeline, ensuring reliable, on-time delivery and exceptional quality.

- Lead Time: 1-3 weeks

- Quantity: 50-5000 pcs

Our comprehensive, all-in-one service delivers fast, precise high-volume sheet metal fabrication, including finishing and assembly. We meet your specifications while optimizing time and cost for large-scale production runs.

- Lead Time: 4-8 weeks

- Quantity: 5,000+ pcs

Sheet Metal Fabrication Capabilities at Lewei

Our CNC machines operate with precision tolerances that meet industry standards, ensuring that every part is consistently accurate and fits perfectly with other components.

Specification | Description |

General Tolerances | Metals : ISO 2768-c |

Cutting Feature | ± .00787” |

Bend Angle | ± 1.0° |

Bend to Edge | ±0.010″ |

Bend to Hole | ±0.2 mm |

Trusted Sheet Metal Parts, Built to Perfection

At Lewei Precision, quality is our top priority at every stage, from design to production. We apply Design for Manufacturability (DFM) principles to ensure that we understand your specific needs and provide the best solutions for your project. Our advanced capabilities include computer-controlled processes such as laser cutting, bending, punching, welding, stamping, and riveting, all carried out with precision to meet your specifications.

To maintain the highest standards, we employ state-of-the-art inspection tools, including CMM, 2D measuring instruments, XRF analyzers, gauges, micrometers, and calipers. With years of experience and ISO-certified fabrication facilities, we deliver custom sheet metal parts with tight tolerances. Choose Lewei Precision for reliable, accurate, and high-quality sheet metal parts tailored to your project’s needs.

