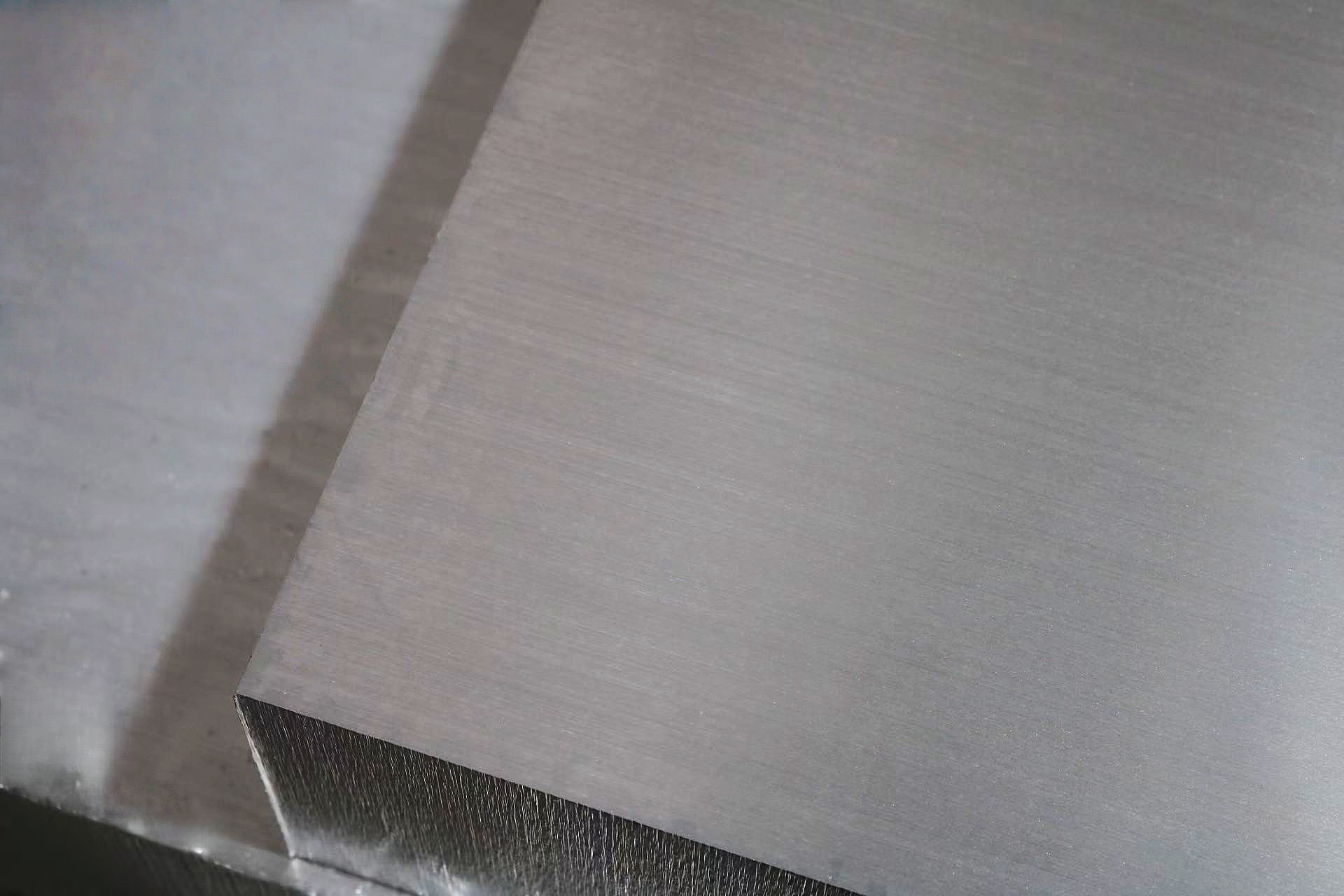

The 7075-T651 Aluminum Plate is one of the strongest aluminum alloys available, offering exceptional mechanical properties and excellent weight-to-strength performance. It is widely used in aerospace, defense, and high-stress structural applications where strength and reliability are critical.

Our 7075-T651 Aluminum Plate is a heat-treated, stress-relieved alloy known for its outstanding strength, toughness, and fatigue resistance. With zinc as the primary alloying element, 7075-T651 delivers strength comparable to many steels while maintaining a much lower weight — making it ideal for weight-sensitive, high-performance designs.

This alloy is particularly well-suited for aerospace components, defense equipment, and precision-engineered tooling. Its T651 temper means it has been solution heat-treated, stress-relieved by stretching, and artificially aged, ensuring maximum dimensional stability during machining.

We offer precision-cut plates in multiple thicknesses, with strict quality control to guarantee consistency. The 7075-T651 Aluminum Plate is the preferred choice for demanding applications requiring high strength, excellent machinability, and superior fatigue resistance

| Parameter | Details |

|---|---|

| Alloy Type | 7075 Aluminum |

| Temper | T651 |

| Thickness Range | 6 mm – 200 mm |

| Width Options | Up to 2200 mm |

| Length Options | Custom cut-to-size available |

| Tensile Strength | 510 – 560 MPa |

| Yield Strength | ≥ 430 MPa |

| Density | 2.81 g/cm³ |

| Hardness | 150 HB (approx.) |

| Corrosion Resistance | Good (better with protective coating) |

| Machinability | Excellent |

| Applications | Aerospace parts, defense components, automotive racing parts, molds, tooling, high-performance structures |

Lewei Precision provides a range of manufacturing capabilities to support rapid prototyping and both low and high-volume production needs. With our own factory and a reliable Chinese network, we deliver complex, high-quality parts efficiently.

Precision die casting services for aluminum, zinc, magnesium, and copper parts, with tolerances as tight as ±0.03″ for high-volume production.