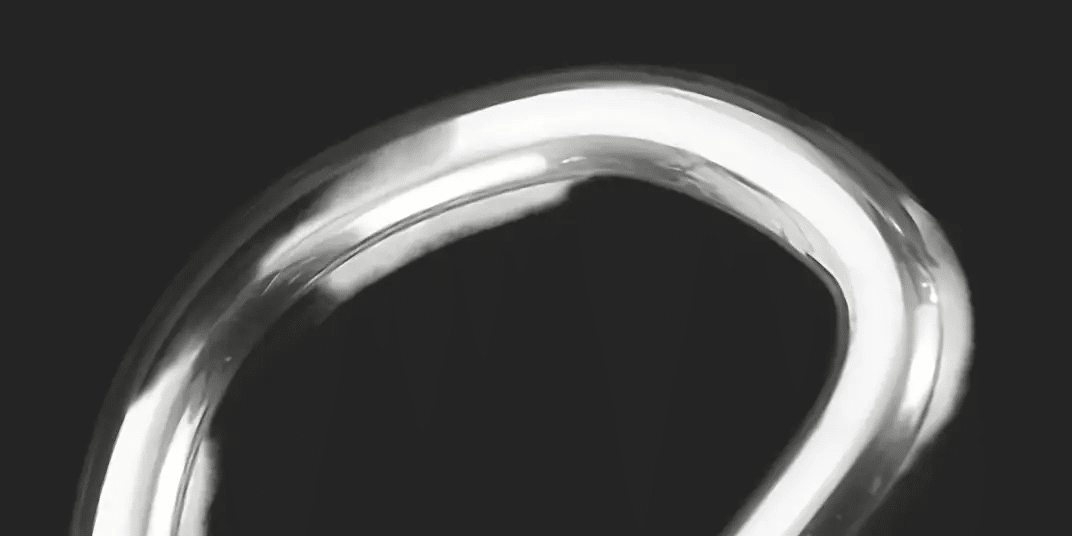

Custom Sheet Metal Bending Services

We offer expert metal bending services, delivering high-precision bends for custom parts that meet your exact specifications, no matter the complexity.

- Ideal for aerospace, automotive, and manufacturing sectors

- International prototype pricing includes tariffs

- Quick-turn prototypes and production parts in days

Our skilled engineers use advanced metal bending technology and strict quality control processes to guarantee that every bent metal part meets the highest standards of precision and durability.

With our advanced CNC bending equipment and efficient workflows, we can deliver your custom bent parts in record time.

Our experts assist you in making the best choices for your project, from selecting materials to choosing the right bending methods, ensuring optimal results with every order.

What is Metal Bending?

Metal bending is a fabrication process that shapes metal by applying mechanical force to achieve a specific angle or form. This method is crucial for manufacturing components with precise angles and curves, making it essential for creating durable and functional parts in various industries.