- Certifications: ISO 9001:2015, ISO 13485, ISO 14001, IATF 16949

- Quality Engineers: 30+

- Inspection Equipment: 20+

- Tolerances: 1 inch or less

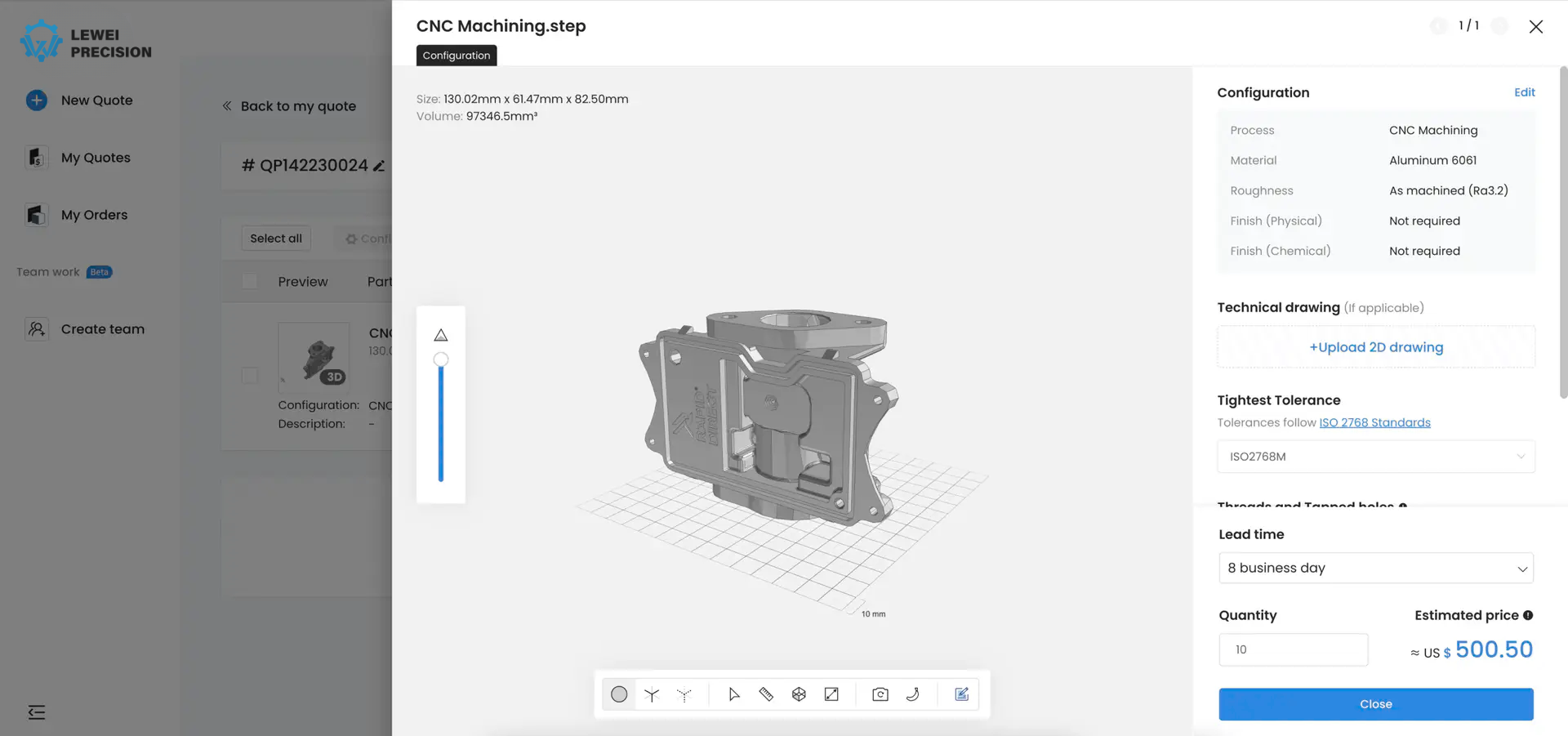

Instant Sheet Metal Quoting with Lewei Precision

Need sheet metal parts quickly? Lewei Precision’s online quoting platform makes it easy to select specs, materials, and finishes in just a few clicks. You can submit designs and place orders anytime, anywhere no need to visit a shop. It’s a fast, efficient, and precise way to get the parts you need on your schedule. Explore our platform today and get started on your next project with ease.

Sheet Metal Fabrication for Diverse Industries

Lewei Precision offers custom, high-precision sheet metal components tailored to various industries. We prioritize quality, durability, and dependable performance, ensuring each part meets the specific needs of your industry.

Why Choose Us

High Quality Parts

We manufacture precision sheet metal parts in ISO-certified machine shops, ensuring strict inspections for dimensional accuracy and optimal functionality. We are committed to addressing your most critical requirements.

We provide lead times as short as 3 days. With unlimited capacity and flexible shipping options, we accelerate your sheet metal projects for timely delivery and a competitive advantage.

Let Lewei Precision’s engineering experts assist with your design challenges. Receive quick, accurate solutions through live chat, with real-time responses to your inquiries.

Lewei Precision Solutions

Whether you’re creating a small batch of custom parts or scaling up for high-volume production, Lewei Precision services offer the flexibility you need.

