At Lewei Precision, we provide high-quality manufacturing services for custom aerospace prototypes and production parts.

Developing consumer and computer electronic components requires advanced manufacturing processes to speed up product fabrication and reduce development costs. Lewei Precision elevates electronics manufacturing through a blend of experience, technical expertise, and state-of-the-art technology. Our commitment to meeting customer needs ensures the production of well-designed, user-centric electronics prototypes and products.

Choose Us

High Quality Parts

Our ISO-certified CNC machining ensures precision and quality. Every part is made to fit perfectly and perform flawlessly with advanced quality control at every step.

Count on us anytime, anywhere for your CNC machining needs. Our specialists provide support to maximize design efficiency and quality.

Prototyping

- Models similar to final products

- Detailed prototypes for complex geometries

- Rapid material and design iterations

Engineering Validation and Testing

Easily iterate on precise functional prototypes to meet all performance requirements. Our prototypes help identify design risks and mitigate them effectively. Multiple iterations may be needed to ensure the prototypes meet all functional and performance metrics.

- Optimized material properties for custom designs

- Reliable design and engineering support

- Precision parts manufacturing

Design Validation and Testing

Effectively validate the functionality, performance, and appearance of your parts with a variety of material and surface finishing options. This stage ensures you analyze the final look and feel of the aerospace component. Lewei Precision offers a wide selection of mechanical designs, materials, and finishes to meet your specific needs.

- Durable and quality surface finishes

- Performance and appearance validation

- High-quality parts for consumer and market testing

Production Validation and Testing

Prepare your design for full-scale production with advanced manufacturing capabilities and rigorous quality control. Get valuable feedback during the DVT stage to ensure your design meets production goals. Make final adjustments to optimize manufacturing effectiveness.

- Verify functionality of production-ready parts

- Low-volume production tooling

- Verification of manufacturing processes

- Rapid delivery of production-quality parts

Mass Production

Effortlessly transition from product testing to mass production of end-use parts. Lewei Precision ensures the adoption of strict quality standards and rapid delivery of final products. Our team manages the production process, applying engineering expertise and advanced manufacturing techniques. With professional technicians, we guarantee high production yield and quality while reducing costs and lead times.

- Rigorous inspection and quality control

- Secondary operations for enhanced surface finishes

- Tight tolerances on precision machined parts

- High-quality custom end-use parts

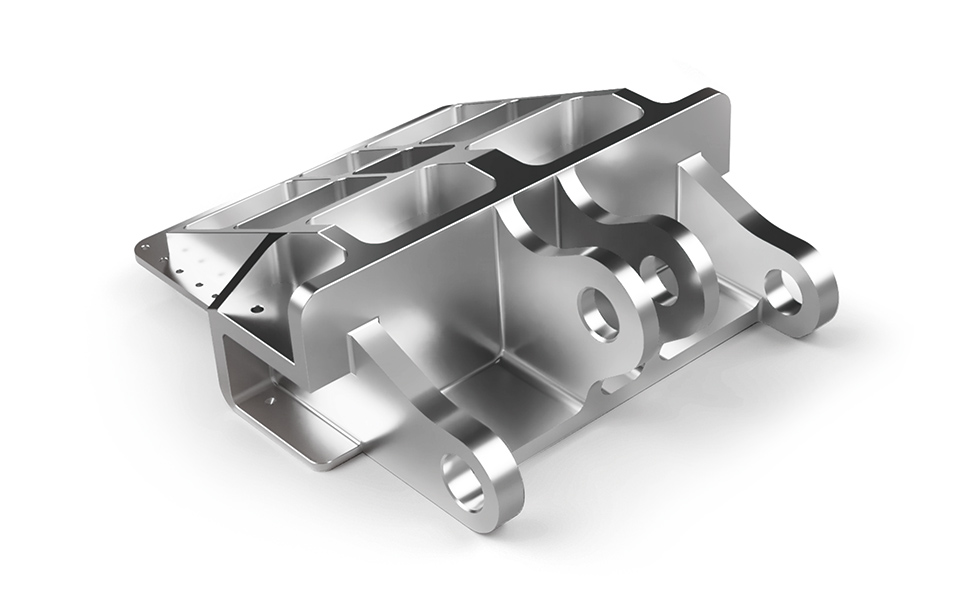

Lewei Precision offers exceptional manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our in-house facility and a vast network of global manufacturing partners, we are equipped to deliver complex, high-quality parts with efficiency and precision.