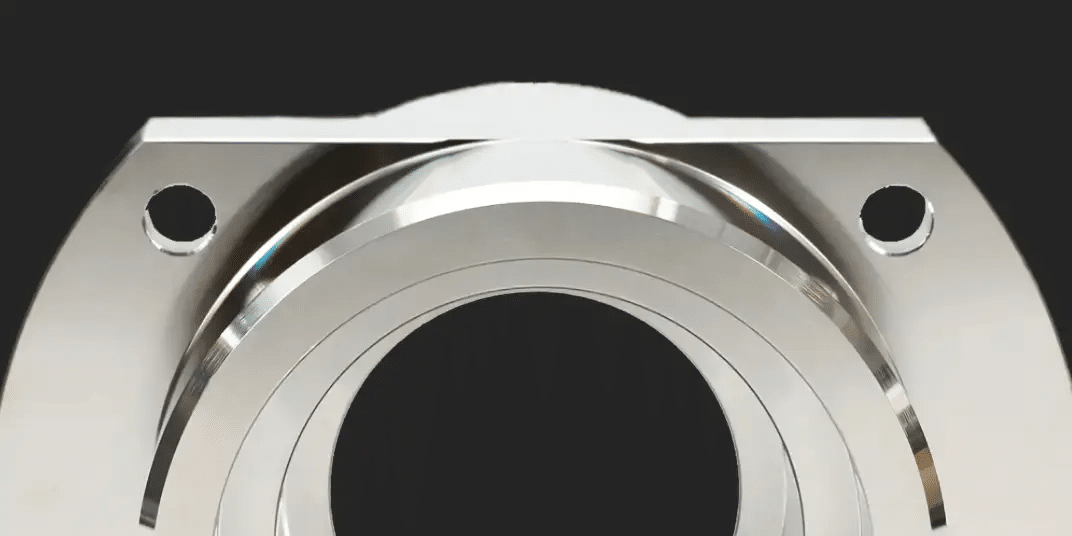

At Lewei Precision, our sheet metal bending services cater to a wide range of client needs, from simple to complex designs. Equipped with advanced electric and hydraulic press brakes, we ensure precise bending even for parts with tight tolerances. Our user-friendly platform allows you to instantly receive quotes by uploading your 3D CAD files, streamlining the transition from design to production. In addition to bending, we offer comprehensive post-processing options, ensuring that the parts are ready for immediate use in prototypes or final products.

How does Metal Bending Work?

Metal bending is a crucial method in metal fabrication that involves deforming metal into a desired shape by applying force, typically using a press brake or similar machine. This process allows for precise forming along a straight line to create shapes such as V, U, or channel bends in sheet metal. The technique can range from manual methods to advanced CNC (Computer Numerical Control) systems, which offer enhanced precision and repeatability.

This metal bending technique is widely used for producing strong, functional parts efficiently. It is commonly employed to create components ranging from small brackets to large architectural features. With the evolution of CNC technology, complex and highly precise bending tasks are now more feasible, offering greater design flexibility and faster production cycles. CNC systems are especially beneficial for mass production, providing minimal variation and ensuring consistent quality across large batches.