Advantages

Advantages of Sheet Metal Fabrication

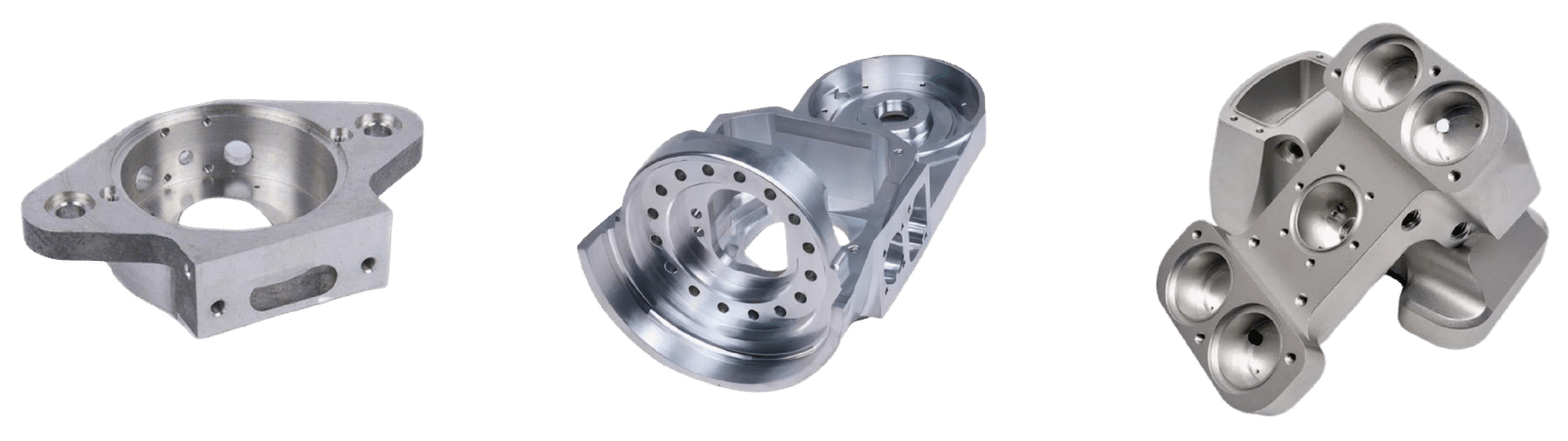

Precision machining offers significant benefits by producing parts with exceptional accuracy.

- High Accuracy: Precision machining tools can produce parts with extremely tight tolerances, ensuring that each piece meets exact specifications. This is crucial for applications requiring intricate details, such as in aerospace and medical devices.

- Consistency: This method offers unmatched consistency in production. Even over large volumes, each part remains identical, reducing the risk of errors and defects in the final product.

- Material Versatility: Precision machining can handle a wide range of materials, from metals to plastics and composites. This flexibility allows manufacturers to choose the ideal material for specific properties like strength, weight, or resistance.

- Complex Geometries: With advanced CNC machines, manufacturers can create complex shapes that would be difficult or impossible to achieve through manual processes. This capability is vital for developing innovative products and components.

- Reduced Waste: Since precision machining is so accurate, it minimizes material wastage. This efficiency not only saves on raw materials but also reduces the overall environmental impact of manufacturing.

- Speed: Modern precision machining techniques are highly automated, leading to faster production times compared to traditional methods. This speed enables quicker turnaround times for projects, keeping pace with market demands.

Applications

Applications of Sheet Metal Fabrication

Sheet metal fabrication produces a diverse range of parts and components, each tailored to meet specific functional and aesthetic requirements:

- Enclosures & Casings: Protects machinery and electronics, providing structural integrity and resistance to heat.

- Brackets & Mounts: Delivers secure support and mounting solutions for various applications.

- Panels & Chassis: Forms the structural framework for vehicles, electronics, and machinery..

- Ductwork & Ventilation: Essential for HVAC systems, ensuring efficient airflow and temperature regulation.

- Custom Shelving & Storage: Provides custom solutions for organizing and securing items in commercial and industrial environments.

- Decorative Elements:Adds aesthetic value to buildings, vehicles, and consumer products.

- Prototypes: Supports the rapid development and testing of new designs and concepts.

CNC Machining FAQs

What materials are available for sheet metal fabrication at Lewei Precision?

Lewei Precision offers a wide range of materials for sheet metal fabrication, including stainless steel, aluminum, brass, copper, and titanium. We also work with plastics and composites.

How do you ensure high precision in sheet metal parts?

We employ advanced manufacturing techniques like laser cutting, CNC machining, and high-precision bending, combined with state-of-the-art inspection tools like CMM, micrometers, and calipers to ensure each part meets exact specifications.

Can you handle both low and high-volume sheet metal production?

Yes, Lewei Precision is equipped to handle both low and high-volume production. Whether you need a small batch of parts for prototyping or large-scale production runs, we can meet your specific needs while maintaining high-quality standards.

How can I submit my design for sheet metal parts?

You can easily submit your designs through our online platform for an instant quote. Simply upload your CAD files, choose your material, and specify any finishing options to get started.