Lewei Precision As Machined Services

As Machined Overview

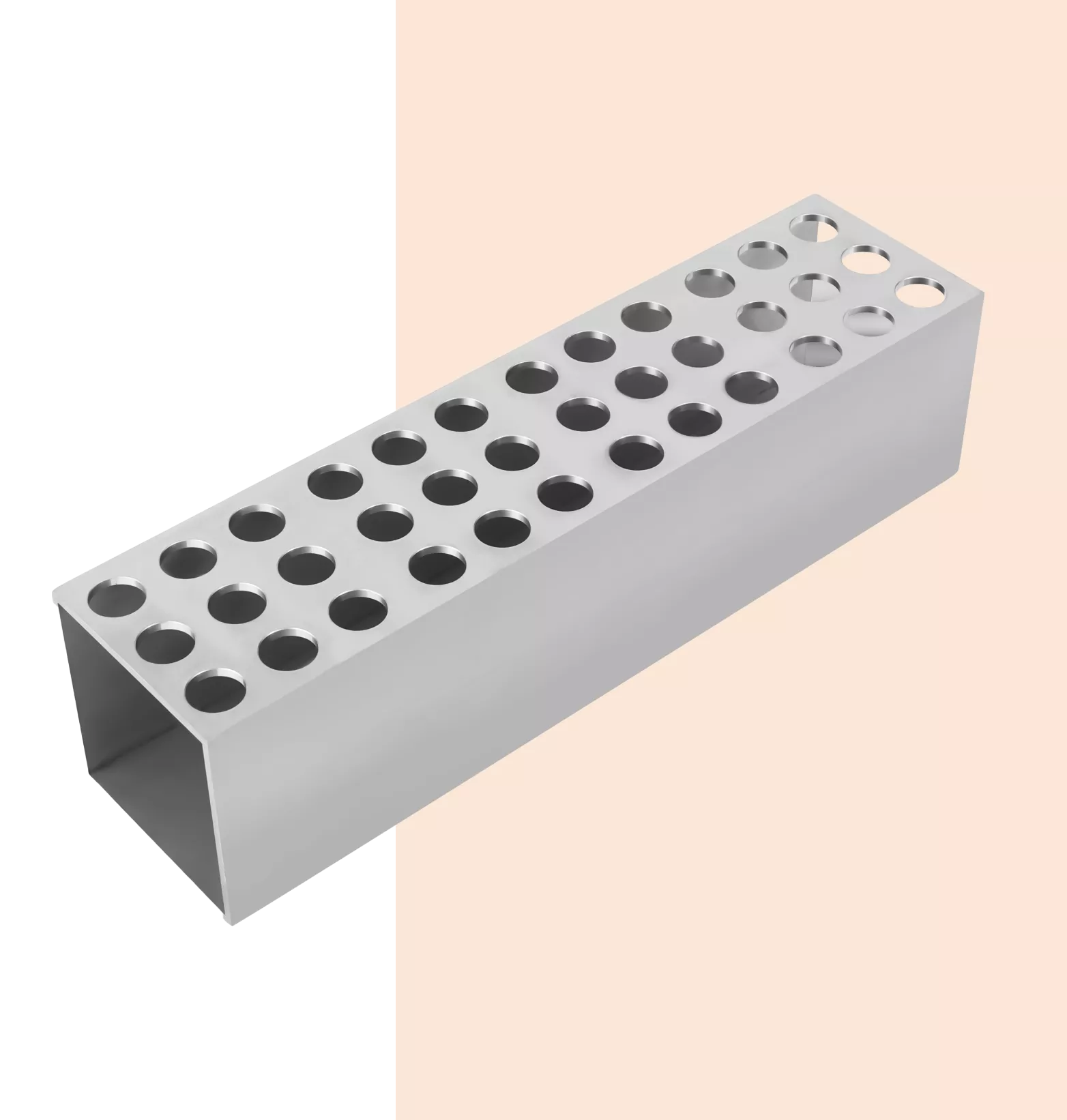

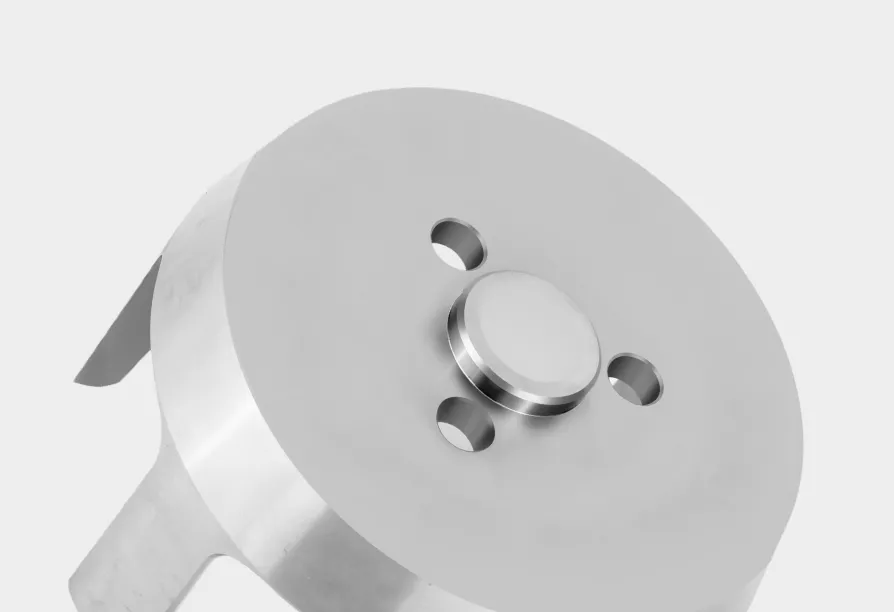

Parts with as-machined surface finish are characterized by visible tool markings with a surface roughness depending on the machine tool, cutting parameters, tool paths, and the operator’s expertise.

This surface finish is what you get after freshly machining a part without subjecting it to additional processing like honing, grinding, and other surface finishing treatments.

As machined services deliver a machined surface finish, the most convenient option for parts needing tight tolerance and reduced manufacturing cost.

Advantages of As Machined Surface Finish

- Faster production time because it does not require extra finishing steps

- It preserves the workpiece’s integrity and retains its natural look

- Extensive machining material supports

- Suitability for parts with strict dimensional tolerances.

- Cost-effectiveness because the surface finish does not require additional processing

Notes

- A finishing cutting pass can be applied to reduce the roughness of a surface down to 0.8 or 0.4 μm.

As Machined Design Considerations

- Simplify the Part Geometry: Avoid complex part design and reduce tight tolerance when feasible to facilitate a smoother machining operation and reduce surface imperfections.

- Optimize Tooling and Toolpaths: Use sharp and high-quality tools and carefully planned tool paths to minimize vibrations and enhance cutting efficiency, which can affect the surface finish.

- Select Machinable Materials: Use CNC machining materials with excellent machinability and favorable surface finish properties.