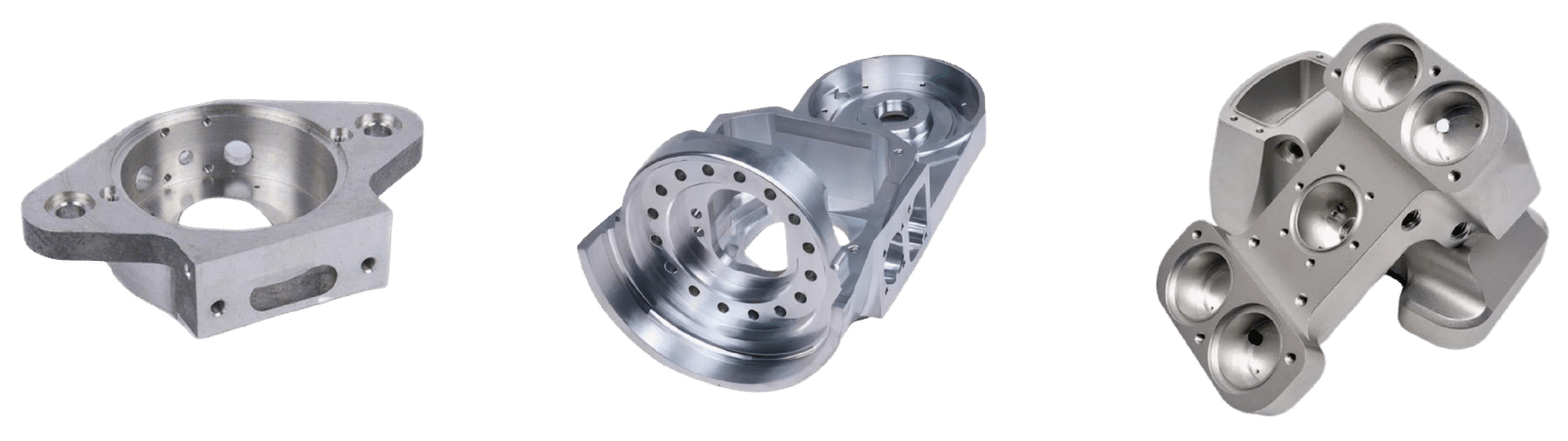

Metal Bending Materials

We offer a variety of sheet metal materials, including aluminum, stainless steel, and brass. Each material is selected for its unique properties, enabling us to recommend the best option for your project’s specific requirements and applications.

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

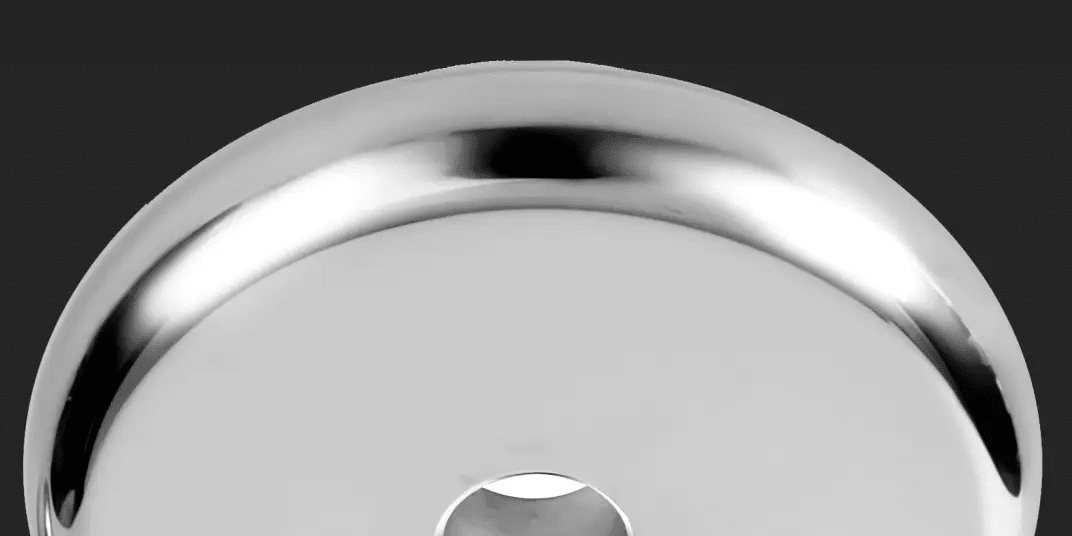

Metal Bending Surface Finish

At Lewei Precision, our surface finishes improve the durability and appearance of bent metal components, ensuring they meet the high standards required across various industries.

Provides a durable, high-quality finish that offers excellent corrosion resistance and can be customized in a variety of colors and textures.

A process that creates a protective oxide layer on aluminum, improving its corrosion resistance and enhancing its surface finish with a matte or glossy appearance.

