Lewei Precision provides custom automotive prototyping and parts manufacturing services, tailored for automotive product development.

At Lewei Precision, we specialize in the prototyping and production of industry-standard automotive parts. By combining manufacturing expertise with advanced technology, we ensure the delivery of high-quality parts, no matter the complexity. We guarantee durable components that meet your production goals, accelerating the development of your automotive products.

Choose Us

High Quality Parts

Our ISO-certified CNC machining ensures precision and quality. Every part is made to fit perfectly and perform flawlessly with advanced quality control at every step.

Count on us anytime, anywhere for your CNC machining needs. Our specialists provide support to maximize design efficiency and quality.

Prototyping

Prototypes mark the early stages of automotive product development. During this phase, you test designs, implement necessary changes, and select the appropriate materials for your automotive parts.

- Fast proof of functionality

- Innovative models similar to the final component

- Prototypes with production-grade materials

- Design and material iterations in the early stages

Engineering Validation and Testing

Make performance-based iterations quickly and efficiently to ensure prototypes meet standard requirements. At Lewei Precision, we produce functional prototypes, helping identify and mitigate design risks. Multiple iterations may be needed, but this process guarantees that the final prototype meets all functional and performance standards.

- Design optimization and material selection

- Comprehensive design and engineering options

- Functional prototypes with unmatched accuracy

Design Validation and Testing

In this stage, we evaluate and validate part functionality, appearance, and performance using various materials and surface finishing options. At Lewei Precision, we offer a wide selection of materials and finishes tailored to your unique design needs. Parts with aesthetic finishes in this phase maintain full functionality and are ready for market testing.

- Surface finishing optimization and validation

- Functionality and aesthetic assessment

- Quality prototypes for life-cycle testing

Production Validation and Testing

This is the final stage before mass production begins. PVT focuses on preparing your design for full-scale production with advanced quality control and production-grade manufacturing capabilities. At Lewei Precision, we collaborate closely with you to ensure your production goals are met. Your feedback allows us to make final adjustments for optimal manufacturing, and we also assist in setting up the product supply chain.

- Production-grade design changes

- Top-quality precision parts with tight tolerances

- In-depth verification of manufacturing methods

- Agile and efficient low-volume production solutions

Mass Production

After product testing, the next step is mass production of end-use parts. At this stage, fast delivery and precise quality control are crucial. Lewei Precision mass produces your parts using advanced manufacturing equipment, processes, and the expertise of professional engineers.

- High-quality, production-ready components

- Precision machining with tight tolerances

- Unmatched post processing operations

- Comprehensive quality inspection control system

Lewei Precision provides exceptional manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our in-house facility and extensive global manufacturing network, we deliver complex, high-quality parts efficiently.

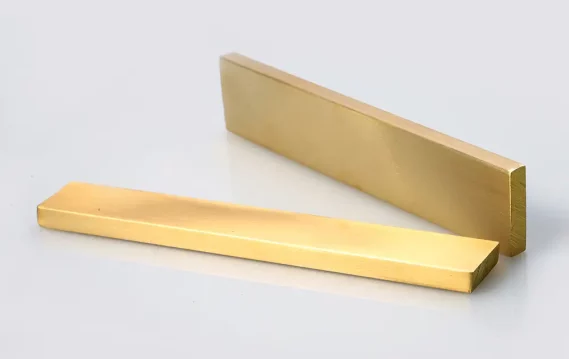

Achieve precise, intricate designs through milling, turning, and post-processing, making it perfect for both complex prototypes and functional metal components.

Quickly produce molded parts and bridge tooling, optimized for high-volume production with consistent quality.

Offers versatility in forming precise metal components, tailored for diverse applications, ensuring both adaptability and accuracy.

Fast and flexible, this method rapidly creates complex geometries from various materials, ideal for innovative designs.

A cost-effective method for producing uniform, long parts from various materials, optimizing production efficiency and material utilization.

Perfect for high-precision metal part manufacturing, this process excels in large volumes, delivering consistent quality across all components.

Ideal for producing high-quality prototypes or end-use parts in small quantities, offering exceptional detail and finish.

Offers unparalleled precision in cutting intricate, hard materials, making it perfect for detailed and complex components.

Materials & Surface Finishes

We offer a diverse range of materials, including metals, plastics, and composites.

At Lewei Precision, we enhance the production rate for a wide variety of automotive components. Common automotive applications we handle include:

- Plastic dash components

- Support for vehicular consumer electronics

- Assembly line components

- Armatures

- Housing and enclosures

- Fixtures

- Aftermarket parts

- Lighting features and lenses