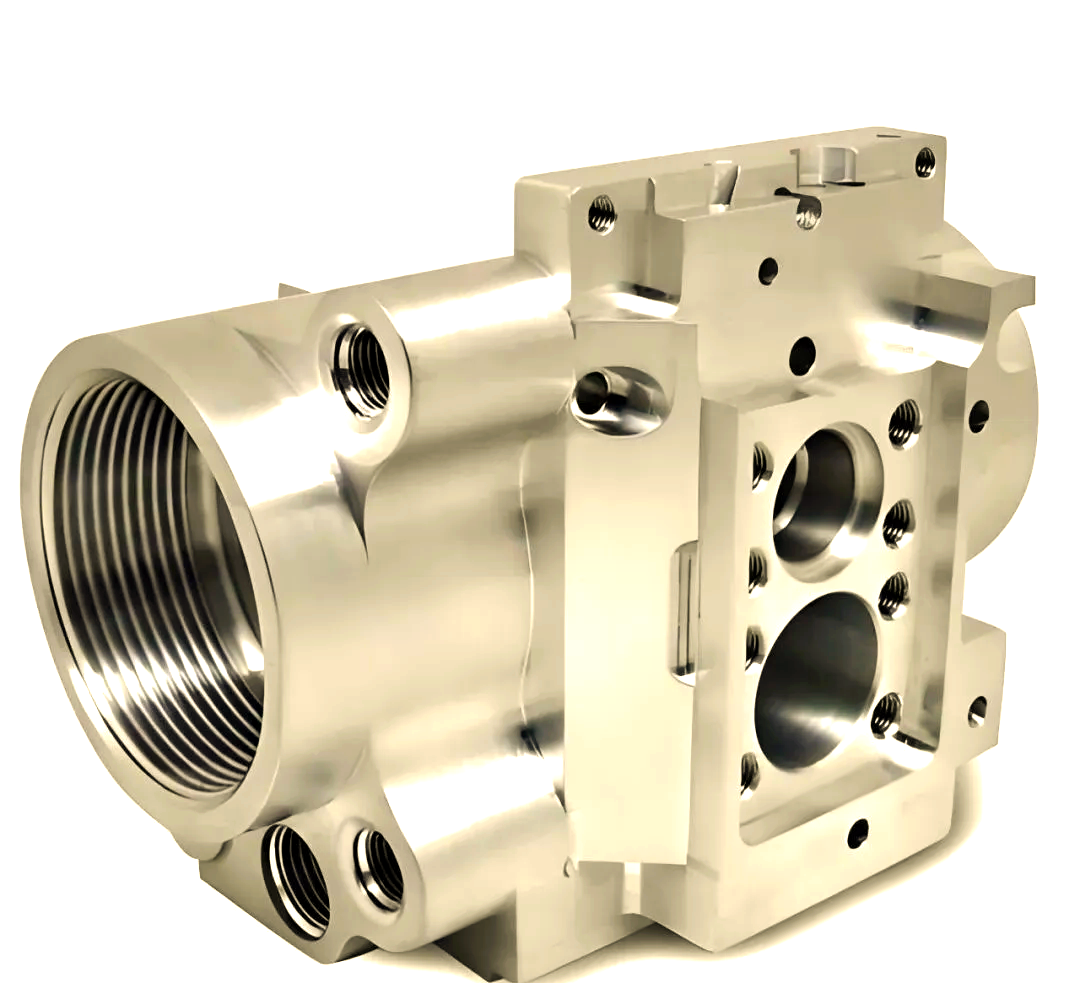

Achieve precise, intricate designs through milling, turning, and post-processing, making it perfect for both complex prototypes and functional metal components.

Quickly produce molded parts and bridge tooling, optimized for high-volume production with consistent quality.

Offers versatility in forming precise metal components, tailored for diverse applications, ensuring both adaptability and accuracy.

Fast and flexible, this method rapidly creates complex geometries from various materials, ideal for innovative designs.

A cost-effective method for producing uniform, long parts from various materials, optimizing production efficiency and material utilization.

Perfect for high-precision metal part manufacturing, this process excels in large volumes, delivering consistent quality across all components.

Ideal for producing high-quality prototypes or end-use parts in small quantities, offering exceptional detail and finish.

Offers unparalleled precision in cutting intricate, hard materials, making it perfect for detailed and complex components.

Materials & Surface Finishes

We offer a diverse and reliable selection of high-quality materials, including a wide range of metals and durable plastics.

We provide high-quality surface finishes that improve part durability and aesthetics, ideal for applications needing smooth or textured surfaces.

Our advanced manufacturing capabilities accelerate the production of various aerospace components for specialized applications. Below are some common aerospace applications:

- Gas and liquid flow components

- Fuel nozzles

- Fit check gauges

- Turbo pumps and manifolds

- Conformal cooling channels

- Custom fixturing

- Heat exchangers

- Rapid tooling, brackets, chassis, and jigs