Metal Bending Capabilities

Specification | Description |

Maximum Part Size | 1.5 m x 1.5 m |

Metal Bending Forces | Up to 1000 tons |

Bending Line Length | Up to 7200 mm |

Bending Thickness | Up to 60 mm |

General Tolerances | Our metal bending standards follow ISO 2768. |

Bend to Edge/Hole, Single Surface | +/- 0.254 mm (+/- 0.010 in.) |

Bend Radius | Equal to material thickness |

Bend Angle | +/- 1° |

Bend Cutting Area | Up to 4000 mm |

Lead Time | 5 days or more |

Metal Bending Workshop

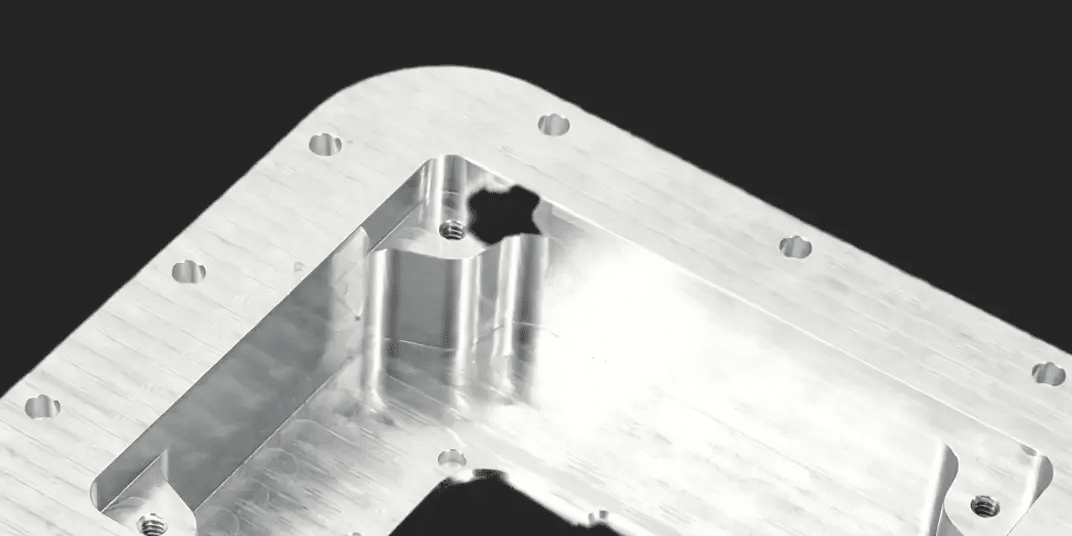

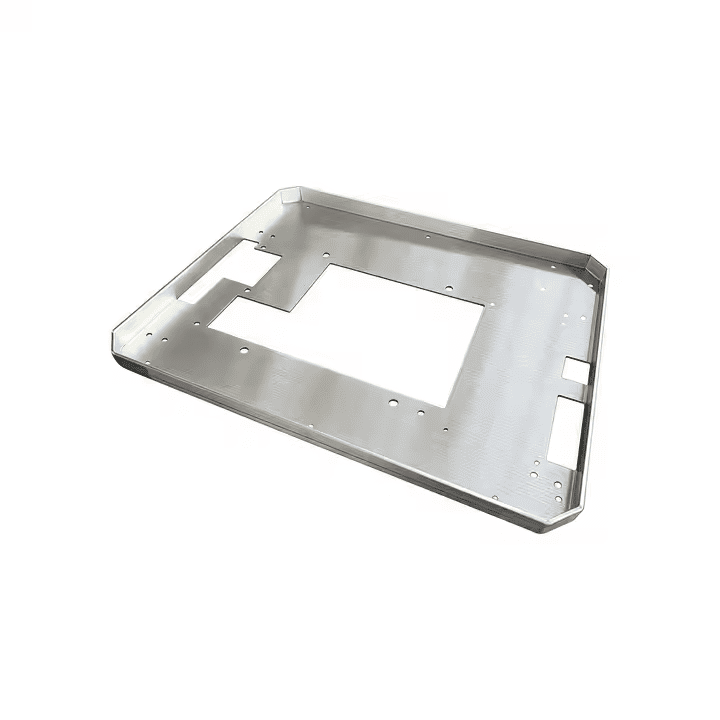

Metal bending transforms flat sheets into 3D shapes by applying precision force, using advanced machinery to create bends at designated angles. Prior to bending, flat sheets are prepared through cutting methods like laser cutting, ensuring high accuracy. We utilize high-tonnage equipment, capable of applying up to 1000 tons of force, and can handle materials with lengths up to 7200mm. Each bend is executed using a precise mold with a range from R3 to R50, guaranteeing accuracy with a machining tolerance of ± 0.1mm.