Surface Finishing Resources

FAQs

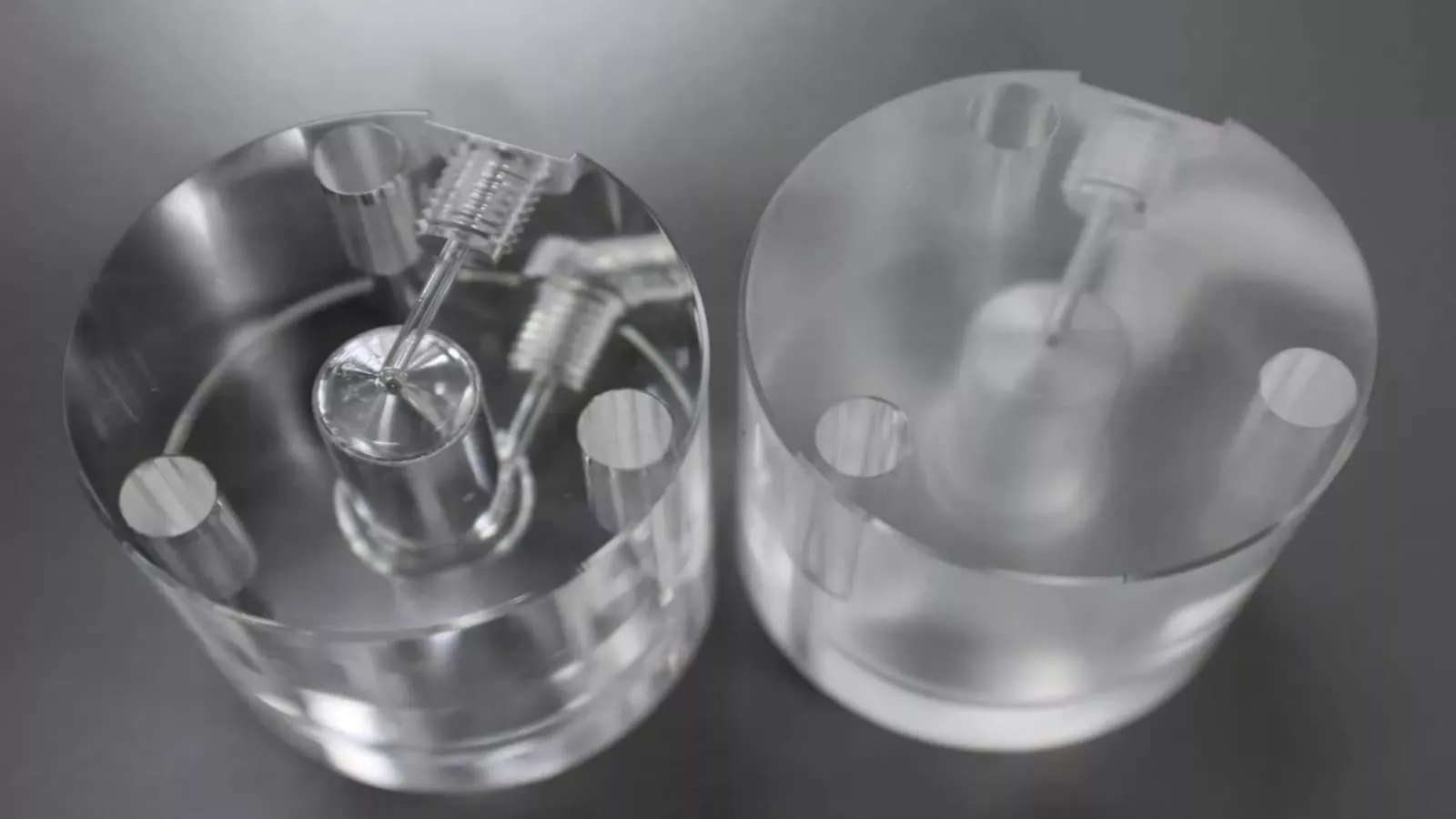

How do you ensure mold accuracy and consistency during production?

We use advanced CNC machining and precision inspection tools like CMM to maintain tight tolerances and ensure consistency throughout production.

What is the role of cooling channels in injection mold tooling?

Cooling channels regulate the mold temperature, improving cycle times and ensuring uniform part cooling to prevent defects like warping.

Can Lewei Precision create molds for multi-material injection molding (2K molding)?

Yes, we can design molds for 2K molding, allowing the combination of two materials into one part, which improves functionality and reduces assembly steps.

How does Lewei Precision handle complex part geometries in mold design?

We use advanced CAD software and 3D modeling to design molds that accommodate complex geometries, undercuts, and intricate details for precise part production.