This process is ideal for various applications, including machinery components, architectural features, and custom designs. Our custom metal bending services offer tailored solutions with high precision and consistency.

Advantages

Advantages of Metal Bending Manufacturing

Metal bending is a vital process across various industries, offering several key advantages:

- Cost Efficiency:By reducing the need for multiple parts and welds, metal bending helps minimize both labor and material costs. Simplifying designs into single, continuous pieces reduces assembly time and lowers overall project expenses.

- Enhanced Strength: The bending process naturally increases the strength along the bend, making parts more durable and able to withstand greater loads. This built-in reinforcement allows for lighter and thinner constructions without sacrificing structural integrity.

- Precision and Flexibility: With advanced CNC bending technology, we achieve high precision and repeatability, ensuring every part meets exact specifications. The ability to bend various materials, including aluminum, steel, and copper, makes this process adaptable to a wide range of applications, from industrial machinery to custom automotive components.

- Aesthetic Improvement: Metal bending can produce clean, smooth lines and curves, enhancing the visual appeal of parts. This is especially valuable for visible components like fixtures and furniture, where appearance is as important as functionality.

- Rapid Production: CNC bending processes significantly reduce production cycles, allowing for faster turnaround times from design to finished product. This speed makes it ideal for industries that need quick responses to evolving market demands.

Applications

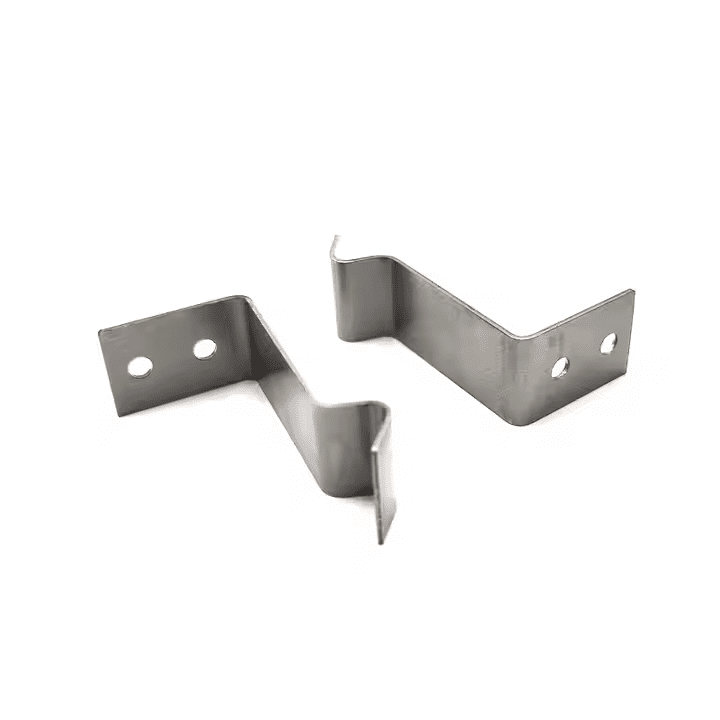

Applications of Bent Metal Parts

Bent metal parts are used in a variety of applications, transforming flat sheets into durable and functional components:

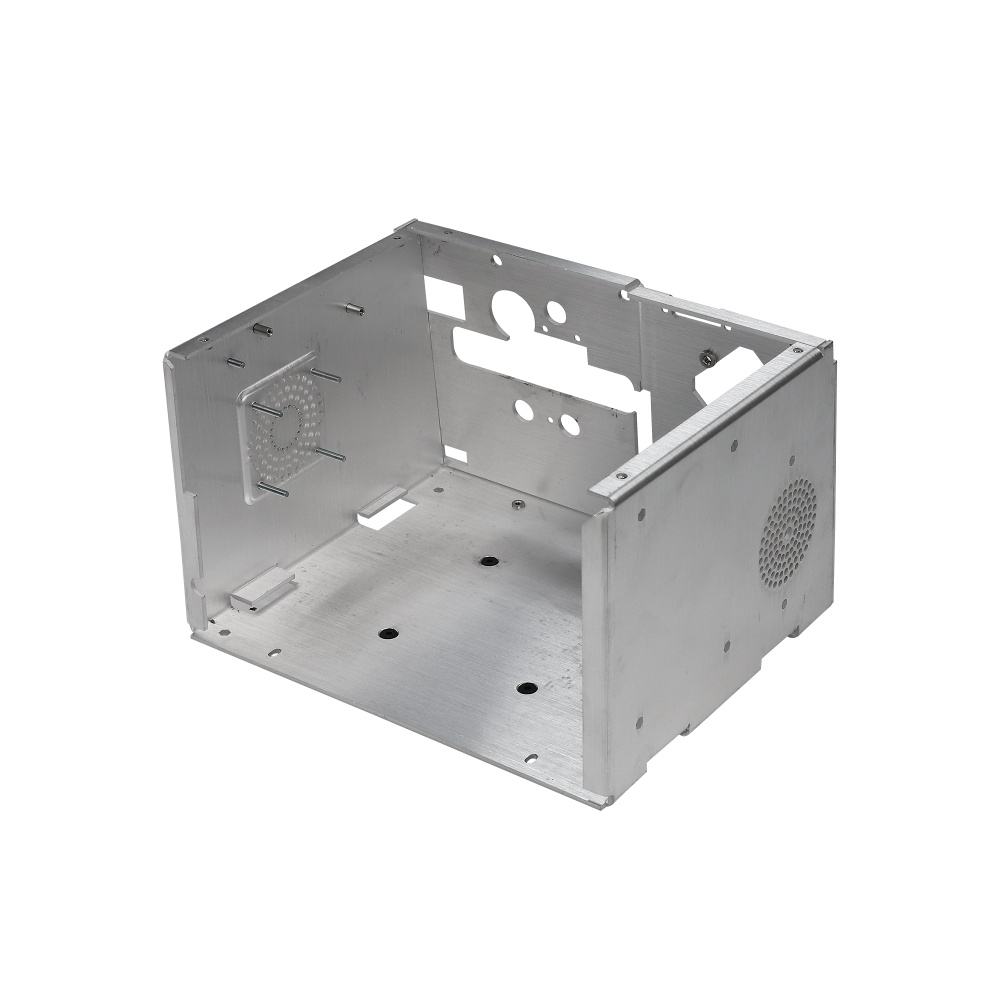

- Enclosures and Casings: Custom bent enclosures protect everything from electronics to industrial machinery, providing security, support, and maintaining accessibility while enhancing aesthetic appeal.

- Brackets and Mounts: Precision bending produces strong brackets and mounts that are vital for mounting systems, ensuring components are securely fastened in both commercial and residential settings.

- Panels and Doors: Metal bending allows for the creation of panels and doors, from visually appealing architectural elements to functional barriers, with custom dimensions and designs to fit specific needs.

- Frames and Beams: Structural frames and beams gain strength and rigidity through metal bending, making them essential for supporting buildings, machinery, and automotive structures.

- Complex Geometries: Advanced CNC bending technology facilitates the creation of components with intricate geometries, meeting the demands of modern designs that require high precision and unique shapes.

CNC Machining FAQs

How does CNC bending improve precision?

Can Lewei Precision handle both prototypes and large production runs?

Yes, Lewei Precision specializes in both low-volume prototypes and high-volume production, delivering quick turnaround times while maintaining top-quality standards for every batch.

What is the maximum size for parts you can bend?

What is the typical lead time for metal bending projects?

Our standard lead time for custom bent metal parts is 5 days, depending on complexity and order volume. Expedited services are available for urgent needs.